Plastic-sleeve bamboo-reinforcement cemented soil pile and construction method thereof

A technology of plastic sleeves and cement-soil piles, which is applied in the field of cement-soil piles, can solve the problems of tight construction period, great influence of the surrounding environment, poor adaptability, etc., increase pile side friction resistance, solve uneven settlement, and simple construction method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

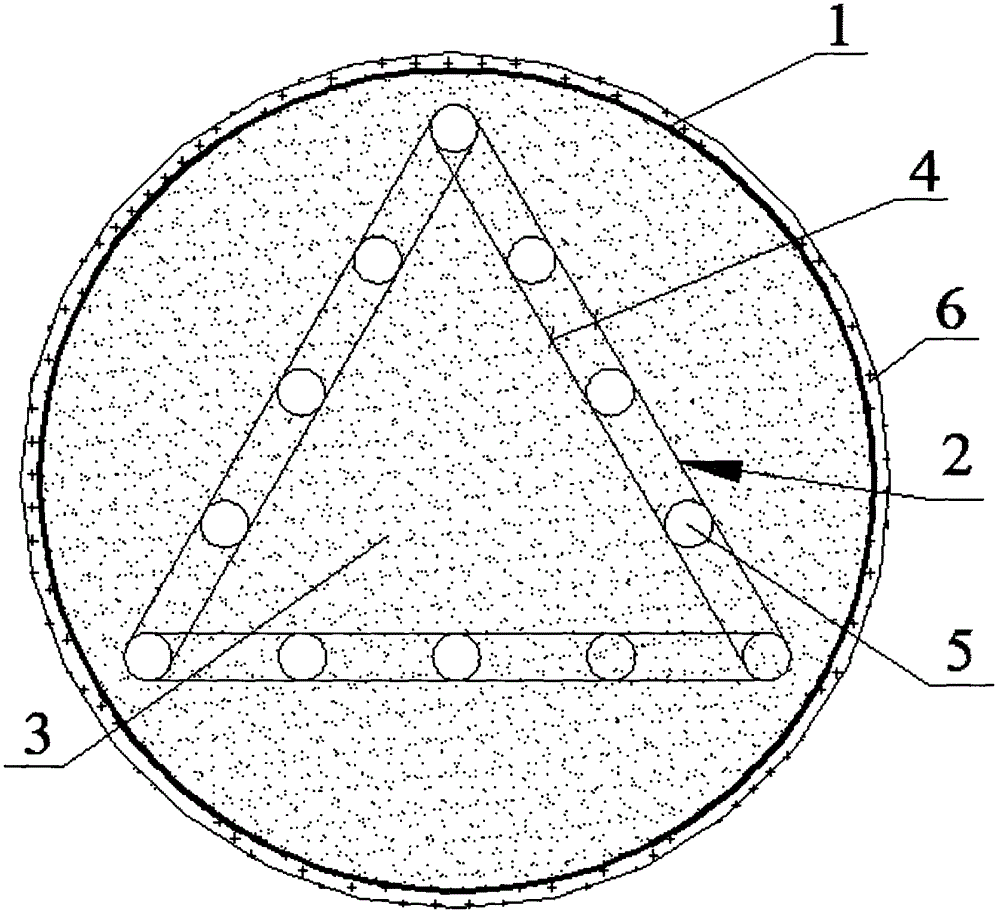

[0022] The present invention will be described below with reference to the drawings.

[0023] As attached figure 1 , 2 The plastic-sleeved bamboo-reinforced cement-soil pile of the present invention is a new type of foundation treatment method in soft soil layers. The plastic casing bamboo-reinforced cement-soil pile is mainly composed of 3 parts, including: (1). Plastic casing 1: Plastic casing 1 placed in the formation after reaming through the sinking pipe. The diameter of the plastic casing can be 160mm. -1000mm, the length is determined by the depth of the treated foundation; the inside and outside of the plastic casing can be made into threaded surfaces, which effectively increase the pile side friction resistance and increase the friction and occlusion of the soil inside and outside the plastic casing; plastic The casing can be made of PVC, PPR, ABS, PE and other plastic pipes. figure 1 What is described here is a single-layer plastic sleeve structure, a cylindrical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com