A steel-ultra-high-performance concrete composite continuous beam bridge structure and its construction method

An ultra-high-performance, high-strength concrete technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of cracking prestressing efficiency, low and other problems, and achieve the effect of improving tensile performance, simple construction, and improving tensioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

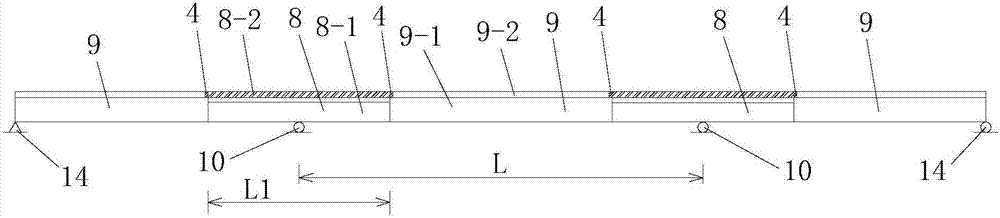

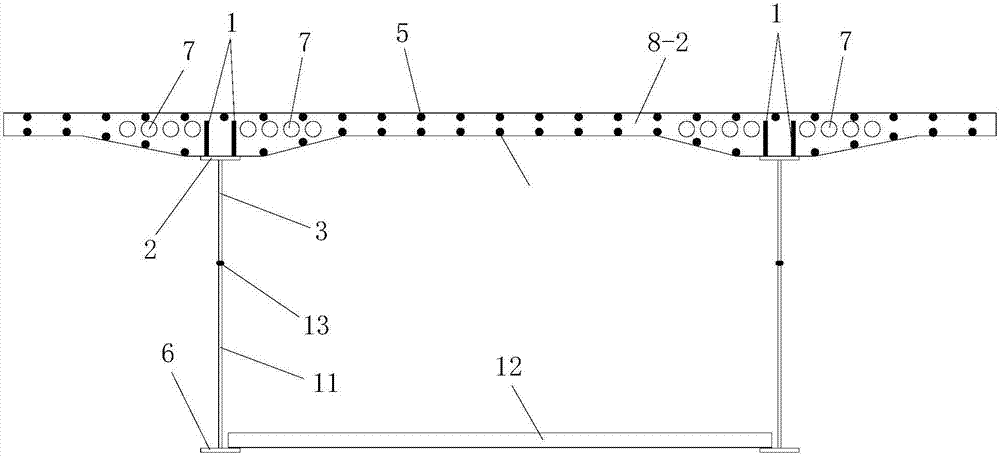

[0057] Such as figure 1 A steel-ultra-high-performance concrete composite continuous beam bridge structure shown includes a continuous beam formed by splicing M steel-ultra-high-performance concrete composite beam sections 8 and M+1 steel-high-strength concrete composite beam sections 9, The steel-ultra-high-performance concrete composite beam sections 8 and the steel-high-strength concrete composite beam sections 9 are arranged in a staggered manner, wherein M is a positive integer and M≥2; the M steel-ultra-high-performance concrete composite beam sections 8 are respectively Supported on the M piers 10 of the continuous girder bridge being constructed.

[0058] The steel-high-strength concrete composite beam section 9 includes a first steel beam section 9-1 and a high-strength concrete slab 9-2 laid on the first steel beam section 9-1 and formed by pouring high-strength concrete.

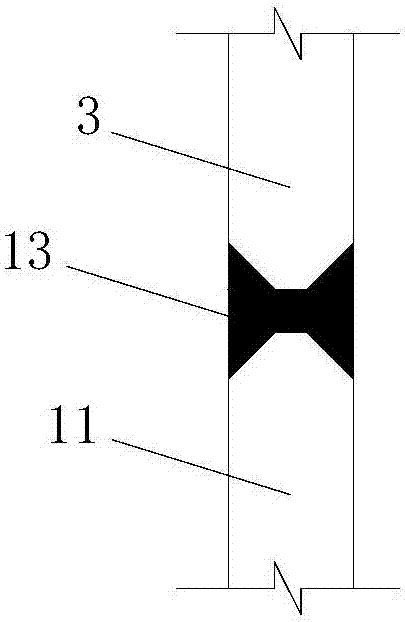

[0059] to combine figure 2 , the steel-ultra-high-performance concrete composite beam secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com