Low-friction nanometer TaC-reinforced carbon-based composite film preparation method

A low-friction, thin-film technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of self-lubricating field research and application, etc., to improve tribological properties, good stability, and preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: (C-TaC hard film with a TaC content of 92.3 wt.%)

[0031]A graphite plate with a length of 10cm and a width of 5cm is used as the deposition substrate. Before deposition, it is polished, chamfered, cleaned, and dried, and then placed in the constant temperature area of a hot-wall chemical vapor deposition furnace. The furnace is sealed and vacuumed to below 100pa. , heat up to a temperature of 900~1200°C and keep warm. The chemical vapor deposition process adopted is as follows: the deposition temperature is 1100 °C, the deposition pressure is 500-600 Pa, the deposition time is 6 h, and the reaction gas system used is TaCl 5 -C 3 h 6 -Ar, where the flow rate of propylene is 0.1L / min, and the flow rate of carrier gas argon is 0.4L / min -1 , and pass into the hot wall CVD furnace with a constant gas ratio.

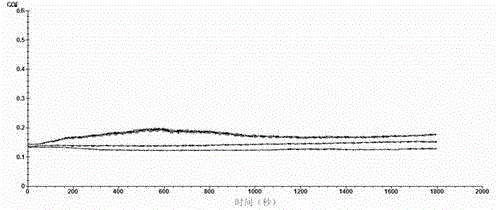

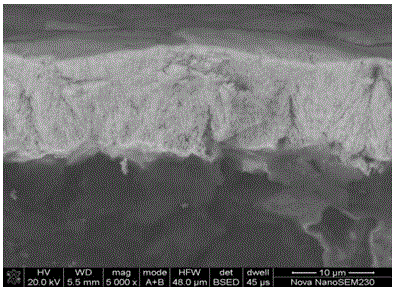

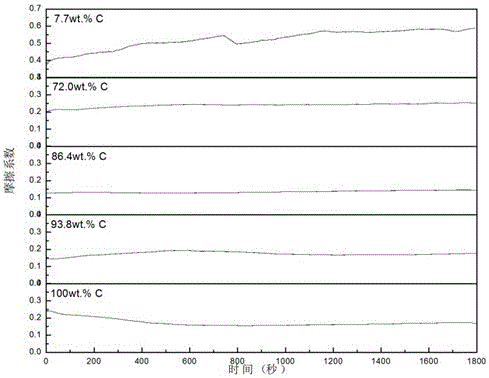

[0032] After deposition, the phase composition of the film mainly includes C phase (7.7 wt.%) and TaC phase (92.3 wt.%); the film is uniform and dens...

Embodiment 2

[0034] Example 2: (C-TaC hard film with TaC content of 86.4wt.% and 72.0wt.%)

[0035] Among them, the composition ratio of the first C-TaC composite film is TaC content 28.0wt%, C content 72.0wt%. 6h, the reaction gas system used is TaCl 5 -C 3 h 6 -Ar, wherein the flow rate of propylene is 1.2 L / min, and the flow rate of carrier gas argon is 0.4 L / min; and it is passed into the hot wall CVD furnace with a constant gas ratio.

[0036] The composition ratio of the second C-TaC composite film is TaC content 13.6wt%, C content 86.4wt%, the chemical vapor deposition process used is, the deposition temperature is 1100°C, the deposition pressure is 500-600Pa, and the deposition time is 6h , the reaction gas system used is TaCl 5 -C 3 h 6 -Ar, wherein the flow rate of propylene is 1.2L / min, and the flow rate of carrier gas argon is 0.2 L / min; and it is passed into the hot wall CVD furnace with a constant gas ratio and constant volume.

[0037] After deposition, the phase comp...

Embodiment 3

[0040] Example 3: (Comparison between C-TaC composite film and other films)

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com