Desulfurization process and desulfurizer

A desulfurizer and desulfurizer technology, applied in the field of desulfurization and desulfurizers, can solve problems such as poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in each drawing, the same reference numerals are assigned to the same or corresponding parts, and overlapping descriptions will be omitted.

[0050] [Preparation of nickel oxide catalyst]

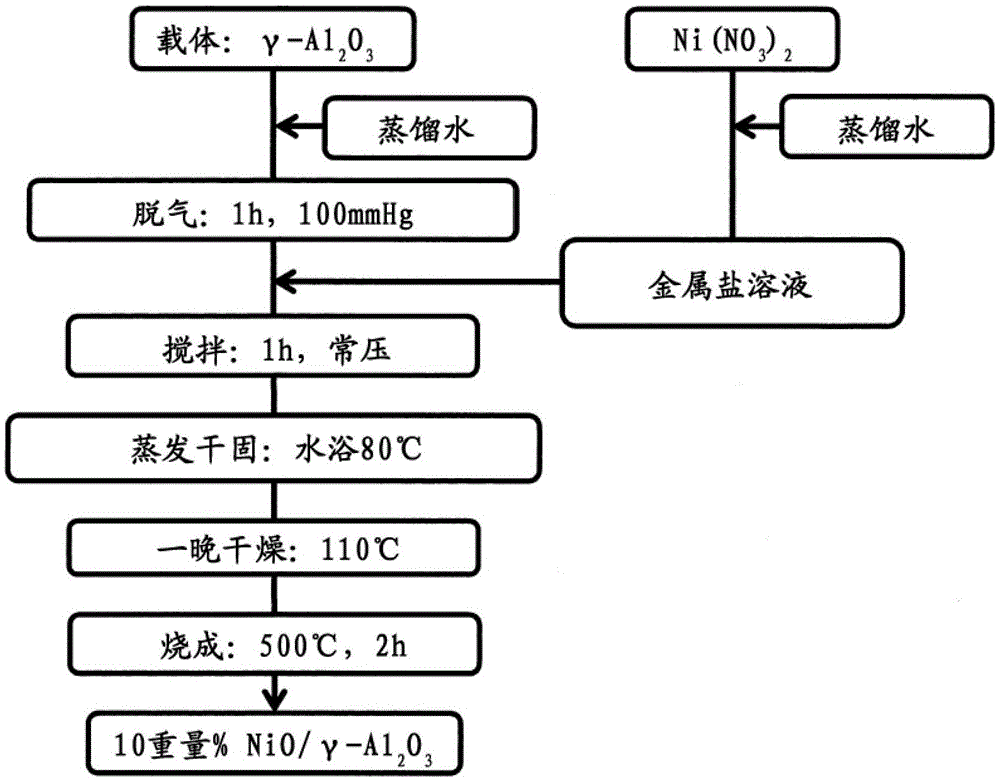

[0051] figure 1 It is a diagram showing an example of a preparation procedure of a nickel oxide catalyst.

[0052] First, γ-Al 2 o 3 Distilled water was added, and deaeration was performed at 100 mmHg for 2 hours.

[0053] Then, a nickel nitrate aqueous solution manufactured by Wako Pure Chemical Industries, Ltd. was added, followed by stirring for 1 hour.

[0054] Next, it was evaporated to dryness at 80° C. for 2 hours at 200 mmHg, dried at 110° C. overnight, and fired at 500° C. for 2 hours.

[0055] Furthermore, NiO / γ-Al containing 10% by weight of nickel in terms of metallic nickel was prepared. 2 o 3 (hereinafter referred to as "10% by weight NiO / γ-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com