Method for in-situ preparation of porous structure zinc oxide nanometer rod array

A technology of zinc oxide nanorods and porous structure, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., to achieve the effect of high purity, large specific surface area, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

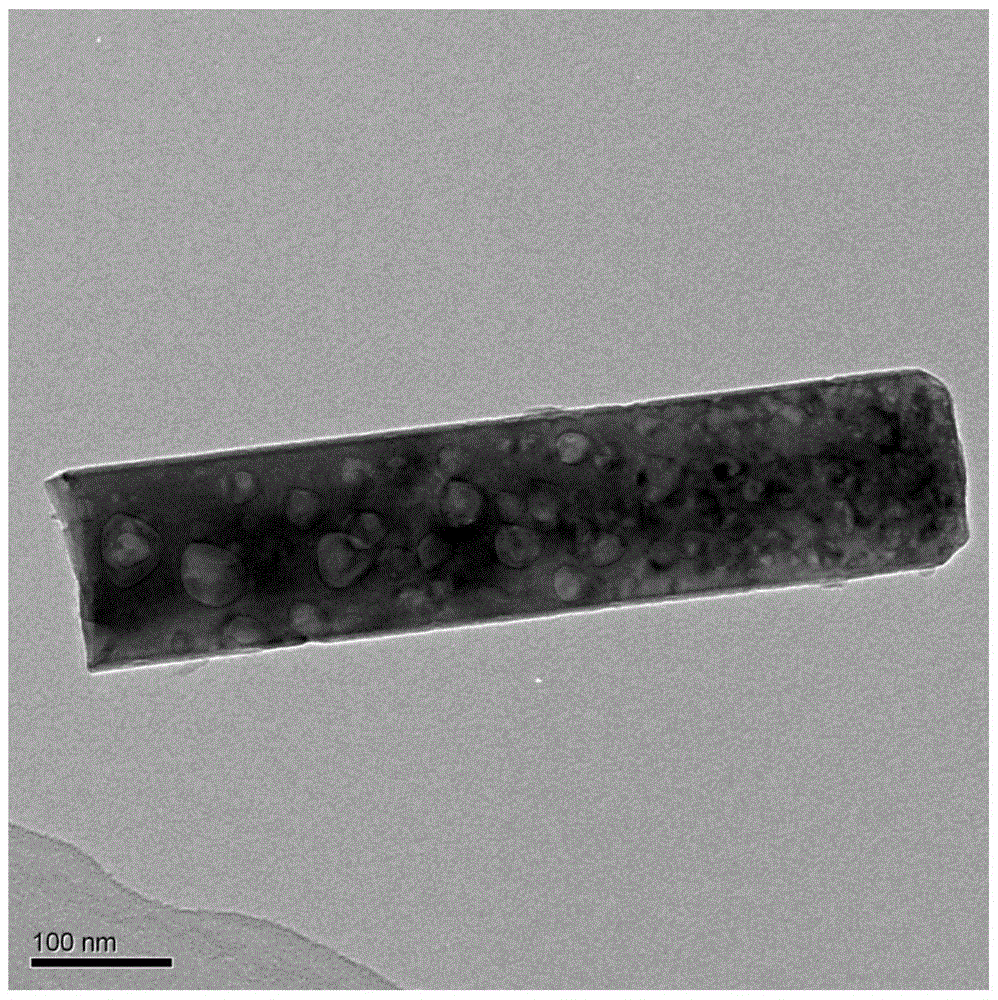

Image

Examples

Embodiment 1

[0025] (1) Preparation of zinc oxide precursor solution: Weigh 5.4876g of zinc acetate dihydrate, dissolve it in 50mL of methanol organic solvent and stir for 20 minutes, then weigh 1.9270g of ammonium acetate and add it to the above solution, and stir on a magnetic stirrer for 25 minutes to form A transparent homogeneous sol, from which a zinc oxide precursor solution is prepared.

[0026] (2) Cleaning of the deposition substrate: the FTO conductive glass substrate (SnO doped with fluorine 2 Transparent conductive glass) after cleaning with detergent, put them in absolute ethanol, deionized water, and absolute ethanol in order to ultrasonically clean for 30 minutes.

[0027] (3) Immersion and pulling of the deposition substrate to form a film: dry the cleaned FTO conductive glass substrate and place it on the clamp of the pulling machine, and dip the FTO conductive glass substrate in the In the prepared zinc oxide precursor solution, the immersion time is 1 minute. After th...

Embodiment 2

[0033] (1) Preparation of zinc oxide precursor solution: first mix zinc acetate dihydrate and methanol to form a methanol solution of zinc acetate dihydrate with a concentration of 0.5mol / L, then add ammonium acetate to obtain a zinc oxide precursor solution, ammonium acetate The molar ratio to zinc acetate dihydrate is 1:1.

[0034] (2) Cleaning of the deposition substrate: After the deposition substrate is FTO conductive glass, it is cleaned with detergent, followed by ultrasonic cleaning with absolute ethanol, deionized water, and absolute ethanol for 60 minutes.

[0035] (3) Immersion and pulling of the deposition substrate to form a film: dry the cleaned FTO conductive glass substrate and place it on the clamp of the pulling machine, and dip the FTO conductive glass substrate in the prepared film at a pulling speed of 2 mm / s. In a good zinc oxide precursor solution, the immersion time is 2 minutes. After the first pull is completed, take out the FTO conductive glass subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com