Production process of rubber diaphragm in automobile brake air chamber

A technology of rubber diaphragm and automobile brake, which is applied in the field of automobile brake system, and can solve the problems of difficult operation, wrinkling, and inability to be evenly centered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

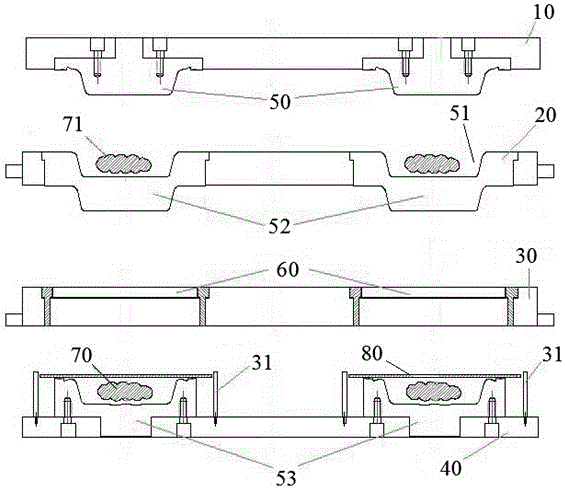

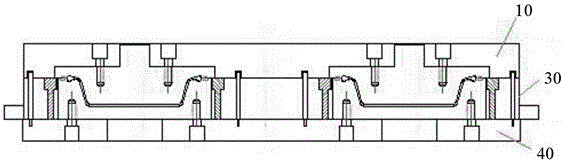

[0038] A rubber extrusion molding machine and a laser cutting machine are used to prepare the upper rubber block 71, the lower rubber block 70 and the regular cloth 80. The quality of the upper rubber block 71 and the lower rubber block 70 can be different, and an automatic flat vacuum is used. The vulcanization press and corresponding molds are used to vulcanize the rubber diaphragm. The upper rubber layer of the rubber diaphragm has a separate vulcanization time T1=10s, while the lower rubber layer material and cloth vulcanization time T1=10 seconds, the upper rubber layer and the lower rubber layer- The cloth fusion body is fully vulcanized for T2=255s, the vulcanization temperature is 145°C, the holding pressure is 19Mpa, and each time vulcanization is vacuumed for 10 seconds, holding pressure twice, and exhausted twice.

Embodiment 2

[0040] For preliminary preparations, refer to Example 1. The vulcanization time of the upper rubber layer of the rubber diaphragm is T1=12s, and the vulcanization time of the lower rubber layer material and the cloth is T1=12 seconds, and the upper rubber layer and the lower rubber layer-cloth fusion are fully vulcanized T2=258s, vulcanization temperature is 152℃, holding pressure is 18Mpa, and each time vulcanization is evacuated for 11 seconds, holding pressure three times, and exhausting twice.

Embodiment 3

[0042] For the preliminary preparation, refer to Example 1. The vulcanization time of the upper rubber layer of the rubber diaphragm is T1=15s, and the vulcanization time of the lower rubber layer material and the cloth is T1=15 seconds, and the upper rubber layer and the lower rubber layer-cloth fusion are fully vulcanized T2=262s, the vulcanization temperature is 162℃, the holding pressure is 20Mpa, and each time the vulcanization is carried out, vacuum is applied for 10 seconds, pressure is maintained twice, low pressure stays 0.8s, and exhausted three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com