Sheet Metal Coordinate Grid Stamping Die

A coordinate grid, metal sheet technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low grid accuracy, high scrap rate, grid damage, etc. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

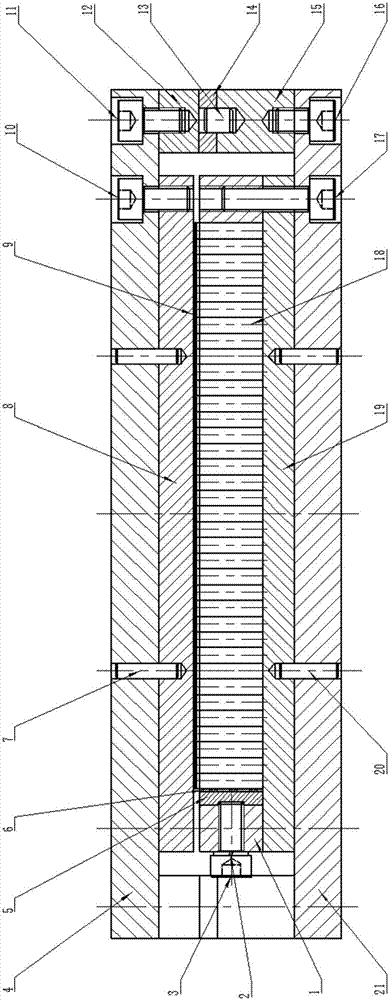

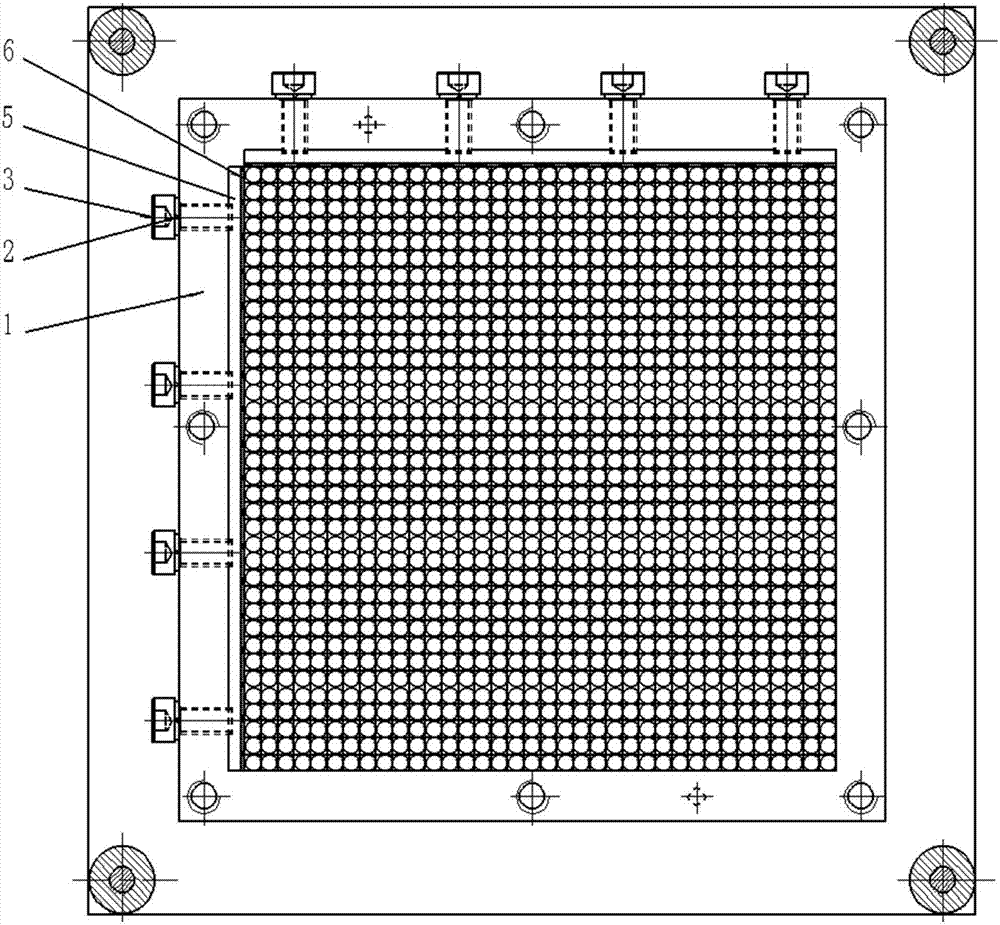

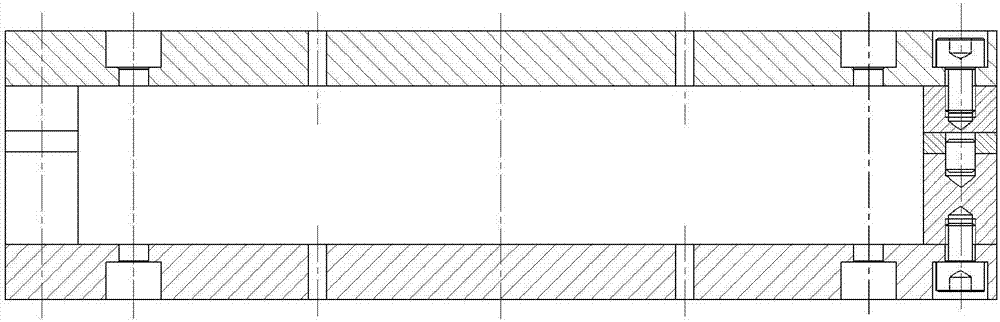

[0039] The specific structure of the present invention and its implementation will be further described below through examples and with reference to the accompanying drawings.

[0040] like figure 1 As shown, the metal sheet coordinate grid stamping die described in the patent of the present invention is composed of the following parts: ring fixing plate 1, spring washer 2, fastening bolt 3, upper template 4, clamping plate 5, rubber pad 6 , upper mold positioning pin 7, upper mold backing plate 8, sheet material 9, fastening bolt 10, fastening bolt 11, upper mold support block 12, upper and lower mold positioning pin 13, ring limit block 14, lower mold support block 15 , Fastening bolt 16, fastening bolt 17, punch 18, lower mold backing plate 19, lower mold positioning pin 20, lower template 21.

[0041] like figure 1 As shown, the metal sheet coordinate grid stamping die punch 18 described in the patent of the present invention is designed by the customer according to spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com