Preparation method and application of fe3o4@sio2 egg yolk-eggshell hollow composite microspheres

A technology of composite microspheres and eggshells, applied in the field of biomedical materials, can solve the problems of unfavorable magnetic particle distribution, affecting bearing capacity, reducing biocompatibility, etc., achieving good drug release performance and ensuring the effect of high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

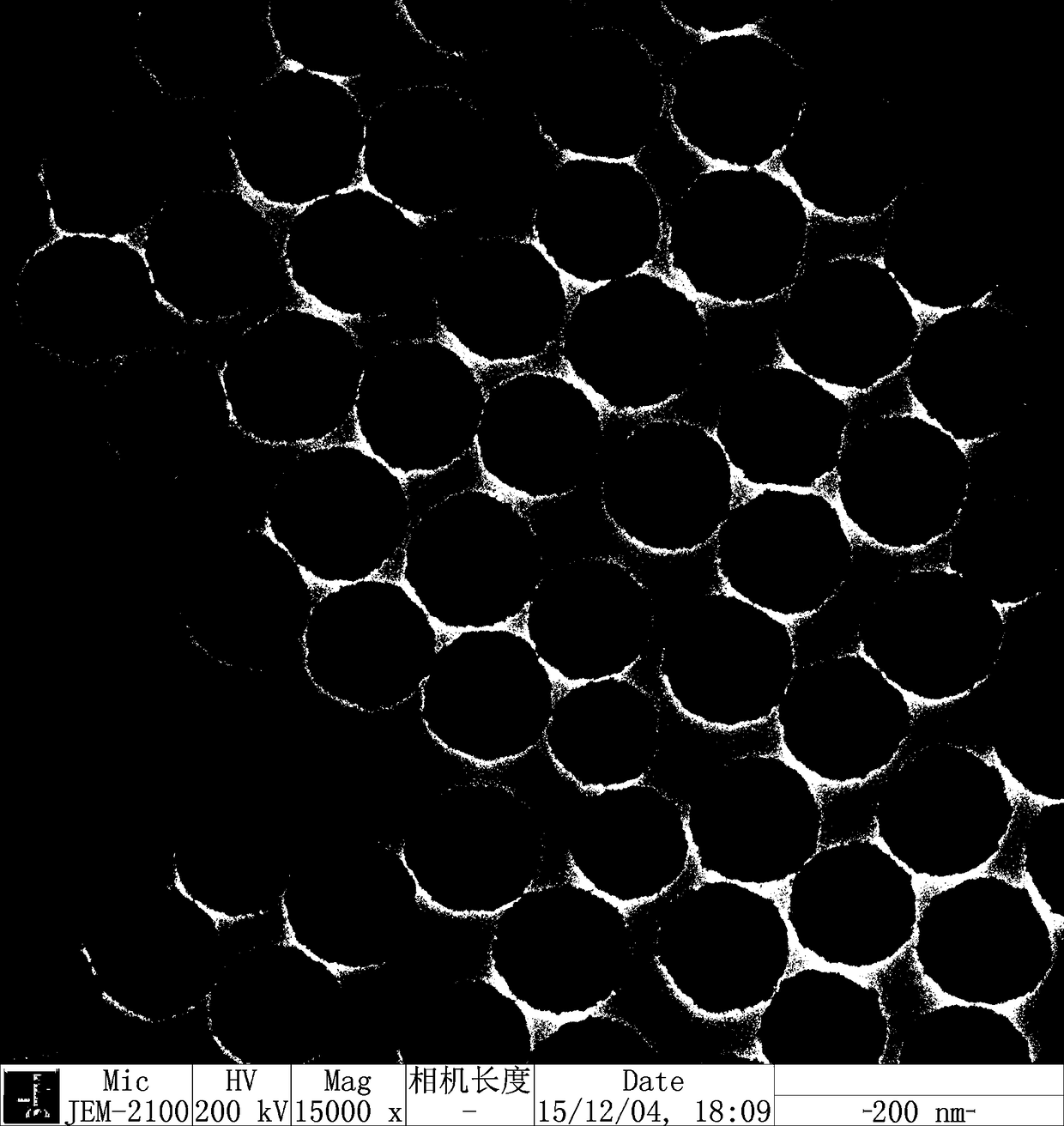

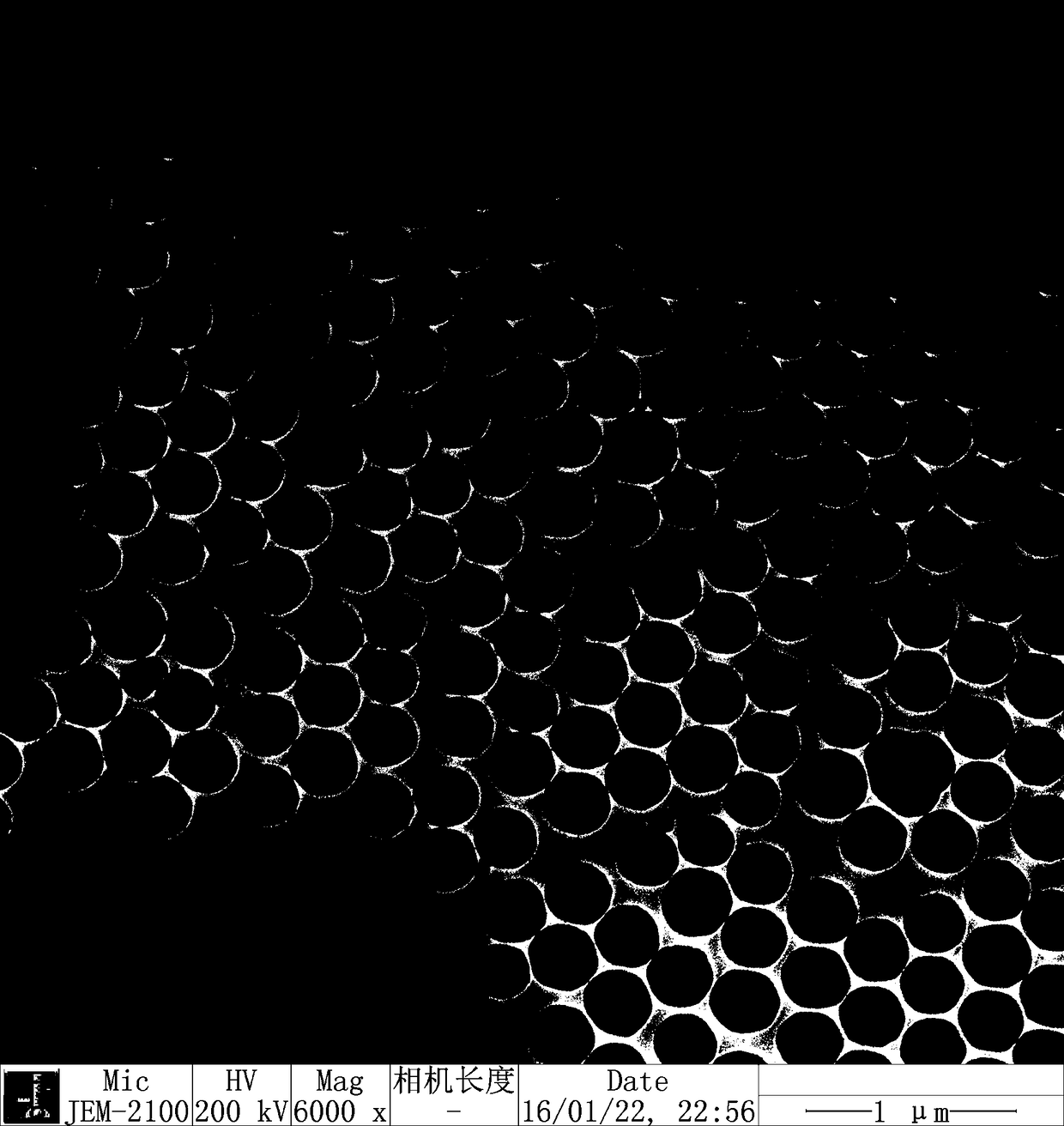

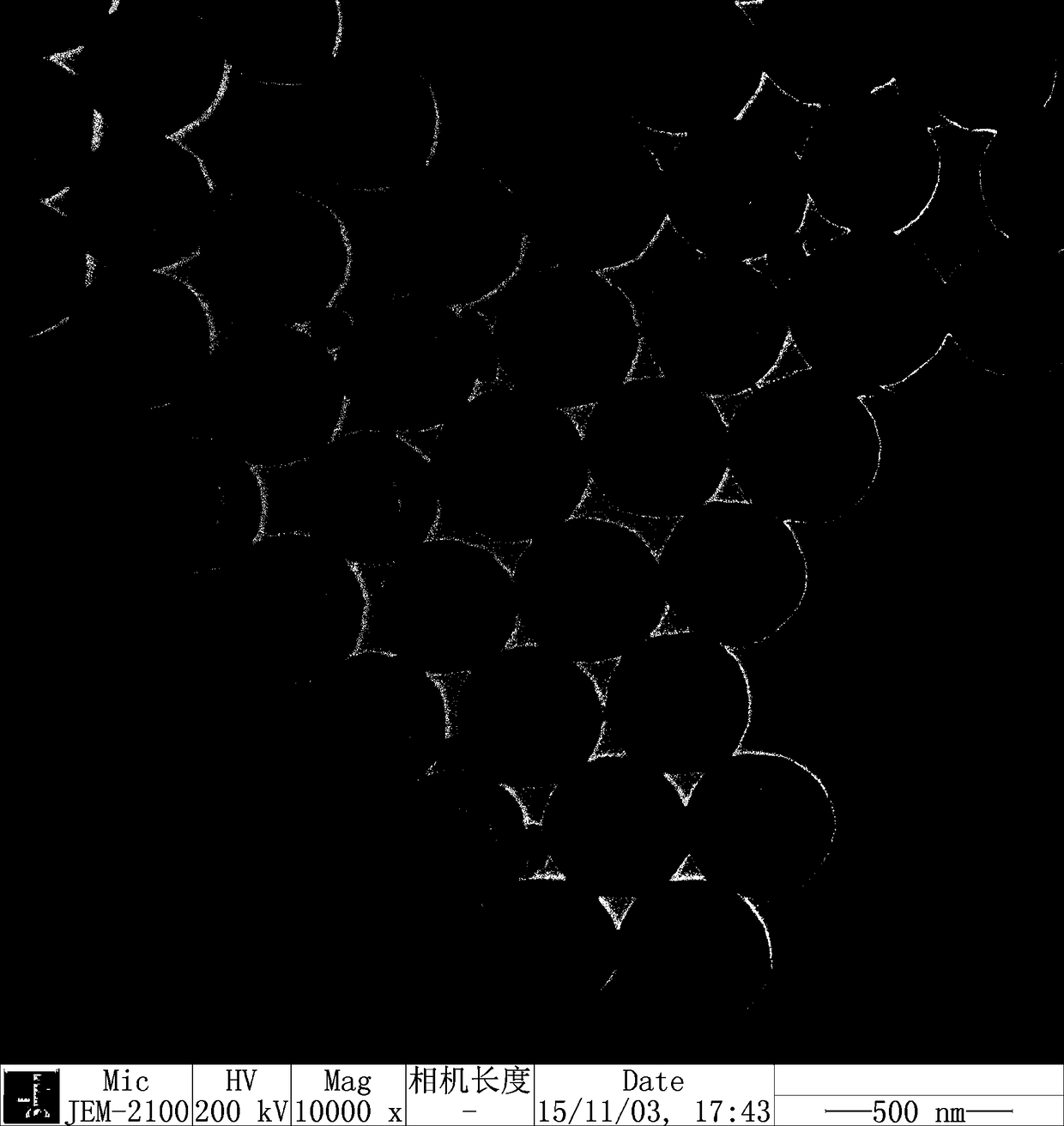

[0025] a kind of Fe 3 o 4 @SiO 2 The preparation method of egg yolk-eggshell structure hollow composite microspheres comprises the following steps: ① FeCl 3 •6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 190°C for 3.5h, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol washed, washed with water, and then dried at 60°C to obtain Fe 2 o 3 Nano microspheres; ② the Fe prepared by step ① 2 o 3 Nanospheres were dispersed into 60vol% ethanol at a solid-to-liquid ratio of 1:250, added with ethanol solution of TEOS (tetraethyl orthosilicate), ultrasonically treated at 25°C for 3 hours, then ammonia water was added, stirred for 3 minutes, and reacted at room temperature for 2 hours. The obtained solid was washed with ethanol, then washed with water, and then dried at 60°C to obtain Fe 2 o 3 @SiO...

Embodiment 2

[0041] a kind of Fe 3 o 4 @SiO 2 The preparation method of egg yolk-eggshell structure hollow composite microspheres comprises the following steps: ① FeCl 3 •6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 170°C for 3 hours, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol , then washed with water, and then dried at 55°C to obtain Fe 2 o 3 Nano microspheres; ② the Fe prepared by step ① 2 o 3 Disperse the nanospheres in 90vol% ethanol according to the solid-to-liquid ratio of 1g:200ml, add TEOS (tetraethyl orthosilicate) ethanol solution, ultrasonically treat for 4h at 20°C, then add ammonia water, stir for 1min, and react at room temperature for 3h. The resulting solid was washed with ethanol, washed with water, and then dried at 65°C to obtain Fe 2 o 3 @SiO 2 Composite microspheres; ③...

Embodiment 3

[0046] a kind of Fe 3 o 4 @SiO 2 The preparation method of egg yolk-eggshell structure hollow composite microspheres comprises the following steps: ① FeCl 3 •6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 200°C for 6 hours, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol , then washed with water, and then dried at 65°C to obtain Fe 2 o 3 Nano microspheres; ② the Fe prepared by step ① 2 o 3 Disperse the nanospheres into 10vol% ethanol according to the solid-to-liquid ratio of 1g:350ml, add TEOS (tetraethyl orthosilicate) ethanol solution, ultrasonically treat at 30°C for 2 hours, then add ammonia water, stir for 5 minutes, and react at room temperature for 1 hour. The obtained solid was washed with ethanol, then washed with water, and then dried at 55°C to obtain Fe 2 o 3 @SiO 2 Compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com