Steamed hard-breadroll forming machine

A technology of wobow head and forming machine, which is applied in the directions of dough forming and cutting equipment, dough embossing machine, dough sheeting machine/rolling machine/rolling pin, etc., can solve a lot of manpower and material resources, increase production cost and production efficiency low issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

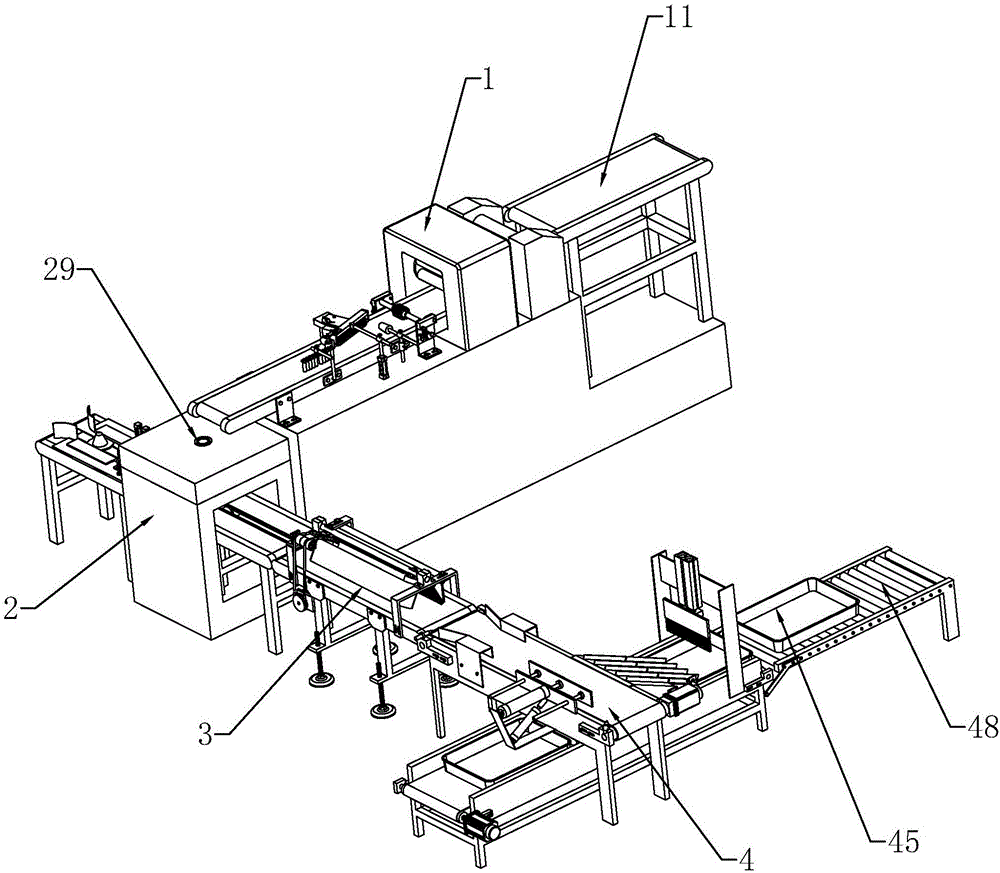

[0041] Embodiment 1: as figure 1 As shown, a steamed bun forming machine includes a face-feeding conveying device 1 connected in sequence for processing the material into strips, and a pre-pressing forming device 2 for cutting and pre-pressing the material into a cap shape with a hemispherical concave bottom , a shaping device 3 for shaping the shaped cornbread and a disk arrangement device 4 for collecting the shaped cornbough.

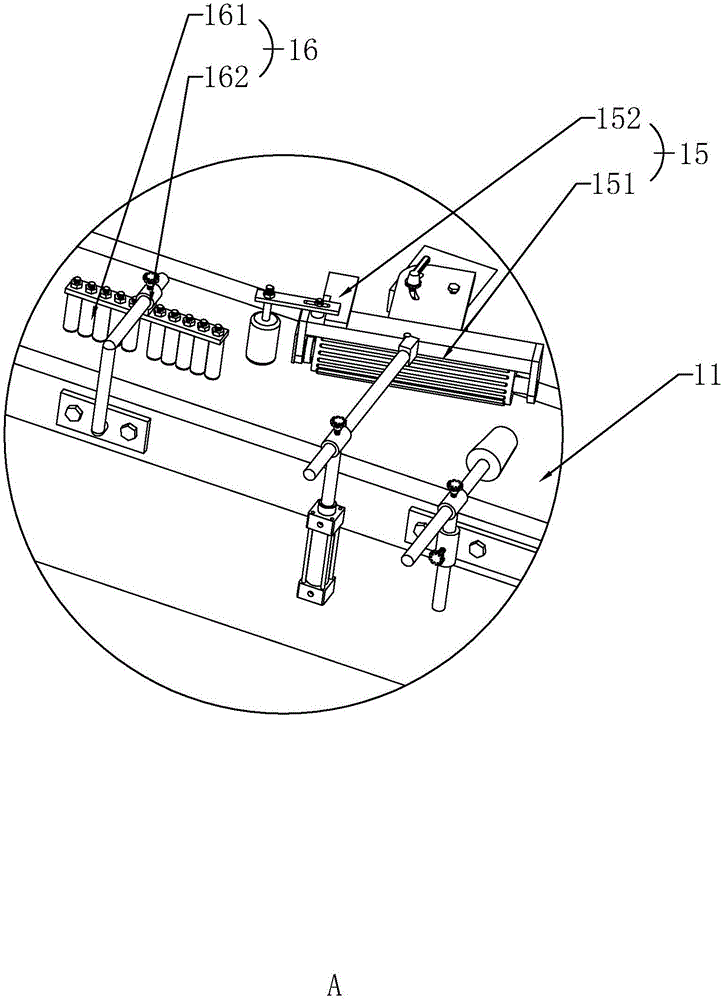

[0042] Such as figure 2 and image 3 As shown, wherein, the noodle-advancing conveying device 1 includes an noodle-advancing conveyor belt 11, a pre-pressing noodle roller 12, a lower conveying belt 13, a thinning wheel assembly 14, a rolling noodle roller assembly 15 and a guide assembly 16; the noodle-advancing conveyor belt 11 and the The pre-pressing surface roller 12 of the pressed fabric is connected, the pre-pressing surface roller 12 is composed of two transmission rollers, and the rotation direction of the two rotating rollers is opposite...

Embodiment 2

[0051] Embodiment 2: a kind of steamed bun molding process, comprising above-mentioned steamed bun forming machine, the steps are as follows:

[0052] 1) Kneading dough: Mix flour, water and seasonings to form a dough, and then knead the dough to form a flat strip.

[0053] 2) Pre-pressing: Put the fabric of the planar belt on the surface-entry conveying device 1, and convey it to the pre-press surface roller 12 by the surface-entry conveyor belt 11 for preliminary pre-pressing and flattening, and then convey it to the lower conveyor belt 13 by The thinning wheel assembly 14 on the lower conveyor belt 13 is further thinned and flattened, and finally the fabric of the flat belt is rolled into a strip fabric by the rolling roller assembly 15, and the guide assembly 16 on the lower conveyor belt 13 is passed The strip fabric is conveyed to the pre-press forming device 2.

[0054] 3) Preliminary molding: the strip-shaped fabric is matched with the upper mold assembly 22 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com