Garlic inserting machine based on intermittent automatic seeding, grading, arrangement, and righting

An intermittent and seed-dropping technology, applied in potato planting machines, planting methods, agriculture, etc., can solve the problems of immature technology, difficulty in controlling the direction of garlic scales and buds, and late start of research, so as to reduce the number of holes and one hole. A variety of probabilities, conducive to widespread promotion and application, and the effect of improving the scaly tooth orientation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

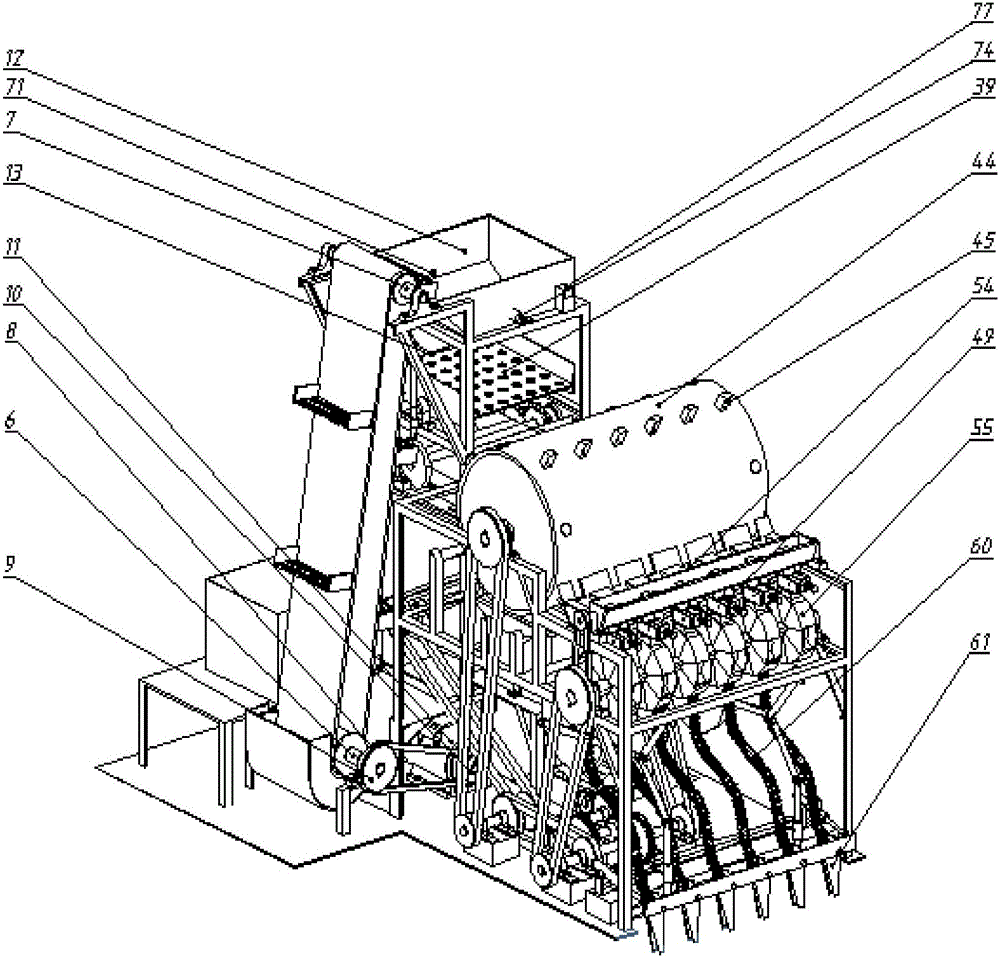

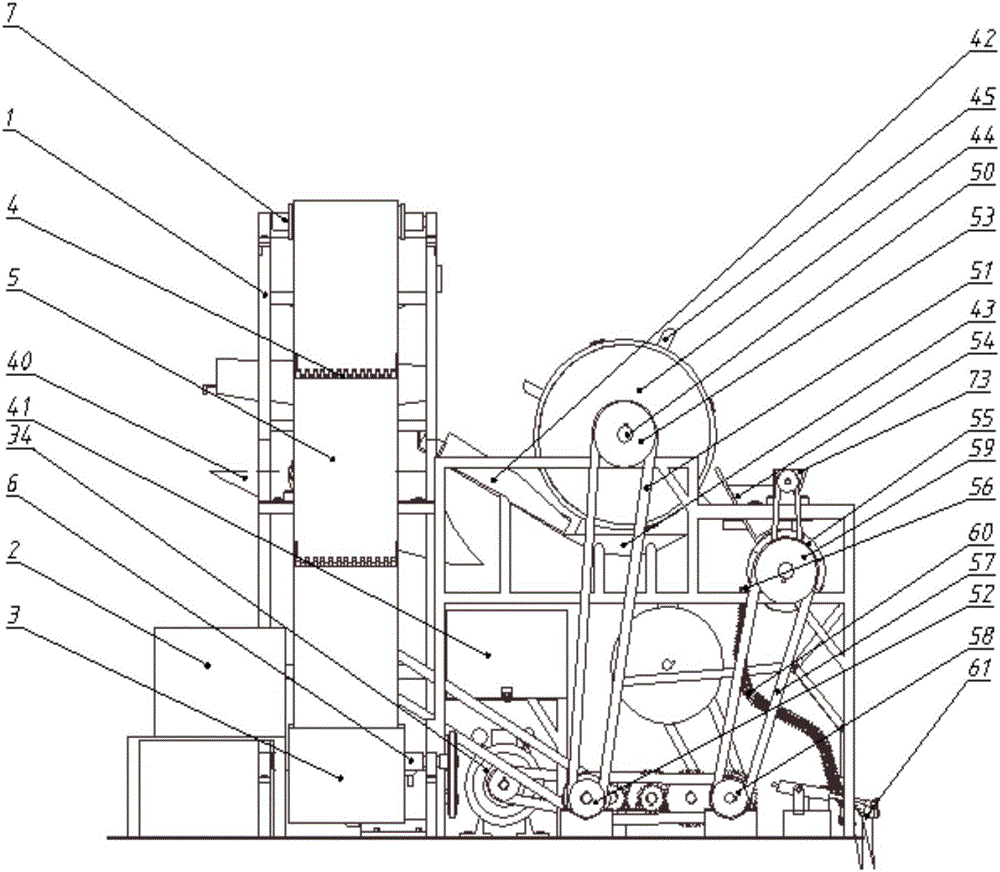

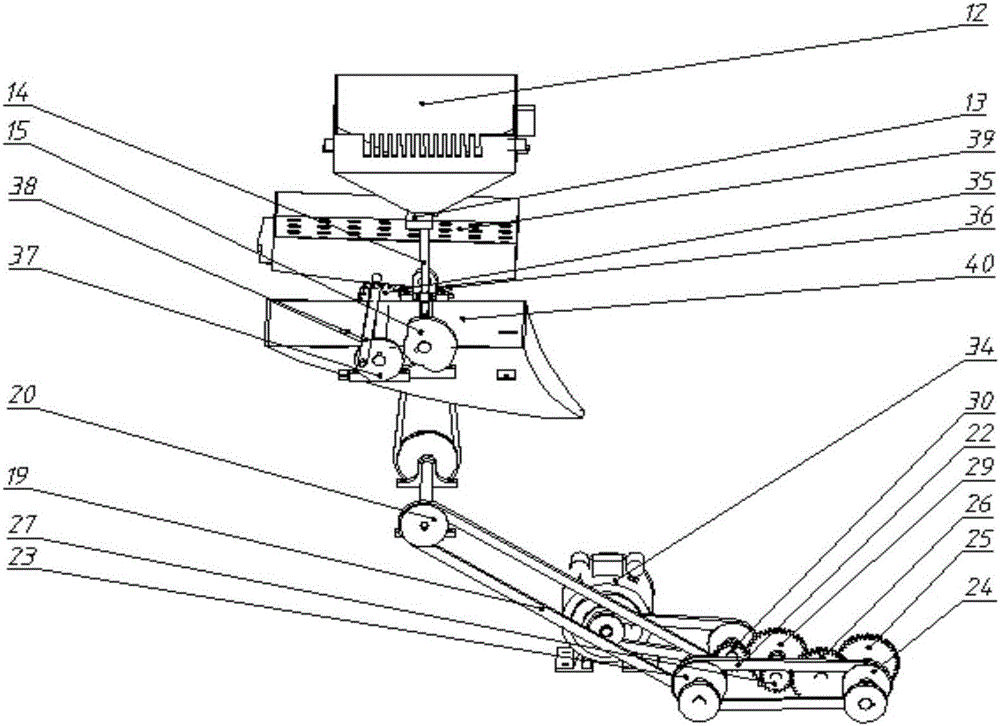

[0049] Such as figure 1 , figure 2 It is an axonometric view in two directions of the present invention, which together can more clearly show the relationship between the various components. This figure shows the positional relationship between the automatic feeding system, grading system, picking and replanting system, and righting and inserting garlic system installed on the frame 1. The automatic feeding system is driven by the auxiliary motor 11 through the belt drive to realize the automatic feeding function. .

[0050] The grading system realizes the shaking of the grading sieve and then realizes the grading of the garlic by the main motor 34 through a series of transmission systems.

[0051] The system of taking and reseeding also transmits the power of the main motor to the drum shaft 50 and the agitator 46 by the main motor 34 through a series of speed change systems such as belt drive, chain drive and gear drive to realize the function of taking and reseeding.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com