A Method for Imaging Panorama Image of Tube Reactor Furnace

A tubular reactor and panoramic image technology, which is applied in image communication, image enhancement, image data processing, etc., can solve problems such as dependence on shooting angle and feature information, large limitations, and inability to adapt to tube reactor image height similarity , to achieve the effect of reducing the amount of data processing, ensuring reliability, and improving computing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

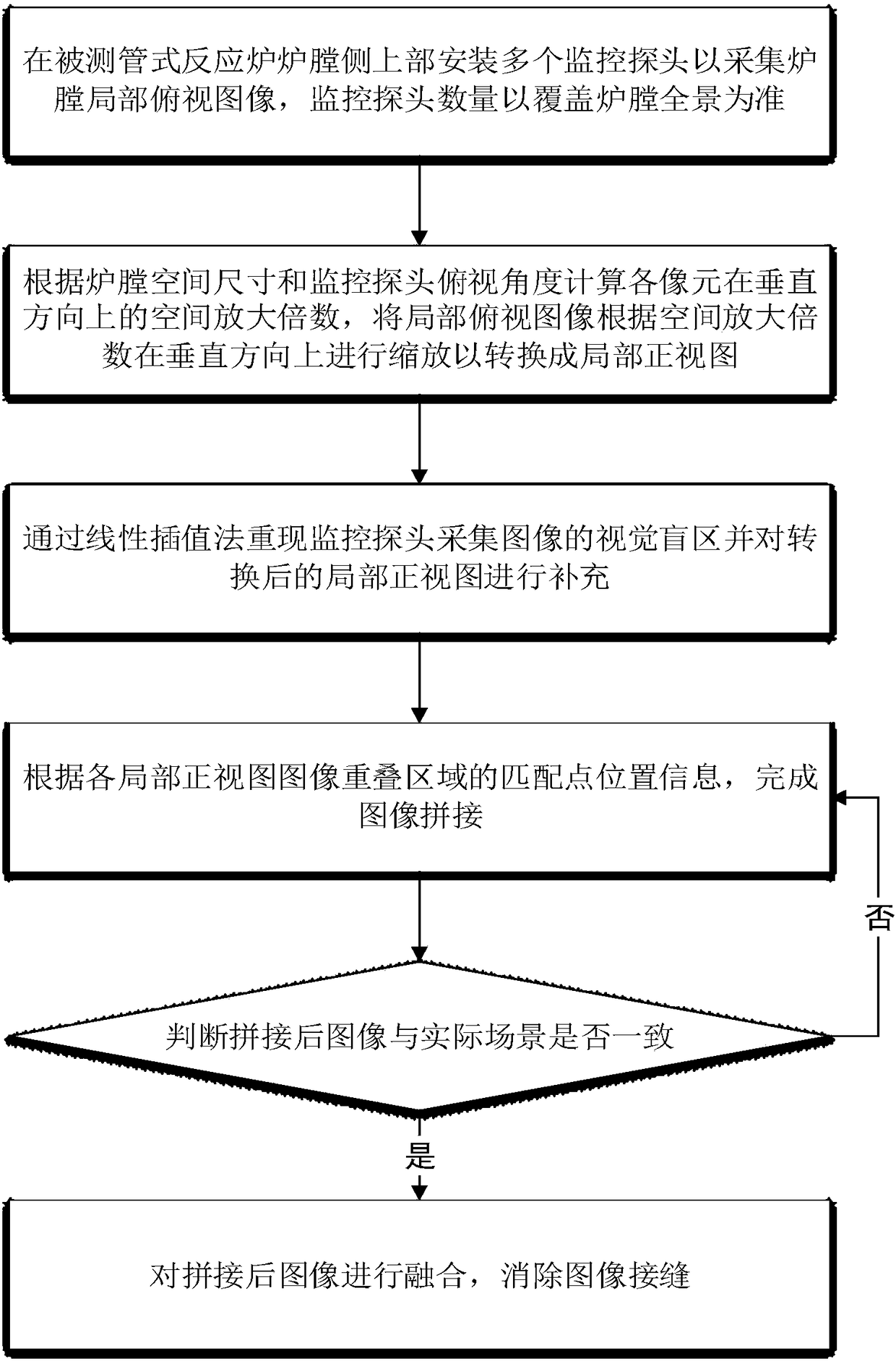

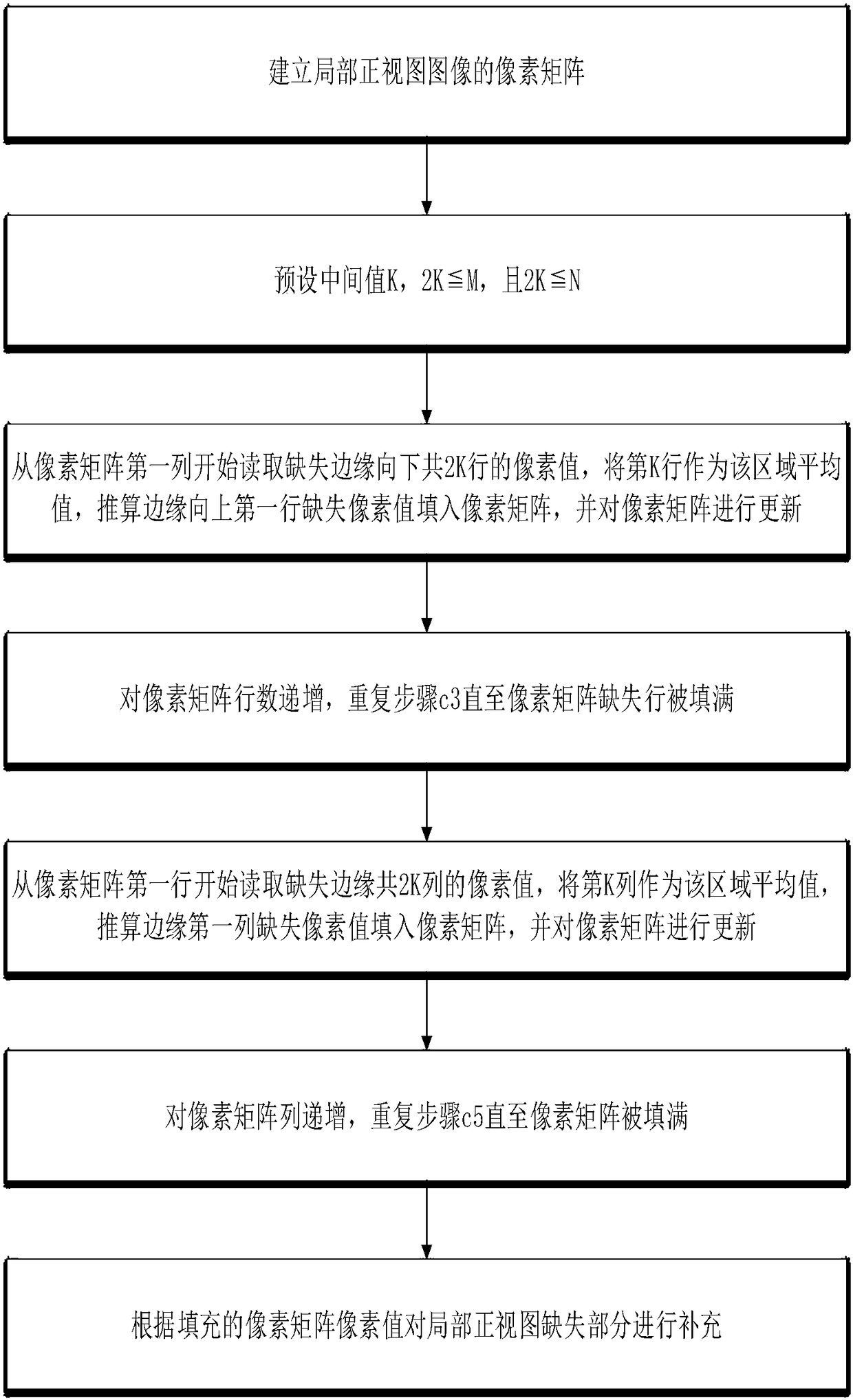

[0043] refer to figure 2 , a tubular reactor hearth panorama image imaging method proposed by the present invention includes the following steps.

[0044] a. Multiple monitoring probes are installed on the upper part of the furnace side of the tube reactor under test to collect partial overlooking images of the furnace, and the number of monitoring probes is subject to covering the panorama of the furnace.

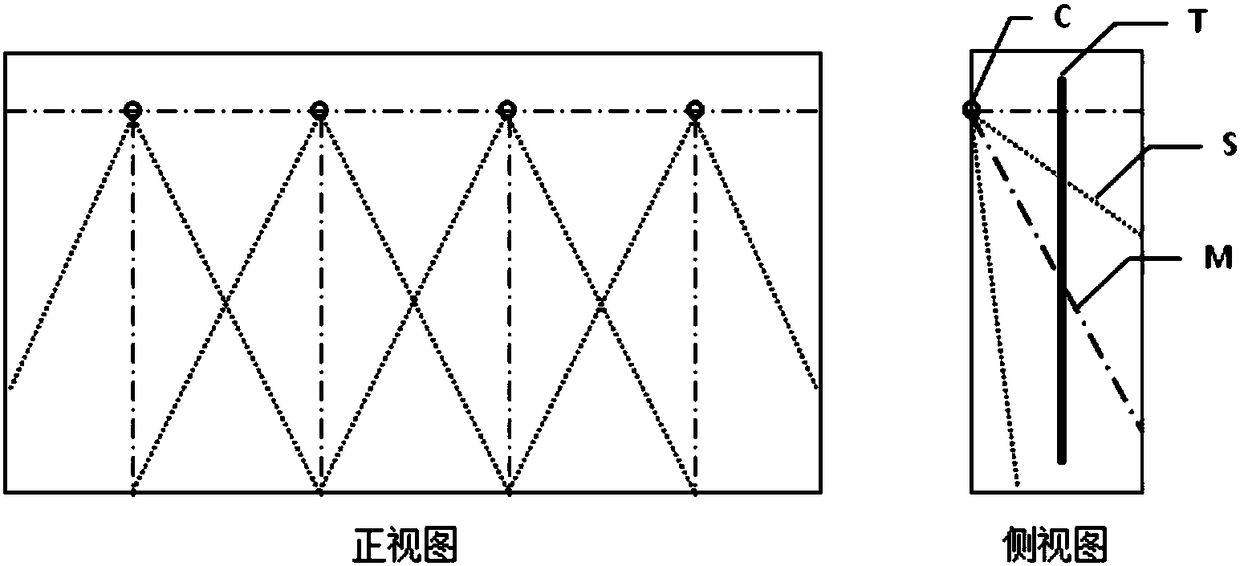

[0045] In this embodiment, the monitoring probe adopts an infrared probe, and in order to prevent the high temperature and smoke in the furnace from adversely affecting the imaging, the monitoring probe is installed in the outer protective tube, and is cooled and purged by instrument air. Specific reference figure 1 , in this embodiment, the monitoring probe is installed above the corresponding burner, and the center of the field of view of the monitoring probe is obliquely downward at a certain angle with the horizontal direction, so as to ensure that the lower edge lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com