Ring cooling machine transmission device with automatic deviation rectifying function

A technology of automatic deviation correction and transmission device, which is used in the treatment of discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of ring cooler sealing device damage, gnawing of rails, and easy deviation of the ring cooler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

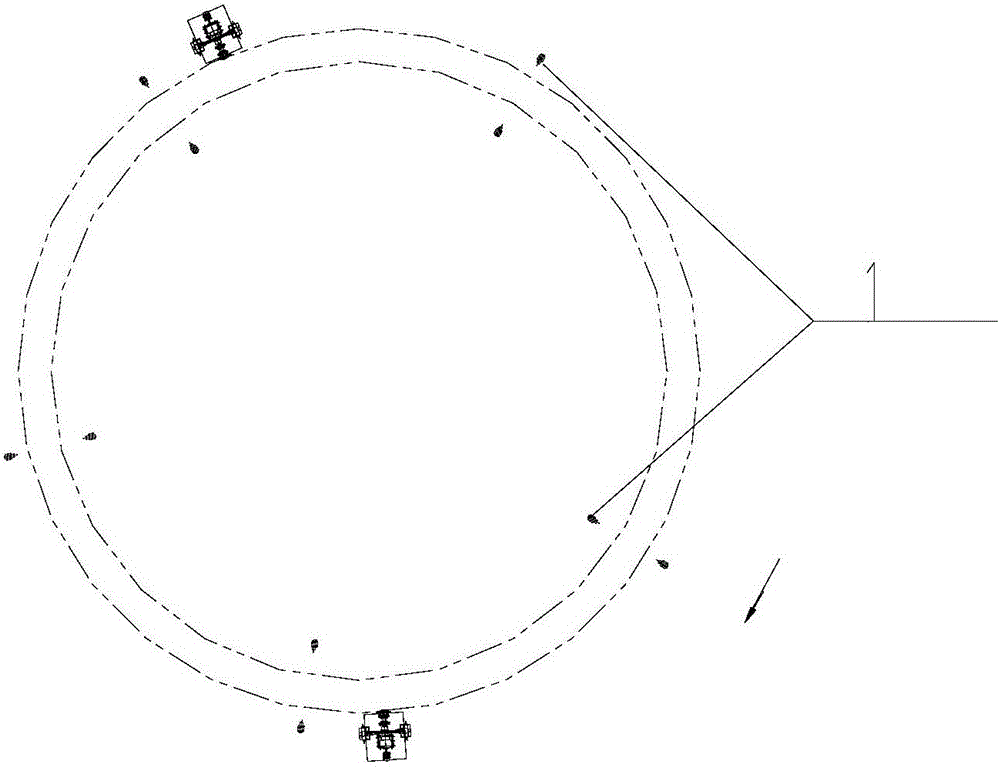

[0019] figure 1 The direction of the middle arrow indicates the running direction of the annular cooler.

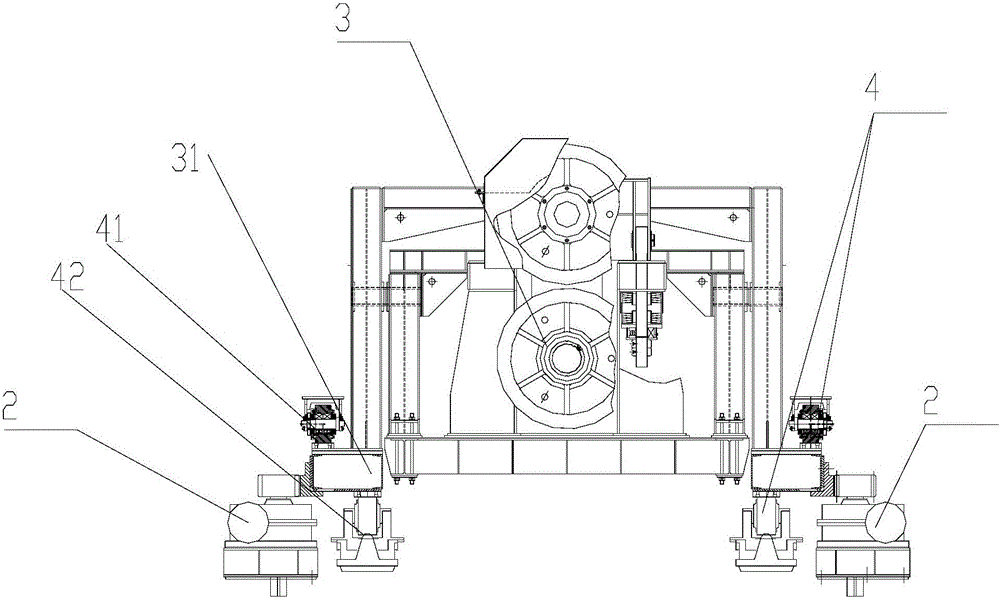

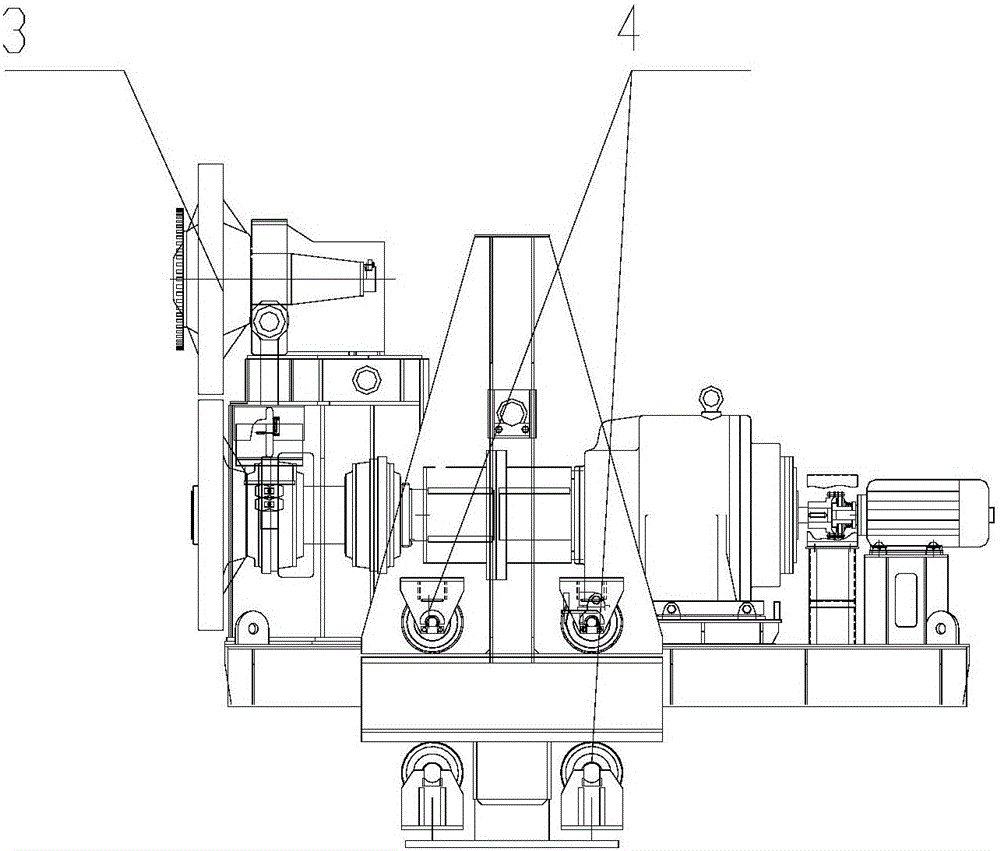

[0020] The transmission device of the annular cooler with automatic deviation correction function in this embodiment includes a measuring part 1, a steering part 2, a driving part 3 and a supporting part 4; 2 is connected with the driving part 3 and drives the driving part 3 to turn, and the steering part 2 drives the driving part after receiving the signal detected by the measuring part 1 that the frame of the rotary body of the annular cooler is deviated 3 to turn, the drive part 3 is arranged on the support part 4, and the drive part drives the rotary body frame of the annular cooler described in 3 to move.

[0021] The measuring part 1 is used to detect the deviation of the frame of the rotary body of the annular cooler, and the measuring part 1 may be a distance detector arranged symmetrically on the inner and outer sides of the frame of the rotary body of the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com