Method for determining gas content of coal bed gas reservoir

A technology of gas content and coalbed methane, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve problems such as no consideration of damage, no quantitative calculation method, etc., and achieve the effect of reliable technical support and reliable evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0032] The method for determining the gas content of a coalbed methane reservoir in the present invention comprises the following steps:

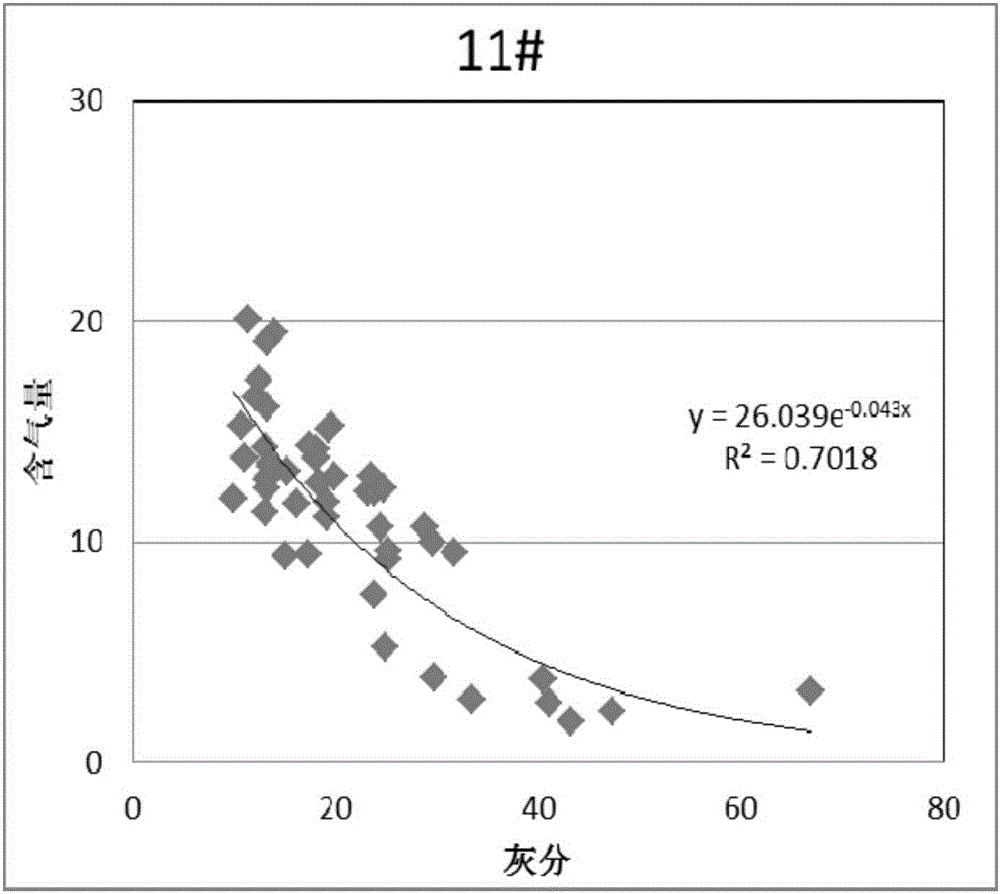

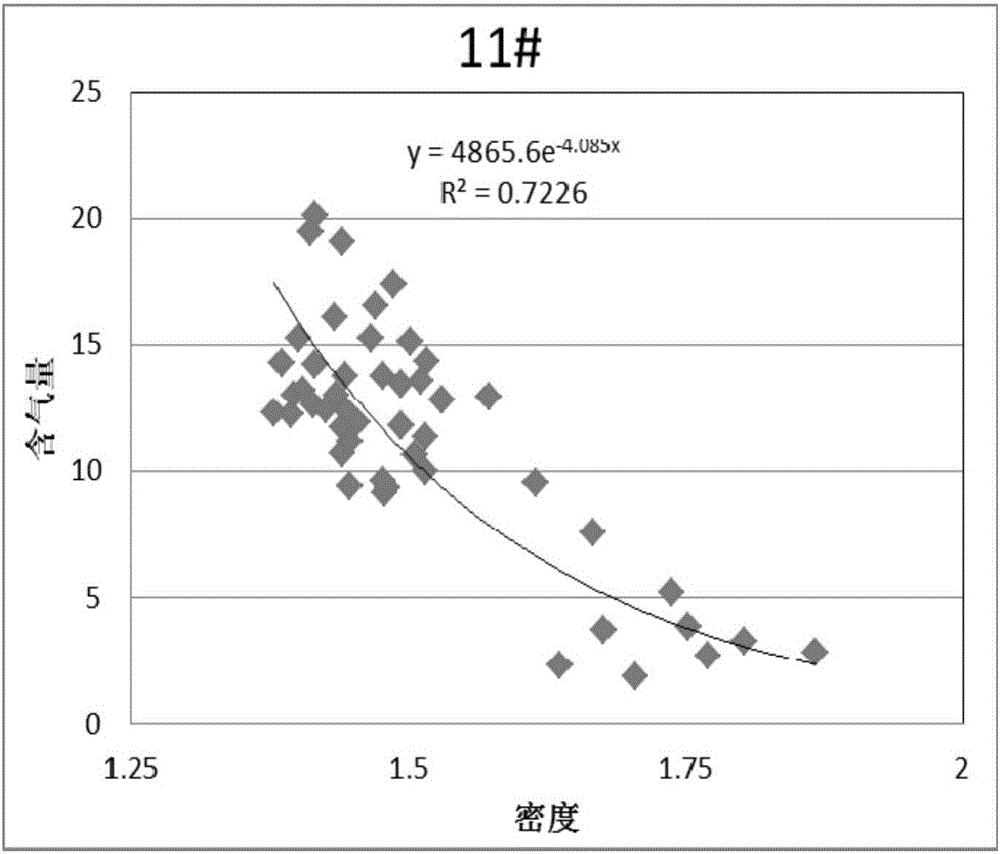

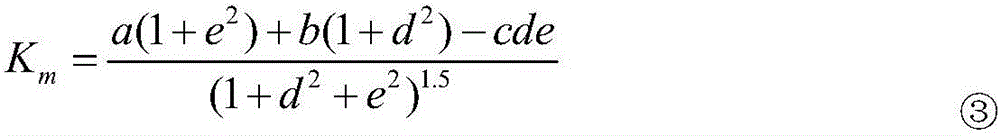

[0033] Step (1), carry out coal core gas content measurement experiment and component analysis test, carry out coal core gas content measurement according to the flow process stipulated in China United Coalbed Methane Co., Ltd. QB / MCQ1001-1999 "Coalbed Gas Content Determination Method" The coal core component determination experiment is carried out according to the process stipulated in the "China National Coal Classification Standard (GB5751-86)"; the response characteristics of the coal core gas content, coal core component data (see Table 2) and logging data determined by the experiment Establish a gas content calculation model to calculate the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com