Microfiber dyeing method and production line

A dyeing method and production line technology, applied in the field of microfiber dyeing, can solve the problems of non-recycling of dyeing solution, uneven color of products, affecting dyeing quality, etc., and achieve good color penetration effect, good dyeing effect, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

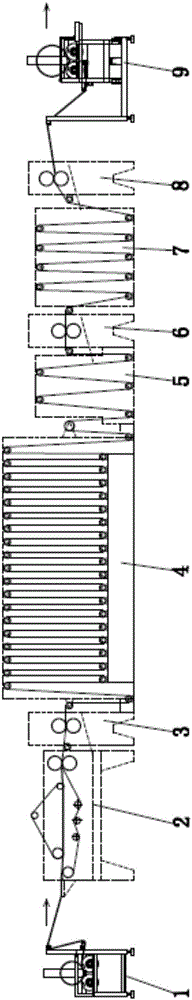

[0031] The specific implementation of this embodiment is as figure 1 As shown, a superfiber dyeing production line includes an unwinding machine 1. The output end of the unwinding machine 1 is sequentially provided with an ultrasonic dyeing machine 2, a first water squeezer 3, a steam box 4 for high temperature color fixing, a first washing machine 5, a second water squeezer 6, The second washing machine 7, the third squeezing machine 8 and the winder 9.

[0032] Taking the microfiber leather material as an example, the superfiber dyeing method is as follows:

[0033] 1) Unwinding step: put the rolled microfiber leather into the unwinder 1, and the unwinder 1 unfolds the microfiber leather;

[0034] 2) Ultrasonic dyeing step: move the microfiber leather into the ultrasonic dyeing machine 2 and place it in the dyeing solution in the ultrasonic sound field for dyeing;

[0035] 3) The first water squeezing step: the microfiber leather is squeezed by the first water squeezing m...

Embodiment 2

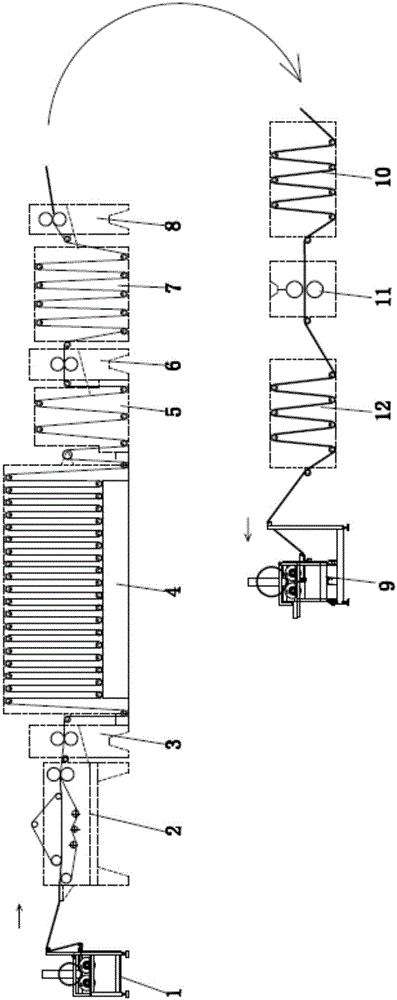

[0044] The specific implementation of this embodiment is as figure 2 As shown, a superfiber dyeing production line includes an unwinding machine 1. The output end of the unwinding machine 1 is sequentially provided with an ultrasonic dyeing machine 2, a first water squeezer 3, a steam box 4 for high temperature color fixing, a first washing machine 5, a second water squeezer 6, The second water washing machine 7 , the third water squeezer 8 , the first high temperature oven 10 , the roller coater 11 , the second high temperature oven 12 and the winder 9 .

[0045] Taking the microfiber leather material as an example, the superfiber dyeing method is as follows:

[0046] 1) Unwinding step: put the rolled microfiber leather into the unwinder 1, and the unwinder 1 unfolds the microfiber leather;

[0047] 2) Ultrasonic dyeing step: move the microfiber leather into the ultrasonic dyeing machine 2 and place it in the dyeing solution in the ultrasonic sound field for dyeing;

[0048...

Embodiment 3

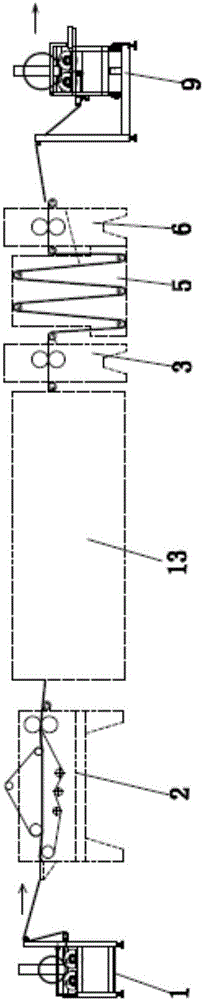

[0060] The specific implementation of this embodiment is as image 3 As shown, the output end of the unwinding machine 1 is provided with an ultrasonic dyeing machine 2, a low-temperature chemical color fixing machine 13 and a winding machine 9 in sequence along the direction of the production line.

[0061] Taking the microfiber leather material as an example, the superfiber dyeing method is as follows:

[0062] 1) Unwinding step: put the rolled microfiber leather into the unwinder 1, and the unwinder 1 unfolds the microfiber leather;

[0063] 2) Ultrasonic dyeing step: move the microfiber leather into the ultrasonic dyeing machine 2 and place it in the dyeing solution in the ultrasonic sound field for dyeing;

[0064] 3) Low-temperature chemical color-fixing step: move the microfiber leather to the low-temperature chemical color-fixing machine 13, and the low-temperature chemical color-fixing machine 13 sprays a chemical agent on it to achieve the purpose of color fixing; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com