EVA composite adhesive film used for photovoltaic packaging and having anti-PID performance

A composite adhesive, photovoltaic technology, applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve the problems of photovoltaic module products failing to pass PID test, battery power reduction, etc., to achieve good PID performance , the effect of improving service life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

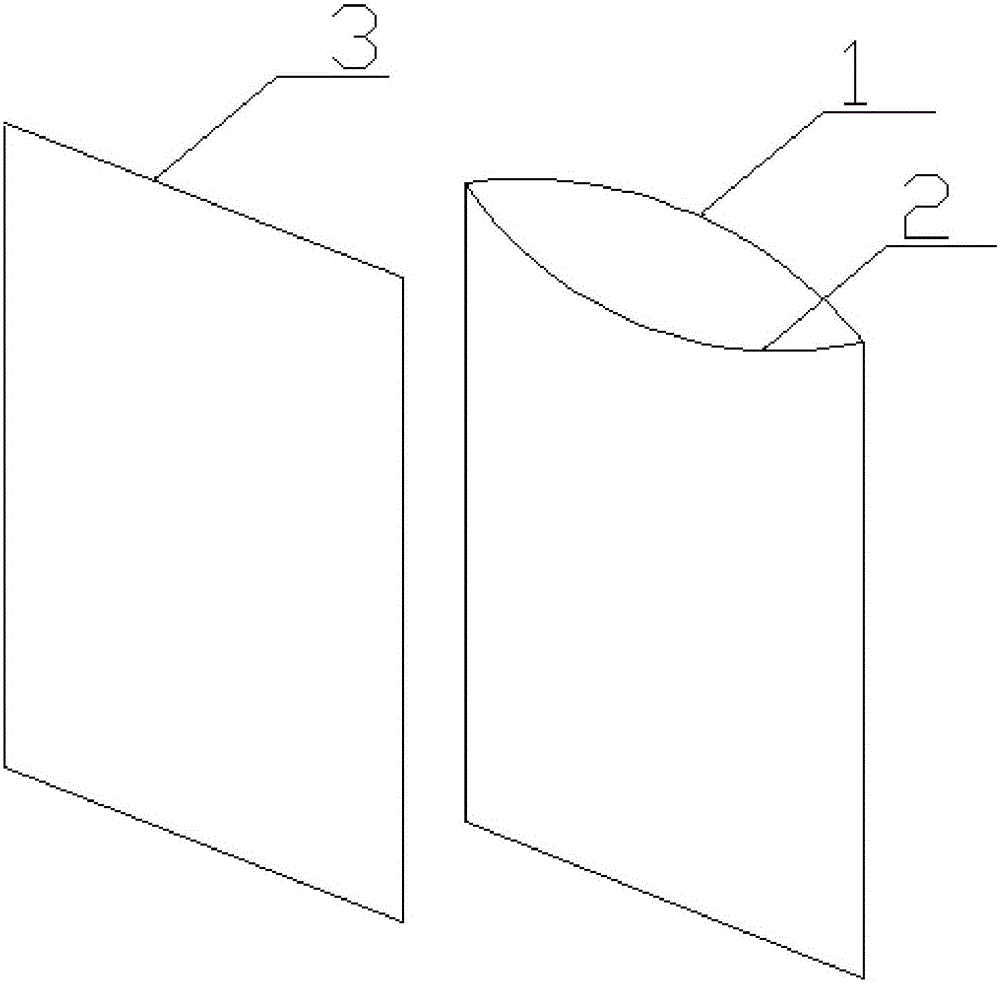

[0045] combined with figure 1 As shown, the present embodiment provides a kind of EVA composite adhesive film with anti-PID performance for photovoltaic encapsulation, which comprises an anti-ultraviolet EVA adhesive film layer 1, a transparent EVA adhesive film layer 2 and a white reflective EVA adhesive film layer 3 successively, wherein, The transparent EVA film layer 2 and the side of the reflective EVA film layer 3 are fixed to form a bag-shaped structure with one side opening, the solar cells are placed in the bag-shaped structure, and the ultraviolet-proof EVA film layer 1 is arranged on the front side of the battery sheet; the surface of the transparent EVA film layer 2 opposite to the reflective EVA film layer 3 is provided with patterns.

[0046]Wherein, the VA content of the anti-ultraviolet EVA film layer is 20%, the VA content of the transparent EVA film layer is 22%, and the VA content of the white reflective EVA film layer is 24%.

[0047] The thicknesses of th...

Embodiment 2

[0062] combined with figure 1 As shown, the present embodiment provides a kind of EVA composite adhesive film for photovoltaic encapsulation with anti-PID performance, it comprises anti-ultraviolet EVA adhesive film layer 1, transparent EVA adhesive film layer 2 and white reflective EVA adhesive film layer 3 successively, wherein, The transparent EVA film layer 2 and the side of the white reflective EVA film layer 3 are fixed to form a bag-like structure with one side opening, the solar cells are placed in the bag-like structure, and the ultraviolet-proof EVA film Layer 1 is arranged on the front side of the battery sheet; the surface of the transparent EVA film layer 2 opposite to the white reflective EVA film layer 3 is provided with patterns.

[0063] Wherein, the VA content of the anti-ultraviolet EVA film layer is 22%, the VA content of the transparent EVA film layer is 24%, and the VA content of the white reflective EVA film layer is 26%.

[0064] The thicknesses of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com