Historical-building protective material

A technology for protective materials and ancient buildings, applied in the direction of fireproof coatings, antifouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of cultural relics damage, inability to be waterproof, and poor fireproofing effect, and achieve strong fireproofing and Water resistance, extended life and storage time, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

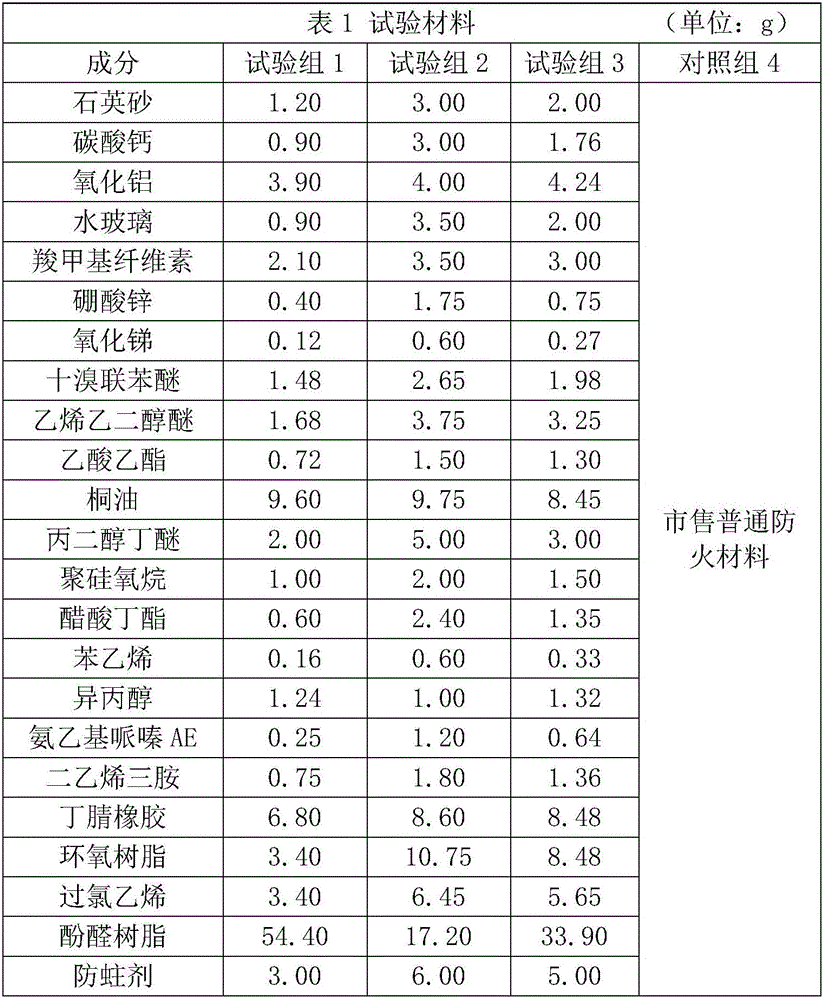

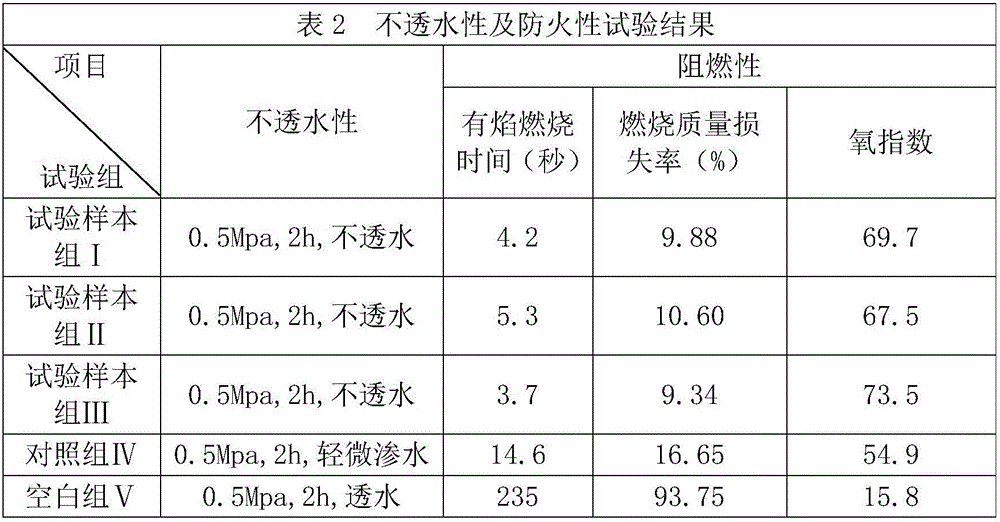

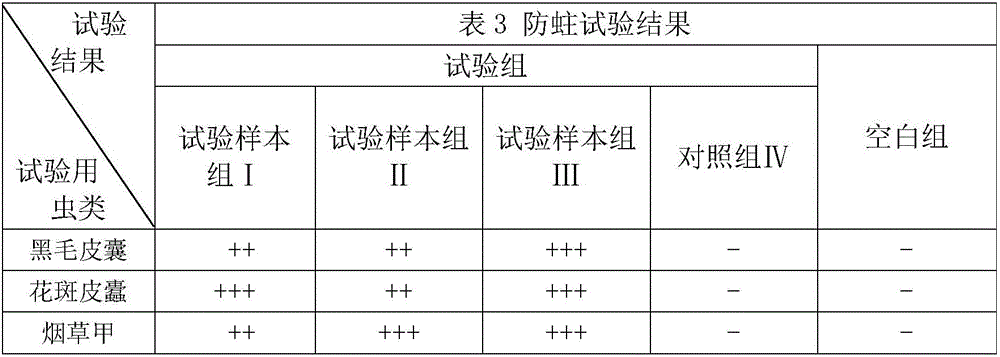

[0016] Embodiment 1, a kind of historical ancient building protective material, calculated by weight percentage, consists of 6% refractory minerals, 3% adhesive, 2% flame retardant fireproof additive, 12% organic solvent, 2% synthetic Membrane auxiliary agent, 1% water-repellent agent, 2% diluent, 1% curing agent, 3% anti-moth agent and the remaining flame retardant resin composition, described film-forming auxiliary agent is propylene glycol butyl ether, so The water-repellent agent is polysiloxane powder, and the anti-moth agent is the extract of camphor leaves, mugwort leaves and yamba leaves.

[0017] Calculated by weight percentage:

[0018] The refractory mineral is composed of 20% quartz sand, 15% calcium carbonate and 65% alumina; the binder is composed of 30% water glass and 70% carboxymethyl cellulose; the refractory The flame retardant additive is composed of 20% zinc borate, 6% antimony oxide and 74% decabromodiphenyl ether; the flame retardant resin is composed o...

Embodiment 2

[0019] Embodiment 2, a kind of historical ancient building protective material, calculated by weight percentage, consists of 10% refractory minerals, 7% adhesive, 5% flame retardant fireproof additive, 15% organic solvent, 5% synthetic Membrane auxiliary agent, 2% water-repellent agent, 4% diluent, 3% curing agent, 6% anti-moth agent and the remaining flame retardant resin composition, described film-forming auxiliary agent is propylene glycol butyl ether, so The water-repellent agent is polysiloxane powder, and the anti-moth agent is the extract of camphor leaves, mugwort leaves and yamba leaves.

[0020] Calculated by weight percentage:

[0021] The refractory mineral is composed of 30% quartz sand, 30% calcium carbonate and 40% alumina; the binder is composed of 50% water glass and 50% carboxymethyl cellulose; the refractory The flame retardant additive is composed of 35% zinc borate, 12% antimony oxide and 53% decabromodiphenyl ether; the flame retardant resin is composed...

Embodiment 3

[0022] Embodiment 3, a kind of historical ancient building protection material, by weight percentage, by 8% refractory mineral matter, 5% adhesive, 3% flame retardant fireproof additive, 13% organic solvent, 3% synthetic Membrane aid, 1.5% water-repellent agent, 3% diluent, 2% curing agent, 5% anti-moth agent and the remaining flame retardant resin composition, described film-forming aid is propylene glycol butyl ether, so The water-repellent agent is polysiloxane powder, and the anti-moth agent is the extract of camphor leaves, mugwort leaves and yamba leaves.

[0023] Calculated by weight percentage:

[0024] The refractory mineral is composed of 25% quartz sand, 22% calcium carbonate and 53% alumina; the binder is composed of 40% water glass and 60% carboxymethyl cellulose; the refractory The flame retardant additive is composed of 25% zinc borate, 9% antimony oxide and 66% decabromodiphenyl ether; the flame retardant resin is composed of 15% nitrile rubber, 15% epoxy resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com