Sand wall like coating containing water-based dyeing colored sand and preparation method of sand wall like coating

A sand wall-like coating and water-based technology, which is applied to the sand wall-like coating containing water-based dyed colored sand and its preparation field, can solve the problems of poor water resistance, chemical resistance and comprehensive adhesion performance, potential compatibility risks, and unstable products, etc. problem, to achieve the effect of good wear resistance, shortened production and color matching time, uniform and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A water-based dyed colored sand, the raw material formula is water-based composite dyeing agent: quartz sand is 120:1000 (mass ratio).

[0040] The preparation steps of the water-based dyed colored sand are:

[0041] A. Put 10-20 mesh, 20-40 mesh, 40-80 mesh, 80-120 mesh quartz sand into the mixer at a ratio of 1:1:1:1, and spray into the formula at a speed of 100 rpm Amount of water-based composite dyeing agent, stir for 10 minutes after spraying.

[0042] B. Pour the above-mentioned uniformly stirred mixture into a rotary dryer, and control the temperature to dry at 80°C for 20 minutes.

[0043] C. Sieve and classify the drying material according to 10-20 mesh, 20-40 mesh, 40-80 mesh, and above 80 mesh to obtain water-based dyed colored sand with different particle sizes.

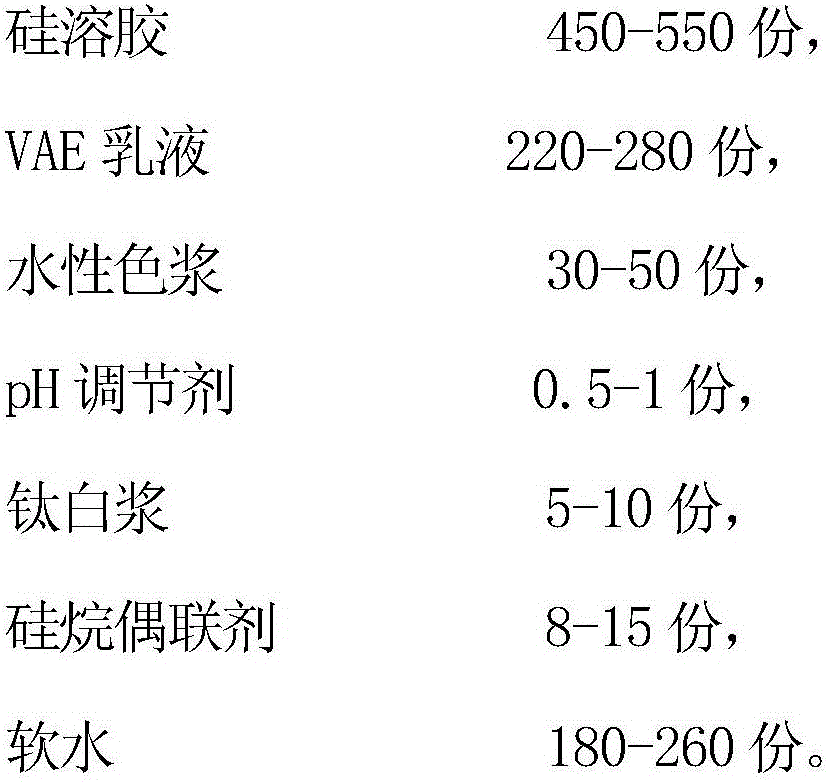

[0044] The raw material formula of water-based composite dyeing agent is (mass parts):

[0045]

[0046]

[0047] The preparation steps of composite dyeing agent are:

[0048]1) VAE emuls...

Embodiment 2

[0054] The raw material formula of sand wall shape architectural paint is as follows (mass parts):

[0055]

[0056] The preparation steps of described sand wall shape architectural paint are:

[0057] Add (260KG) basic slurry into the reaction kettle, start stirring, put in various water-based dyed colored sands (740KG) at a stirring speed of 100 rpm, control the input speed, and finish throwing in 30 minutes to prevent the dyed colored sands from agglomerating After adding, continue to stir for 30 minutes to obtain sand wall-like coating.

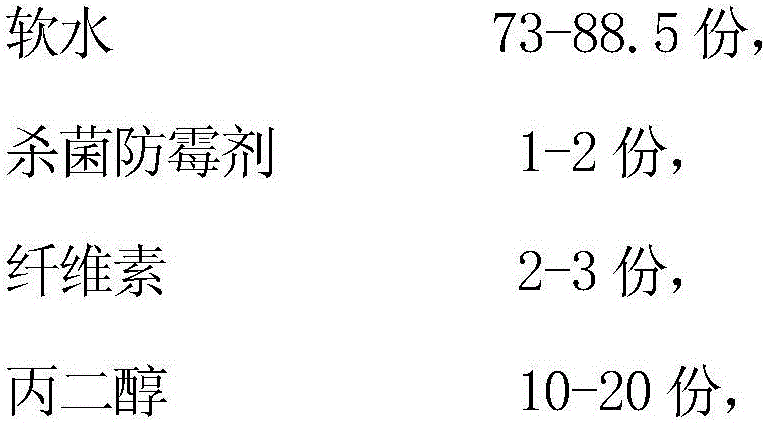

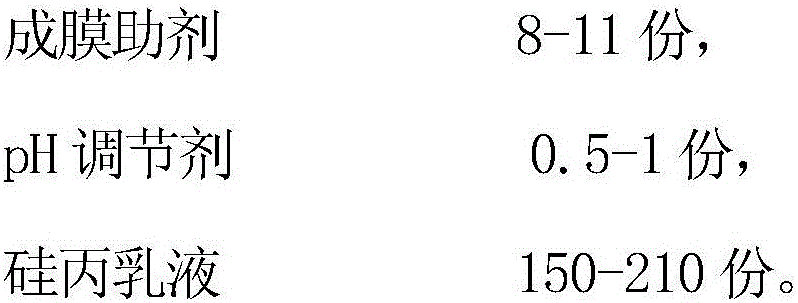

[0058] Among them, the basic slurry raw material formula:

[0059]

[0060] The preparation steps of basic slurry are:

[0061] A. Add 88.5KG of soft water into the reactor, put in cellulose HBR250 (2KG) at a speed of 700 rpm, and disperse for 15 minutes.

[0062] B. Add bactericidal antifungal agent (WL-3), propylene glycol, film-forming aid, pH regulator at a speed of 700 rpm, and disperse for 10 minutes, then add silicon acryl...

Embodiment 3

[0067] The formula raw material of sand wall shape architectural paint is as follows (mass parts):

[0068]

[0069] The preparation steps of described sand wall shape architectural paint are as follows:

[0070] Add (320KG) basic slurry into the reaction kettle, start stirring, and put in various water-based dyed colored sands (680KG) at a stirring speed of 100 rpm. Continue stirring for 30 minutes after adding to obtain a sand wall-like coating.

[0071] Among them, the basic slurry raw material formula:

[0072]

[0073]

[0074] The preparation steps of basic slurry are:

[0075] A. Add 73KG of soft water into the reactor, put in cellulose HBR250 (3KG) at a speed of 700 rpm, and disperse for 15 minutes.

[0076] B. Add bactericidal antifungal agent (WL-3), propylene glycol, film-forming aid, pH regulator at a speed of 700 rpm, and disperse for 10 minutes, then add silicon acrylic emulsion (996AD) at 500 rpm Stir evenly to prepare the basic slurry.

[0077] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com