Carbon fiber reinforced nylon composite draw-bar box castor

A trolley case and carbon fiber technology, applied in the field of carbon fiber reinforced nylon composite trolley case casters, can solve the problems of low surface finish, high cost, poor processability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

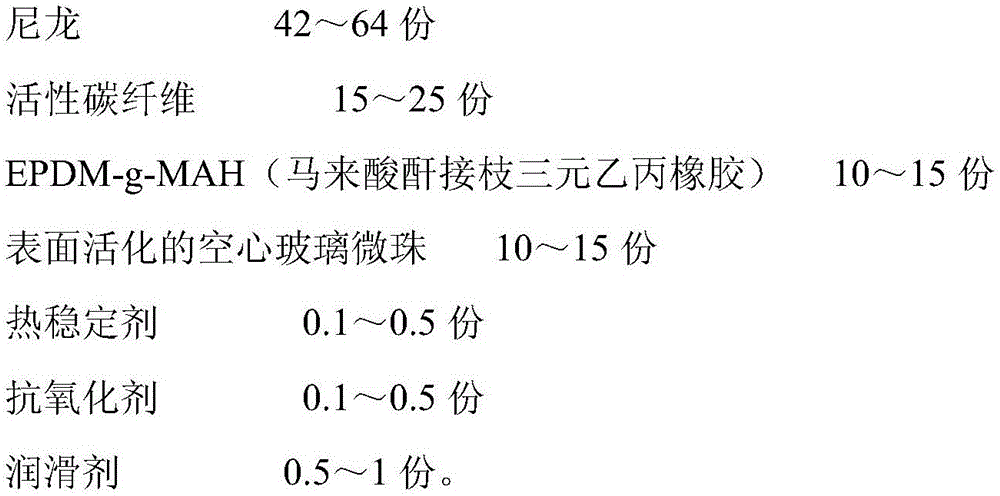

[0041] A carbon fiber reinforced nylon composite trolley case caster, comprising the following components by weight:

[0042]

[0043] The EPDM-g-MAH has a high grafting rate of 1.6% and a grafting efficiency of 80%.

[0044] Calcium stearate, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, stearic acid and dried nylon 66, EPDM-g-MAH, surface activation The hollow glass microspheres are mixed in a high-speed mixer to obtain a mixture; the mixture and short active carbon fibers are granulated and then injection molded to obtain trolley case casters.

Embodiment 2

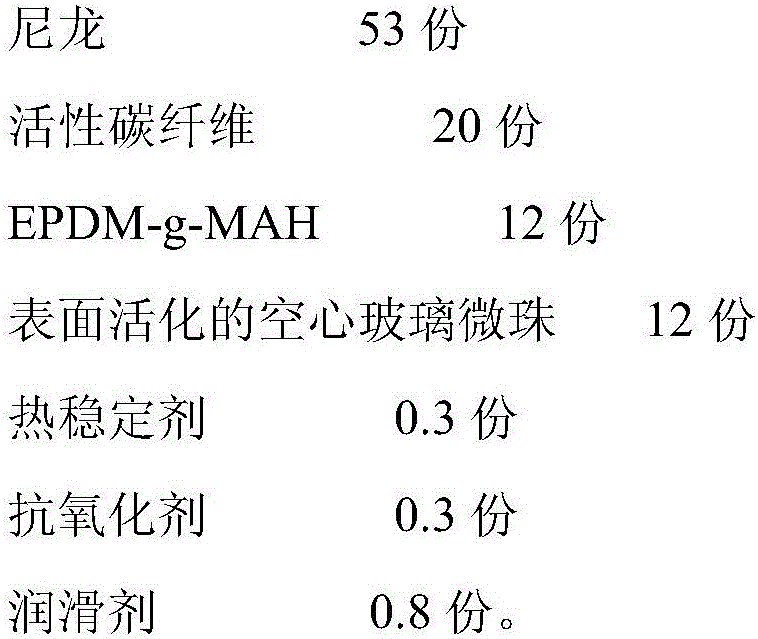

[0046] A carbon fiber reinforced nylon composite trolley case caster, comprising the following components by weight:

[0047]

[0048] The EPDM-g-MAH has a high grafting rate of 1.6% and a grafting efficiency of 80%.

[0049] Magnesium stearate, tris(2,4-di-tert-butylphenyl) phosphite, polyethylene wax, dried nylon 6, EPDM-g-MAH, and surface-activated hollow glass microspheres were mixed in a high-speed mixer Mix in medium to obtain a mixture; pelletize the mixture and active short carbon fibers and then injection mold to obtain trolley case casters.

Embodiment 3

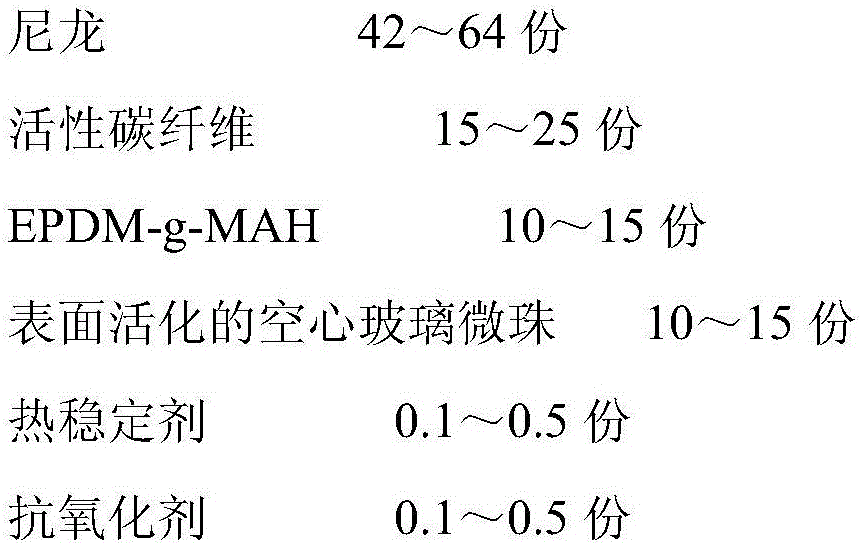

[0051] A carbon fiber reinforced nylon composite trolley case caster, comprising the following components by weight:

[0052]

[0053]The EPDM-g-MAH has a high grafting rate of 1.6% and a grafting efficiency of 80%.

[0054] Magnesium stearate, tris(2,4-di-tert-butylphenyl) phosphite, polyethylene wax, dried nylon 6, EPDM-g-MAH, and surface-activated hollow glass microspheres were mixed in a high-speed mixer and mixing in a medium to obtain a mixture; the mixture and activated carbon fibers are granulated and then injection molded to obtain trolley case casters.

[0055] The performance comparison table of the trolley case caster material of each embodiment of table 1

[0056]

[0057]

[0058] Abrasion: Test according to GB3960-1983 standard, apply 20 kg force, 45 # Steel pair grinding ring, time 2 hours.

[0059] As can be seen from Table 1, the performance of each inspection item of the trolley case caster material of each embodiment of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com