Processing method for establishing anticorrosion system in acidic silica sol

A technology of acidic silica sol and treatment method, which is applied in the direction of chemical instruments and methods, silicon compounds, polishing compositions containing abrasives, etc., can solve the problems of easy deterioration, achieve low cost, prevent deterioration, and solve the problem of easy odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare 1 kg of polishing solution from the deteriorated acidic silica sol.

[0023] This 1 kg of polishing solution was heated to 65° C., kept stirring during the heating process, and cooled to room temperature after heating, and methylisothiazolinone (MIT) was used as a bactericide.

[0024] Two treatments are available:

[0025] 1. One-time treatment: process the cooled polishing solution in the process of continuous stirring, take the antiseptic and bactericide, add the antiseptic and bactericide to the polishing solution with stirring, and the quality of the added antiseptic and bactericide is in the system 0.3% of the total mass of the solution, the stirring time is 10 minutes, and the treatment is completed after the stirring is completed.

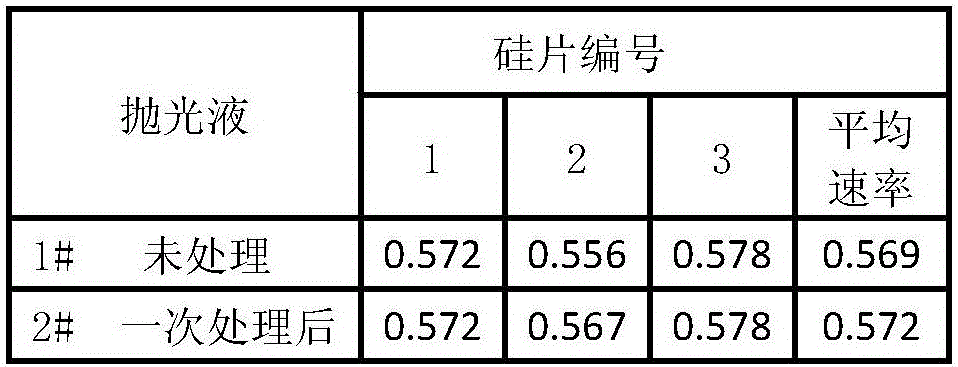

[0026] Experimental effect analysis: The silica sol after the above treatment has no change in its pH value, specific gravity, viscosity and other parameters, and the treated silica sol is used to prepare polishing liquid, a...

Embodiment 2

[0034] Prepare 1 kg of polishing solution from the deteriorated acidic silica sol.

[0035] Heat this 1 kg of polishing solution to 80° C., keep stirring during the heating process, cool to room temperature after heating, and select dichlorophen bactericide for use.

[0036] Two treatments are available:

[0037] 1. One-time treatment: process the cooled polishing solution in the process of continuous stirring, take the antiseptic and bactericide, add the antiseptic and bactericide to the polishing solution with stirring, and the quality of the added antiseptic and bactericide is in the system 0.5% of the total mass of the solution, the stirring time is 6 minutes, after the stirring is completed, the treatment is completed.

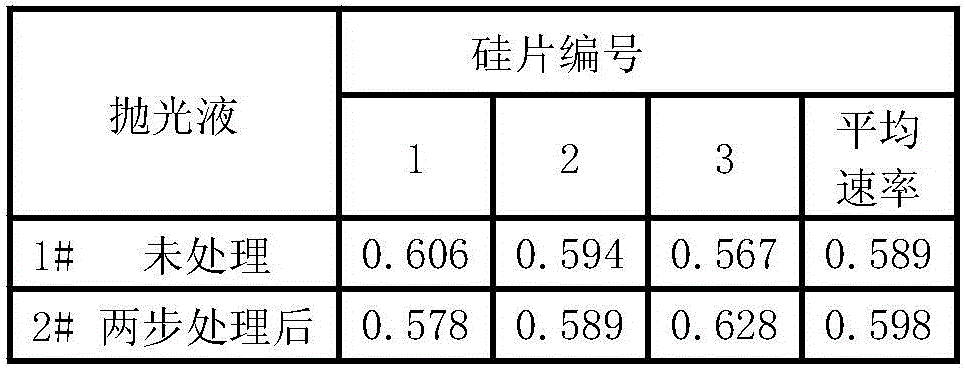

[0038] Experimental effect analysis: The silica sol after the above treatment has no change in its pH value, specific gravity, viscosity and other parameters, and the treated silica sol is used to prepare polishing liquid, and the silica sol is processed...

Embodiment 3

[0046] Prepare 1 kg of polishing solution from the deteriorated acidic silica sol.

[0047] Heat this 1 kg of polishing solution to 80° C., keep stirring during the heating process, cool to room temperature after heating, and select benzalkonium chloride as the bactericide.

[0048] Two treatments are available:

[0049] 1. One-time treatment: process the cooled polishing solution in the process of continuous stirring, take the antiseptic and bactericide, add the antiseptic and bactericide to the polishing solution with stirring, and the quality of the added antiseptic and bactericide is in the system 0.01% of the total mass of the solution, the stirring time is 3 minutes, and the treatment is completed after the stirring is completed.

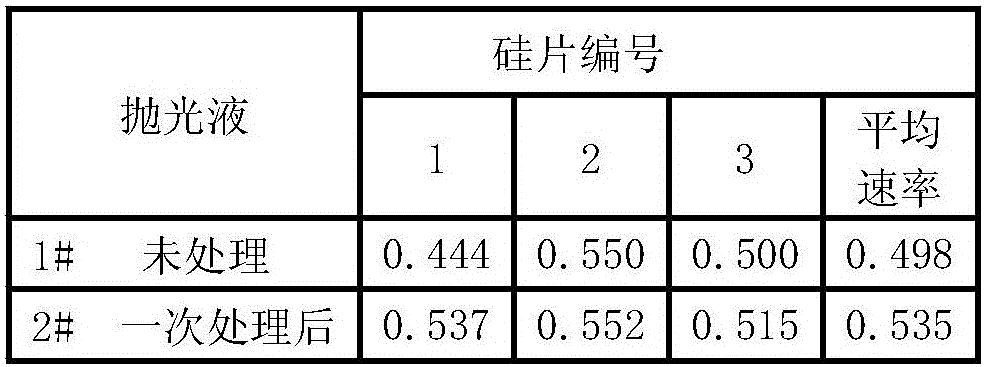

[0050] Experimental effect analysis: The silica sol after the above treatment has no change in its pH value, specific gravity, viscosity and other parameters, and the treated silica sol is used to prepare polishing liquid, and the silica sol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com