A kind of preparation method of high tap density spherical silver powder

A technology of tap density and spherical shape, applied in the field of preparation of spherical silver powder, can solve problems such as difficult control of production conditions, and achieve the effects of safe and environmentally friendly production process, narrow particle size dispersion range and high sphericity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

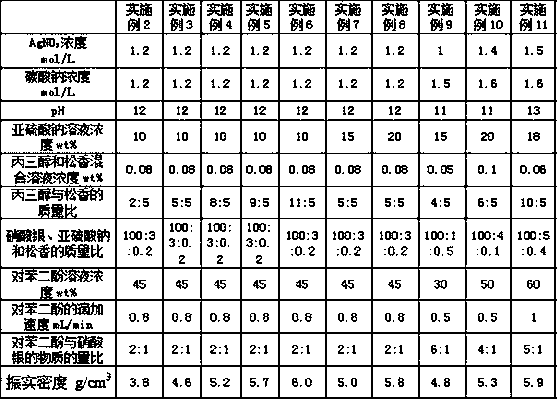

Examples

Embodiment 1

[0028] A kind of preparation method of the spherical silver powder of high tap density, comprises the following steps:

[0029] (1) Prepare silver nitrate solution with deionized water, the concentration of silver nitrate in the solution is 1.2 mol / L;

[0030] (2) Add dropwise a sodium carbonate solution with a concentration of 1.2mol / L to the silver nitrate solution prepared in step (1), adjust the pH to 12, and stir at a speed of 80 r / min;

[0031] (3) Dissolve sodium sulfite crystals with deionized water, stir until completely dissolved, and prepare a sodium sulfite solution with a mass fraction of 10%;

[0032] (4) Dissolve rosin directly with ethanol, stir and dissolve completely, then add glycerin to obtain a mixed solution with a mass fraction of glycerol and rosin of 0.08%, wherein the mass ratio of glycerol to rosin is 1:5;

[0033] (5) Add the sodium sulfite solution in step (3) and the mixed solution in step (4) to the solution in step (2) at the same time, stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com