Carbon-based material, preparation method thereof and purpose thereof

A technology of carbon-based materials and raw materials, applied in the field of oxygen-containing carbon-based materials and their preparation, to achieve the effect of improving conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

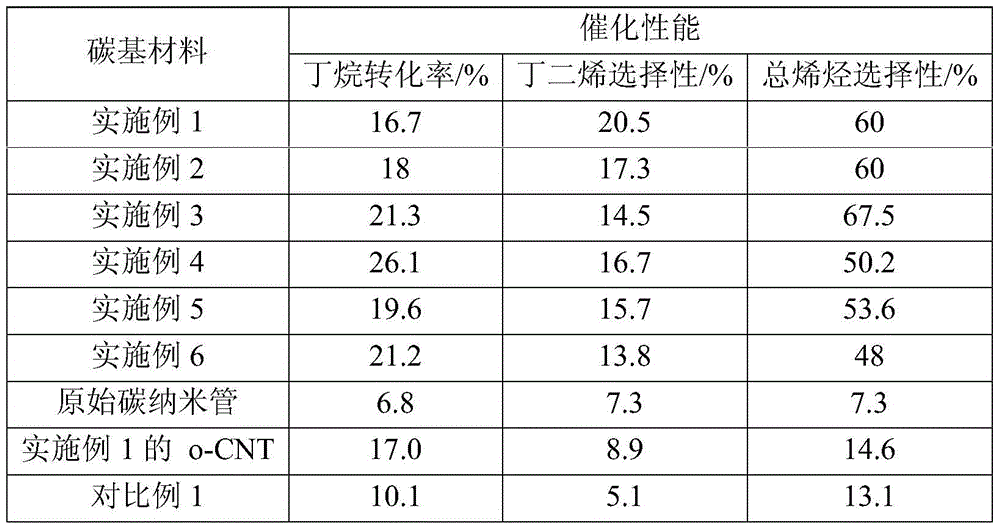

Examples

Embodiment approach

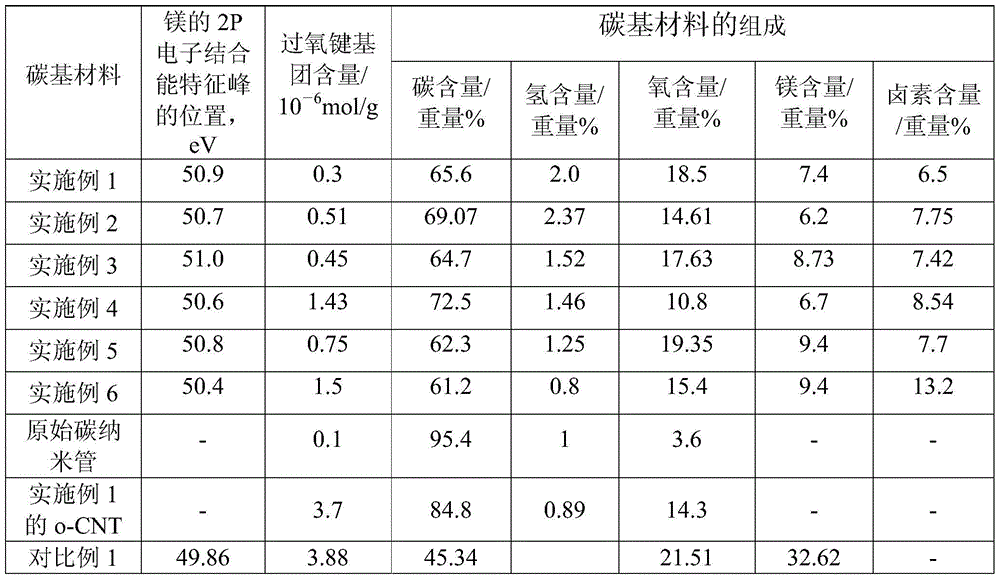

[0027] In the method for preparing a carbon-based material provided by the present invention, in the step (1), the raw material of the carbon-based material is contacted with a Grignard reagent in an inert atmosphere to treat the raw material of the carbon-based material. The carbon-based material raw material (also referred to as a solid carbon source in the present invention) contains oxygen, for example, the content of oxygen in the carbon-based material raw material can be 5-40% by weight, such as 5-35% by weight, 5- 30% by weight, preferably 5-25% by weight, more preferably 5-20% by weight. One embodiment, the peroxy group content in the carbon-based material raw material is not less than 0.5×10 -6 mol / g, for example 0.5×10 -6 mol / g~500×10 -6 mol / g, 2.5×10 -6 mol / g~50×10 -6mol / g or 3×10 -6 mol / g~10×10 -6 mol / g, for example, it can be greater than 1×10 -6 mol / g or not less than 2×10 -6 mol / g.

[0028] The carbon-based material raw material (also referred to as a s...

Embodiment 1

[0047] (1) Add 10g of carbon nanotubes to 500mL of mixed acid (V 硫酸 :V 硝酸 =3), then place the beaker in an ultrasonic cleaner, and after ultrasonication for 10 h, wash with deionized water until the filtrate is neutral. Finally, put the filter cake in an oven at 120°C and dry for 12 hours to obtain carbon nanotubes (o-CNTs) with an oxygen content of about 14% by mass.

[0048] (2) According to the ratio of adding 20mL of 1.0M phenylmagnesium chloride ether solution to 1go-CNT, mix o-CNT and phenylmagnesium chloride ether solution, stir at room temperature (for example, 25°C) for 2h, reflux at 1atm boiling point for 12h, and wash with ether for 4 ~5 times, and dried at 80° C. for 2 hours to obtain the carbon-based material provided by the present invention. The carbon-based material has a carbon nanotube structure, and its composition, peroxide group content, and characteristic peak characterization results of 2P electron binding energy of magnesium are shown in Table 1.

Embodiment 2

[0050] It is the same as step (2) of Example 1, except that in step (2), activated carbon with an oxygen content of 9.53% by weight is used to replace the o-CNT. The obtained carbon-based material is an activated carbon structure, and its composition, peroxide group content, and characteristic peak characterization results of 2P electron binding energy of magnesium are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com