Nail polish with sequins, laser powder and rhinestone powder

A technology of man-made diamond powder and laser powder, which is applied in the field of finger color with laser powder, glitter flakes, and man-made diamond powder, which can solve problems such as pollution, dry nails, and brittle nails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

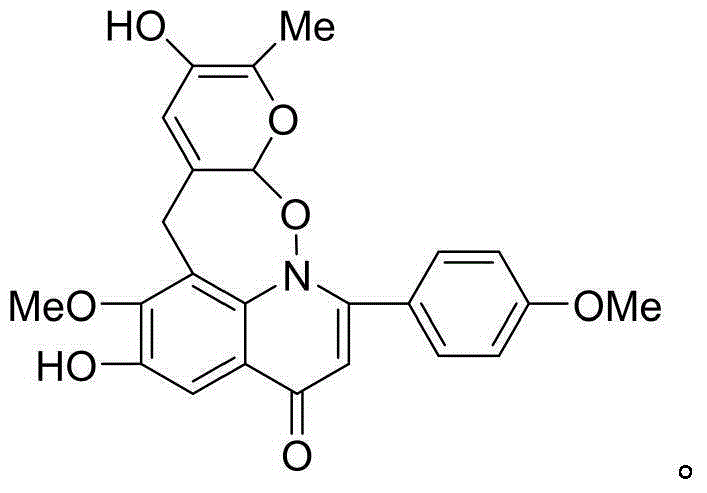

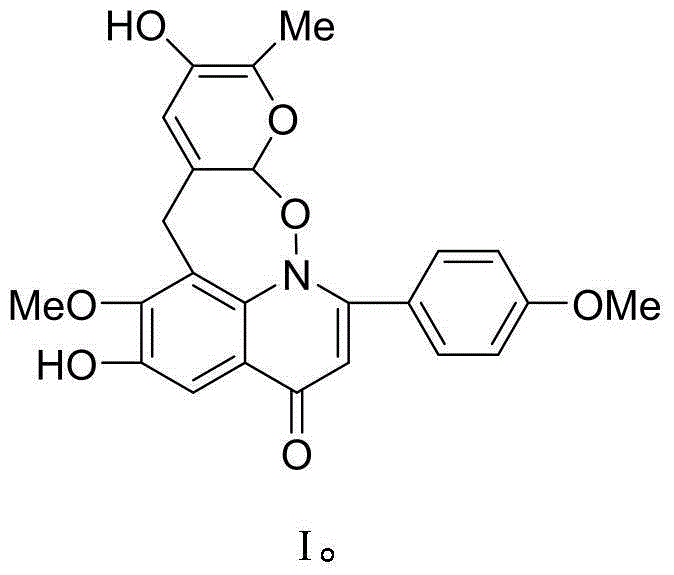

[0093] A finger color added with flash flakes, laser powder, and artificial diamond powder. The raw materials include: 49.81 parts of deionized water, 24.01 parts of polyurethane-35, 16.81 parts of acrylic acid / VP cross-linking polymerization 4.32 parts of hydroxypropyl methylcellulose, 1.02 parts of triethanolamine, 0.78 parts of laureth-21, 0.01 parts of the compound of formula I, 2.6 parts of polyethylene terephthalate, 0.14 1 part of aluminum, 0.1 part of glycerin, 0.42 part of colorant, 0.11 part of white, 0.31 part of red, 2 parts of flash flakes, laser powder and artificial diamond mixture.

[0094] Prepare as follows:

[0095] (1) Mix and stir the hydroxypropyl methylcellulose and triethanolamine evenly to form the first mixture, which is set aside;

[0096](2) Take 30-35 parts of deionized water, 33 parts in the example, and add polyurethane-35, acrylic acid / VP cross-linked polymer, and 0.01 part of the compound of formula I at 60-80°C, preferably 75°C In deionized ...

Embodiment 2

[0105] A finger color added with flash flakes, laser powder, and artificial diamond powder. The raw materials include: 52 parts of deionized water, 25 parts of polyurethane-35, and 17 parts of acrylic acid / VP cross-linking polymerization 4.5 parts of hydroxypropyl methylcellulose, 1.5 parts of triethanolamine, 0.8 parts of laureth-21, 0.02 parts of the compound of formula I, 2.8 parts of polyethylene terephthalate, 0.15 1 part of aluminum, 0.15 part of glycerin, 0.5 part of coloring agent, the specific color can be determined according to demand, 3 parts of flash flakes, laser powder and artificial diamond mixture.

[0106] Its preparation method is similar to Example 1, and its performance parameters are close to Example 1 except for the color.

Embodiment 3

[0108] A finger color added with flash flakes, laser powder, and artificial diamond powder. Its raw materials include: 49 parts of deionized water, 23 parts of polyurethane-35, 16 parts of acrylic acid / VP cross-linking polymerization 4 parts of hydroxypropyl methylcellulose, 0.9 parts of triethanolamine, 0.7 parts of laureth-21, 0.03 parts of the compound of formula I, 1.2 parts of polyethylene terephthalate, 0.05 1 part of aluminum, 0.09 part of glycerin, 0.4 part of coloring agent, the specific color can be determined on demand, 1 part of a mixture of flash flakes, laser powder and artificial diamond.

[0109] Its preparation method is similar to Example 1, and its performance parameters are close to Example 1 except for the color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com