Method for rapidly detecting sealing performance of battery box

A battery box, sealing technology, applied in primary battery use/repair, battery/battery leakage test, secondary battery repair/maintenance, etc., can solve the problems of high detection cost, low efficiency, high IP67 cost, and reduce detection cost, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

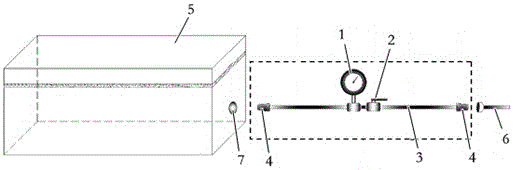

[0017] figure 1 Shows the principle diagram of the inflator device used for testing the sealing of the battery box in the method of the present invention. The inflator device includes a pressure gauge 1, a control switch 2 and a hose 3 for connection. The air nozzle 4 is provided at the connection of the air source 6, which can quickly dock the inflator with the air inlet of the battery box, and the inflator with the external air source, to ensure that the inflator does not leak during the air intake and pressure maintaining stages, and improve work efficiency. The pressure gauge 1 is used to display the current pressure state of the battery box, the control switch 2 can control the closed state of the compressed air intake, when the control switch 2 is turned on, the compressed air flows into the battery box 5 through the hose 3, and the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com