In-situ dynamic monitoring system for internal microenvironment parameters of concrete

A dynamic monitoring and concrete technology, which is applied in the direction of measuring devices, instruments, and electrochemical variables of materials, can solve the problems of high cost, single monitoring position, and immobile sensing elements, etc., and achieve the effect of compact structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

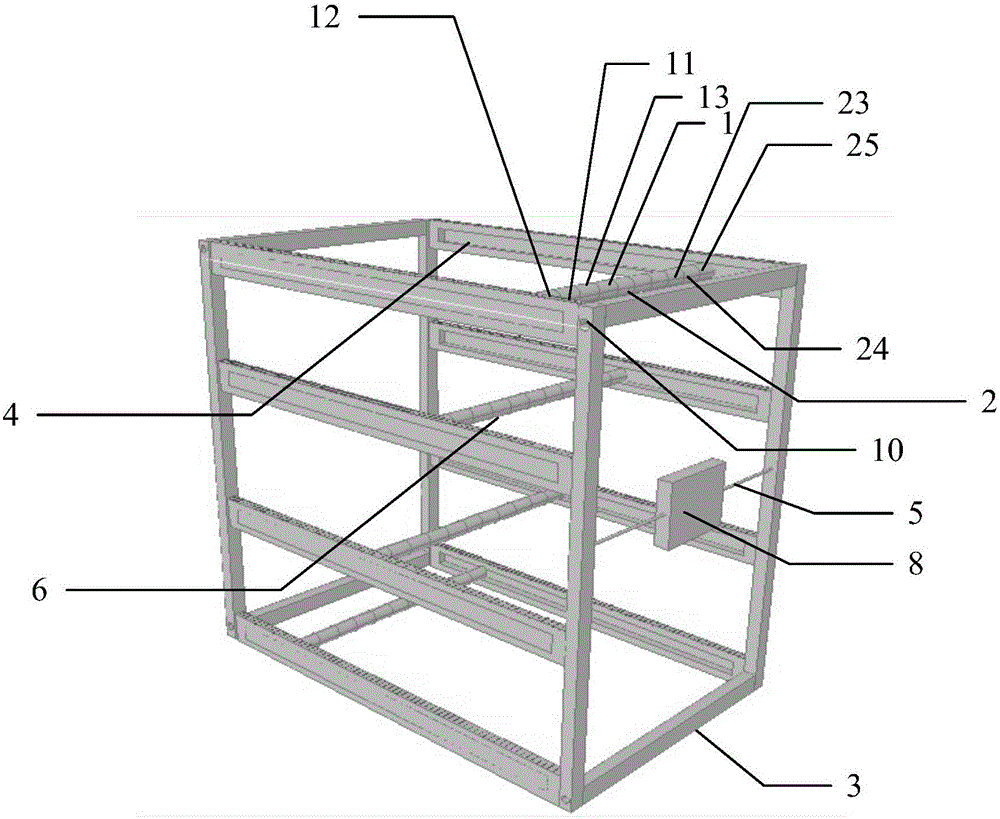

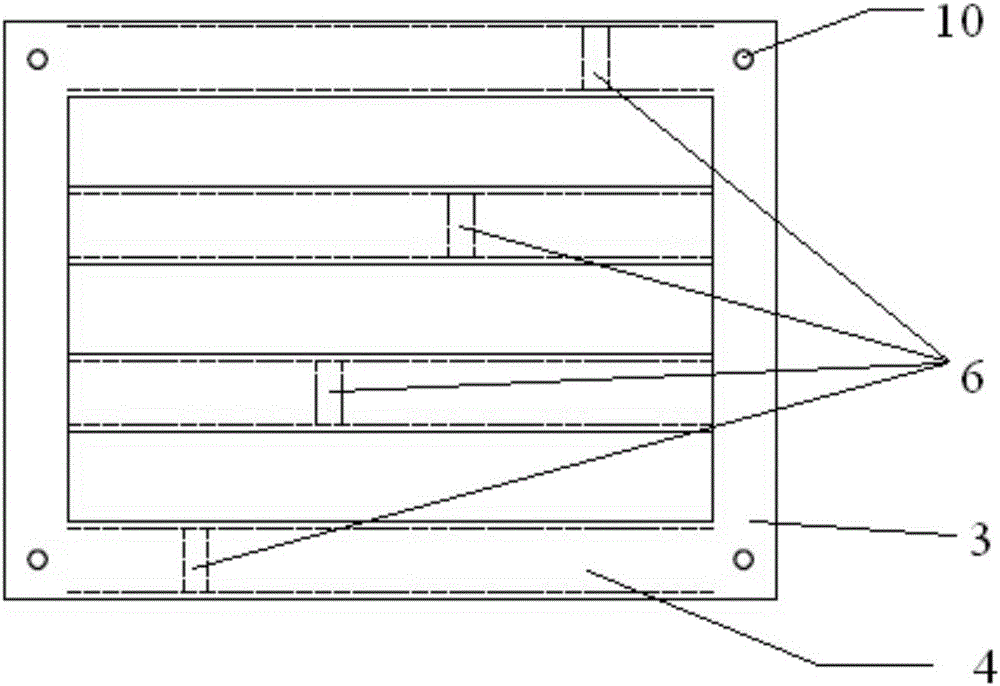

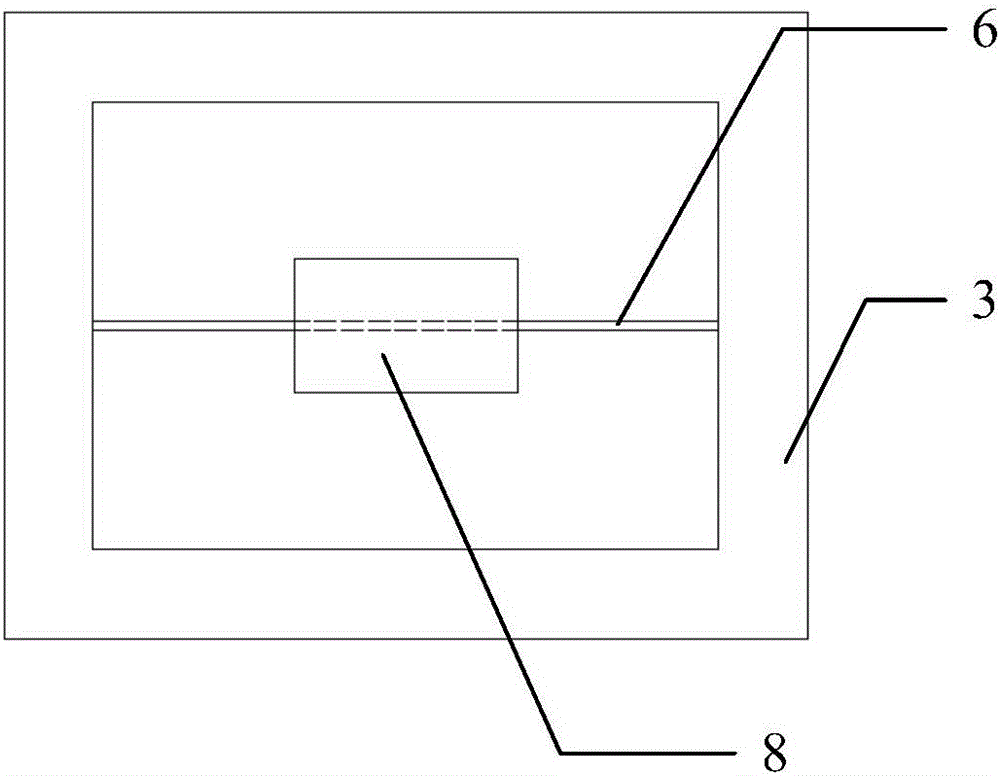

[0039] The invention provides a novel in-situ dynamic monitoring system for internal microenvironment parameters of concrete, which includes:

[0040] Temperature sensor, used to measure the internal temperature of concrete;

[0041] Humidity sensor, used to measure the internal humidity of concrete;

[0042] All-solid chloride ion sensor, used to measure the chloride ion content in concrete;

[0043] All-solid pH sensor, used to measure the pH value of concrete;

[0044] Macro battery sensor, used to measure the corrosion of steel bars in concrete;

[0045] The tetragonal frame is used to connect the sensors into a whole and play a fixed role to prevent the sensor position from changing during installation or concrete pouring.

[0046] The all-solid chloride ion sensor is composed of an all-solid reference electrode and an all-solid chloride ion working electrode.

[0047] The all-solid-state pH sensor is composed of an all-solid-state reference electrode and an all-solid-state pH working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com