Sulfur fumigated neutralization reaction tower

A technology of reaction tower and sulfur fumigation, applied in the direction of purification with alkaline earth compounds, purification with oxidation/reduction, etc., can solve the problems of low cleaning efficiency, fouling and slag blocking, uneven neutralization reaction of sugar juice, etc., to improve adsorption efficiency , avoid waste, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

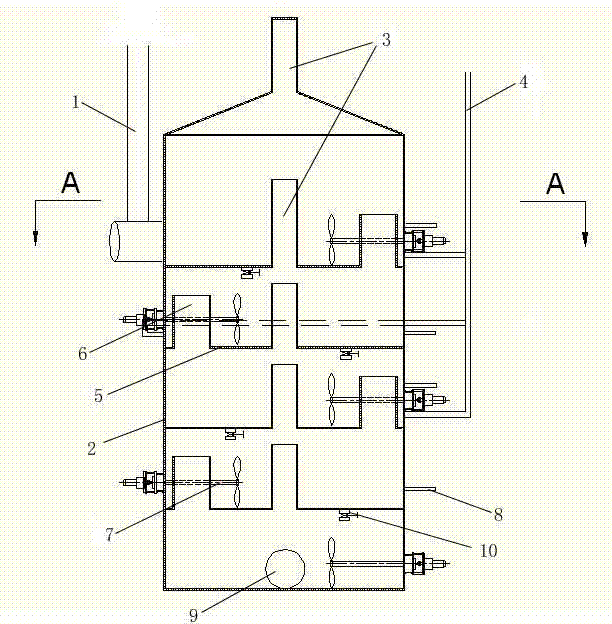

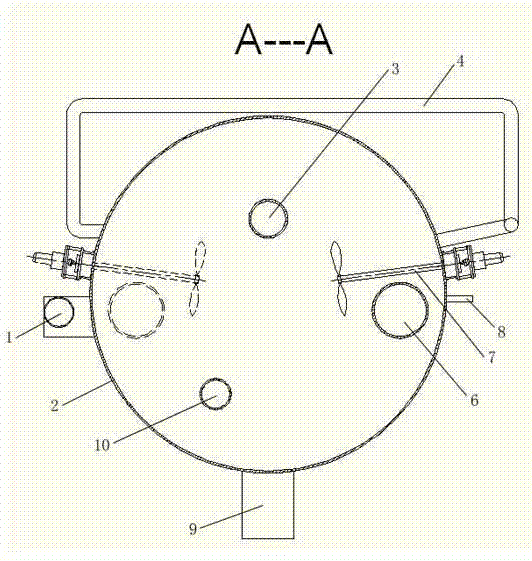

[0029] like figure 1 and figure 2 As shown, the sulfur fumigation neutralization reaction tower includes a sulfur fumigation tail pipe 1, a tank body 2, a gas dispersion pipe 3, and a lime milk adding pipe 4; 2. The interior is divided into 5 reaction layers arranged up and down, and from top to bottom, it is the top reaction layer, No. 2 reaction layer, No. 3 reaction layer, No. 4 reaction layer, and bottom reaction layer; Straight juicing pipes 6, the juicing pipes 6 of each layer are staggered; the sulfur fumigation tail pipe 1 is located on the uppermost reaction layer, and the sulfur fumigation tail pipe 1 comprises the lime milk adding port arranged on it; The top and each clapboard 5 are provided with air-diffusing pipes 3, and the height of the air-diffusing pipes 3 on each clapboard 5 is higher than the height of the juice-passing pipe 6; Inside the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com