Anti-explosion torch

A technology of torch and torch head, which is applied in the field of petrochemical industry, petroleum and oil shale mining, and can solve problems such as explosion, mixed gas backfire, and the torch cannot be recovered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

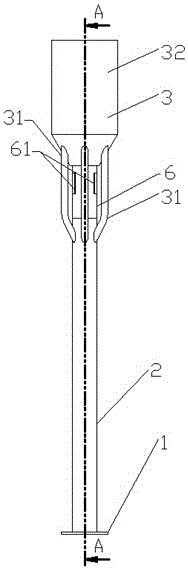

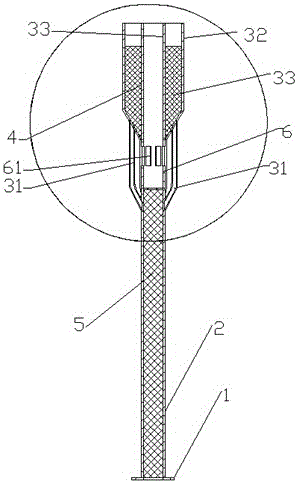

[0017] Example 1: See Figure 1-4 , a torch, comprising: an ignition device, a connecting flange 1, a mixed gas pipeline 2, a heat dissipation shunt pipe 31, and a torch head 3;

[0018] The lower part of the mixed gas pipeline 2 is provided with a connecting flange 1, and the upper part of the mixed gas pipeline 2 is closed;

[0019] The inside of the mixed gas pipeline 2 is filled with a low-temperature flame arresting net 5;

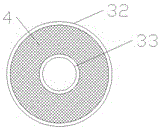

[0020] The torch head 3 is barrel-shaped, with a cooling gas passage 33 in the middle, which runs through up and down, and an annular cavity 34 with a closed lower end and an open upper end is formed between the torch head shell 32 and the cooling gas passage 33;

[0021] The interior of the annular cavity 34 is filled with a high-temperature fire-blocking net 4; a high-temperature fire-blocking net 4 and a low-temperature fire-blocking net 5;

[0022] The lower end of the torch head shell 32 is provided with a heat dissipation shunt pipe 31, and ...

Embodiment 2

[0026] Example 2: See Figure 1-4 , a torch, comprising: an ignition device, a connecting flange 1, a mixed gas pipeline 2, a heat dissipation shunt pipe 31, a torch head 3, a high-temperature fire-blocking net 4, and a low-temperature fire-blocking net 5;

[0027] The lower part of the mixed gas pipeline 2 is provided with a connecting flange 1, and the upper part of the mixed gas pipeline 2 is closed;

[0028] The inside of the mixed gas pipeline 2 is filled with a low-temperature flame arresting net 5;

[0029] The torch head includes a torch head shell 32 and a cooling gas passage 33;

[0030] The torch head 3 is barrel-shaped, with a cooling gas passage 33 in the middle, which runs through up and down, and an annular cavity 34 with a closed lower end and an open upper end is formed between the torch head shell 32 and the cooling gas passage 33;

[0031] The interior of the annular cavity 34 is filled with a high-temperature fire-blocking net 4;

[0032] The lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com