EMU Traction Transformer Oil Pump Remote Fault Monitoring and Early Warning System and Method

A traction transformer and fault monitoring technology, applied in the field of transformer oil pumps, can solve problems such as inability to intuitively respond to fault conditions, inability to use information management, and inability to realize remote monitoring and early warning, so as to ensure timeliness and effectiveness and improve customer The effect of experience and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

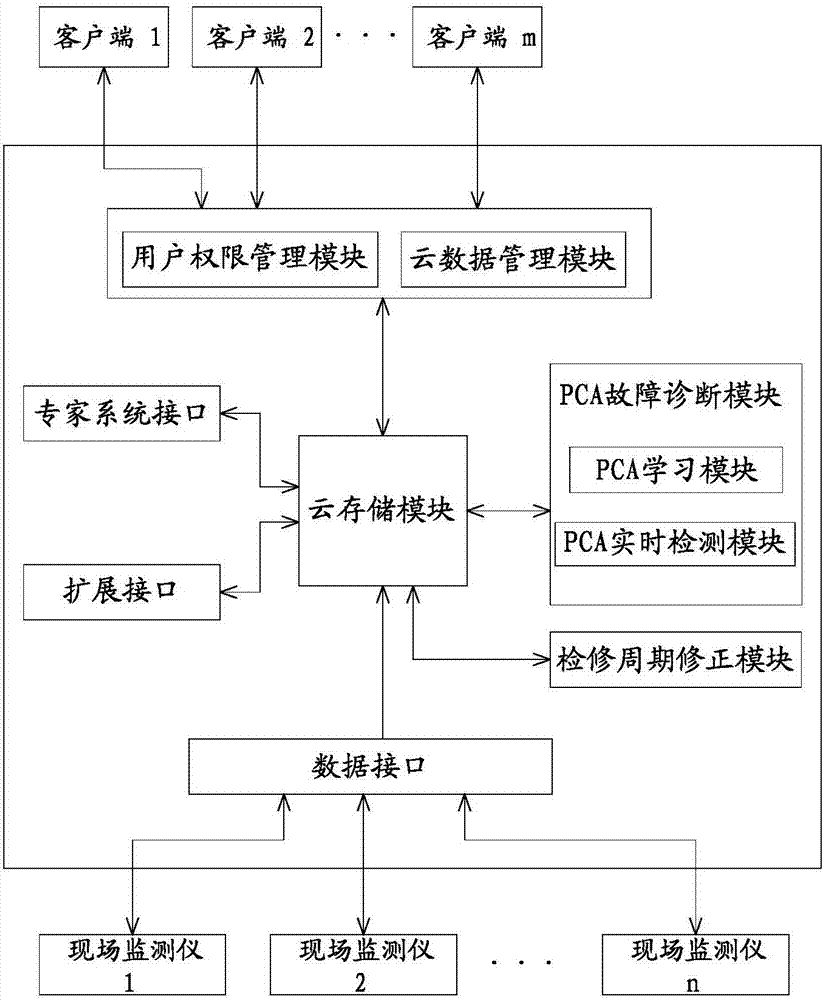

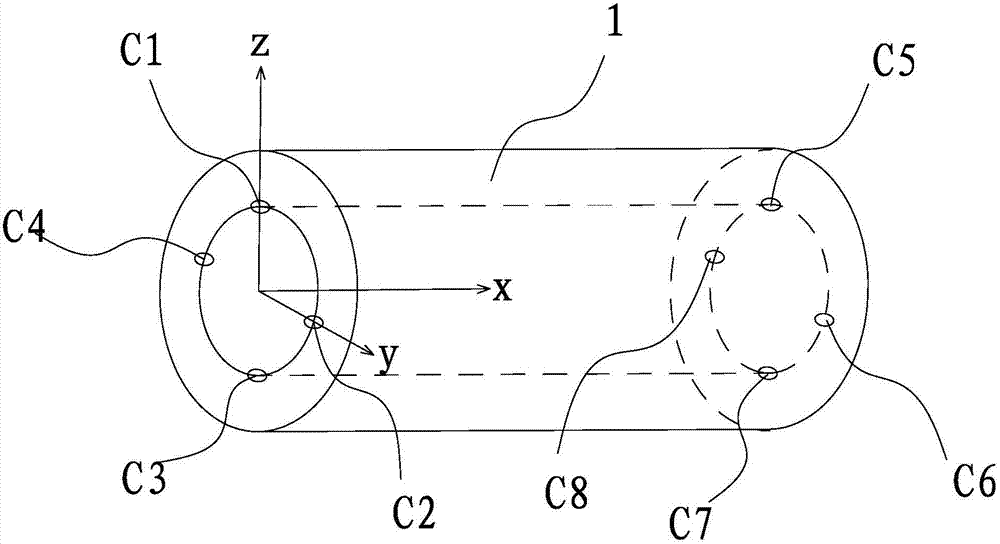

[0039] Such as figure 1 As shown, the EMU traction transformer oil pump remote fault monitoring and early warning system includes on-site monitors, cloud computing centers and clients. There are n on-site monitors, m clients, n on-site monitors and m clients Each is configured with a unique identification barcode and is connected to the cloud computing center through a wireless network. Each on-site monitor is used to detect the offset of the corresponding transformer rotor bearing 2 and output the detection results. In detail, the offset of the rotor bearing 2 includes its X-axis direction, Y-axis direction and Z-axis direction. displacement, the X-axis, Y-axis and Z-axis are three mutually perpendicular coordinate axes of a spatial Cartesian coordinate system established with the center of one end face of the rotor bearing 2 as the origin and the axis line of the rotor bearing 2 as the X-axis , the X axis is a horizontal axis, the Y axis is a vertical axis, and the Z axis i...

Embodiment 2

[0048] Such as Figure 9 As shown, in this embodiment, the EMU traction transformer oil pump remote fault monitoring and early warning system is basically the same as in Embodiment 1, the difference is that the EMU traction transformer oil pump remote fault monitoring and early warning system in this embodiment It also includes the enterprise data center, which is connected to the cloud computing center through a wireless network, and the enterprise data center receives and backs up the data of the cloud computing center. The enterprise data center mentioned here mainly serves the oil pump production enterprises. Through the enterprise data center, the operation data of the oil pump can be backed up to ensure the security of the data, which can facilitate the analysis and research of the data by the oil pump production enterprises.

Embodiment 3

[0050] Such as Figure 10 As shown, in this embodiment, the EMU traction transformer oil pump remote fault monitoring and early warning system is basically the same as in Embodiment 1, the difference is that the field monitor in this embodiment also includes The current acquisition module and the GPS module for positioning the on-site monitor are connected with the controller. The working condition of the oil pump can be further judged by collecting the working current of the oil pump; the location management of the oil pump is facilitated by setting the GPS module.

[0051] Such as Figure 8 As shown, the remote fault monitoring and early warning method of the traction transformer oil pump of the EMU comprises the following steps:

[0052] A. Establish the PCA principal component model: collect the historical operation data of the oil pump under normal working conditions through the on-site monitor, and then input the historical operation data into the cloud computing cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com