Cooling pipeline of double-turbine pressurizing plug-in type hybrid power system and manufacturing technology of cooling pipeline

A technology of hybrid power system and cooling pipeline, applied in the direction of engine cooling, tubular objects, engine components, etc., can solve the problems of engine efficiency reduction, accelerated component wear, etc., to increase service life, improve product performance, and shorten vulcanization time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

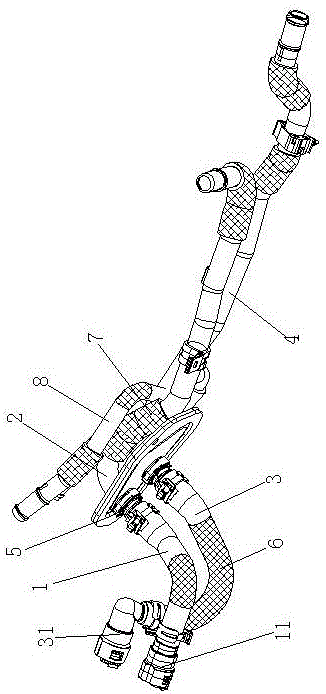

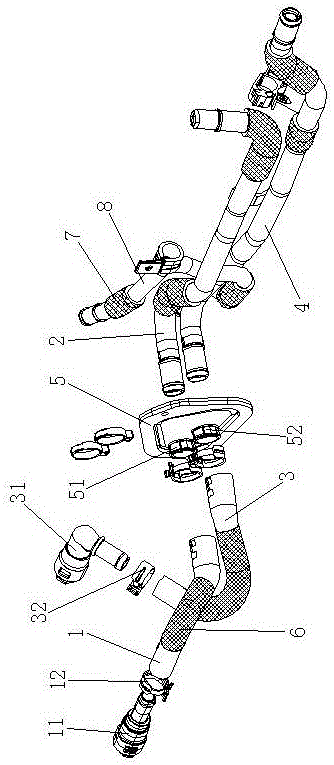

[0046] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

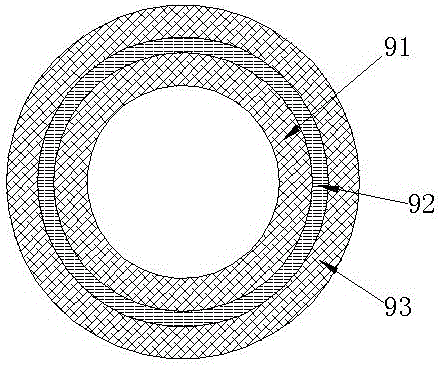

[0047] The reference signs are: the first rubber tube 1, the first quick joint 11, the first clamp 12, the first aluminum tube 2, the second rubber tube 3, the second quick joint 31, the second clamp 32, the first An aluminum tube 4, a reference plate 5, a first connecting pipe 51, a second connecting pipe 52, a braided sheath 6, a sponge sheath 7, a branch pipe 8, an inner rubber layer 91, a fiber reinforced layer 92, and an outer rubber layer 93.

[0048] Such as Figure 1 to Figure 3 as shown,

[0049] The cooling pipeline of the twin-turbocharged plug-in hybrid power system of the present invention includes a first cooling pipe and a second cooling pipe, the first cooling pipe is formed by connecting the first rubber pipe 1 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com