A kind of ultra-fine silk spinning oil and preparation method

A technology of spinning oil and ultra-fine filaments, which is applied in textiles, papermaking, fiber treatment, etc. It can solve the problems of super washability and degradation of textile oiling agent residues, achieve excellent antistatic properties, and simple production process , good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

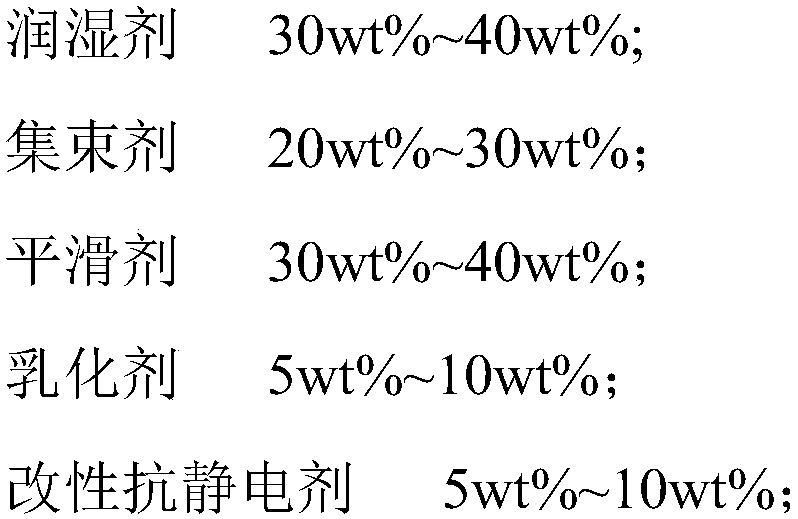

Method used

Image

Examples

preparation example Construction

[0031] Preparation of modified antistatic agent:

[0032] Add 15 parts of C8-C12 fatty alcohol into the reactor, heat and dissolve, and stir evenly. Lower the temperature to below 40°C, slowly add 8 parts of phosphorus pentoxide under stirring, control the reaction temperature below 40°C, and finish adding Afterwards, the temperature was raised to 50° C., and the reaction was maintained for 4 hours. After cooling down to room temperature, potassium hydroxide was added to neutralize to PH=7. Add 1 part each of LYCO-P08, LYCO-P30, and LYCO-P16 produced by LYCOMAX produced by a special catalytic esterification method, stir for 10 minutes, add 3 parts of HEDP produced by Xinyuan Biochemical Company, stir for 10 minutes, add 0.03 parts of borax, and stir for 20 minutes minute. The modified antistatic agent is obtained.

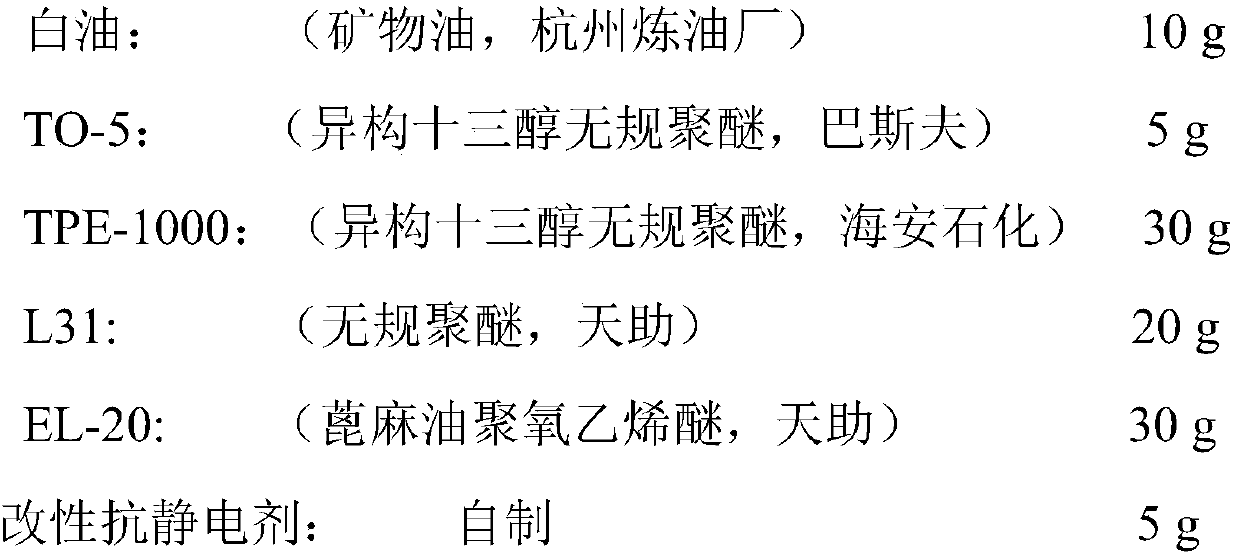

Embodiment 1

[0034]

[0035] Process:

[0036] Add smoothing agent (white oil) and emulsifier (TO-5) into the reactor in a certain proportion, and emulsify at 45°C with high-speed stirring (200 rpm) for 30 minutes to obtain a stable smoothing agent;

[0037] Then add wetting agent and sizing agent sequentially under stirring, and finally add self-made modified antistatic agent, and stir for 20 minutes to obtain colorless or light yellow transparent ultra-fine filament spinning oil for electronic field.

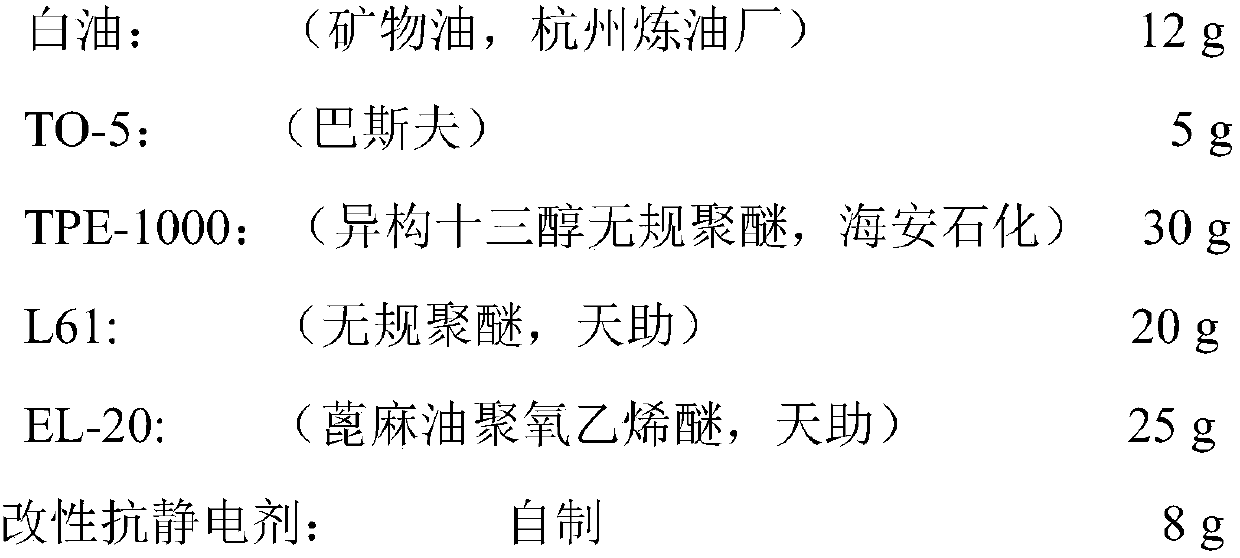

Embodiment 2

[0039]

[0040] Process:

[0041] Add smoothing agent (white oil) and emulsifier (TO-5) into the reactor in a certain proportion, and emulsify at 45°C with high-speed stirring (200 rpm) for 30 minutes to obtain a stable smoothing agent;

[0042] Then add wetting agent and sizing agent sequentially under stirring, and finally add self-made modified antistatic agent, and stir for 20 minutes to obtain colorless or light yellow transparent ultra-fine filament spinning oil for electronic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com