Composite nano material capable of exciting upconversion steady persistence through near-infrared light and preparation thereof

A composite nanomaterial and nanomaterial technology, applied in the field of near-infrared light-excited up-conversion long-lasting composite nanomaterials and its preparation, can solve problems such as low luminous efficiency, shallow penetration depth, and reduced in vivo imaging efficiency, achieving high Signal-to-noise ratio, the effect of simple detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

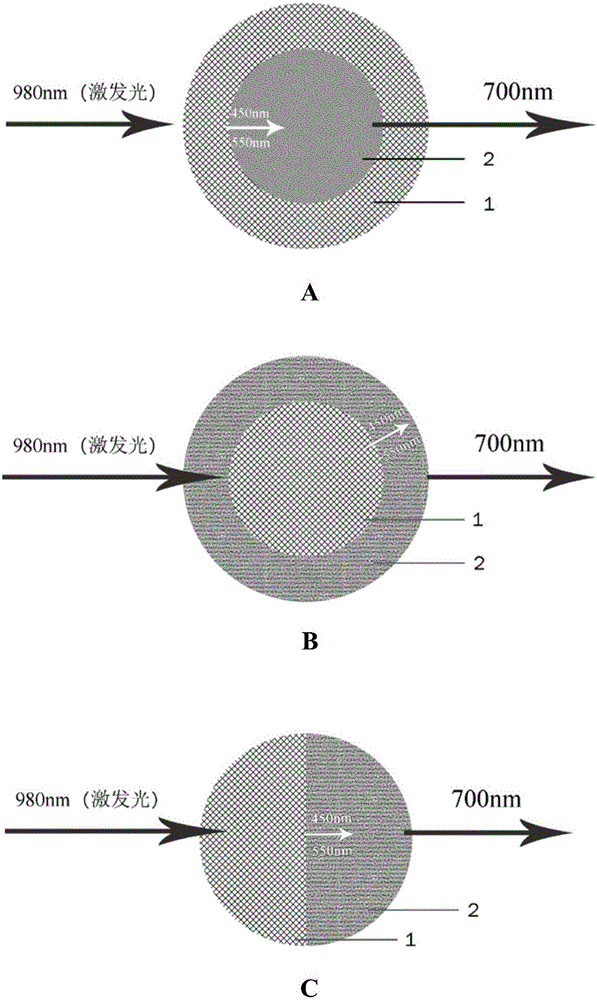

[0047] Example 1: Preparation of composite nanomaterials with long afterglow upconversion excited by near-infrared light

[0048] Preparation of Long Persistence ZnO Nanomaterial Zn 1.1 Ga 1.8 Ge 0.1 o 4 : Cr 3+ 0.005 Nanoparticles, the specific method is as follows: 16.134mmolGa 2 o 3 10mL of 35% concentrated nitric acid was reacted overnight at 150°C under hydrothermal conditions to obtain Ga and Ge chloride salt products; 0.004mmol of chromium nitrate and 8.97mmol of zinc nitrate were dissolved in 10mL of water, and 0.894mmol of GeO was dissolved in as little ammonia water as possible , and the solution was transferred to the above gallium nitrate solution and stirred vigorously, and the resulting solution was washed with 30% NH 3 ·H 2 O to adjust the pH to 7.5 and stir at room temperature for 3 h; after stirring, transfer the solution to a 25 mL stainless steel high-temperature steam sterilizer with an insulated edge and heat at 120 ° C for 24 h; the above products...

example 2

[0051] Example 2: Preparation of composite nanomaterials with long afterglow upconversion excited by near-infrared light

[0052] Preparation of Long Persistence Nanomaterial Zn 1.1 Ga 1.8 Ge 0.1 o 4 : Cr 3+ 0.005 Nanoparticles, the specific method is as follows:

[0053] 16.134 mmol Ga 2 o 3 10mL of 35% concentrated nitric acid was reacted overnight at 150°C under hydrothermal conditions to obtain the chloride salt products of Ga and Ge; 0.004mmol of chromium nitrate and 8.97mmol of zinc nitrate were dissolved in 10mL of water, and 0.894mmol of GeO was dissolved in as little as possible ammonia water, and the solution was transferred to the above gallium nitrate solution and vigorously stirred, and the resulting solution was washed with 30% NH 3 ·H 2 O to adjust the pH to 7.5 and stir at room temperature for 3 h; after stirring, transfer the solution to a 25 mL stainless steel high-temperature steam sterilizer with an insulated edge and heat at 120 ° C for 24 h; the ...

example 3

[0056] Example 3: Preparation of composite nanomaterials with long afterglow upconversion excited by near-infrared light

[0057] Preparation of Long Persistence Nanomaterial Zn 1.1 Ga 1.8 Ge 0.1 o 4 : Cr 3+ 0.005 Nanoparticles, the specific method is as follows:

[0058] 16.134 mmol Ga 2 o 3 , 10mL of 35% concentrated nitric acid was reacted overnight at 150°C under hydrothermal conditions to obtain the chloride salt products of Ga and Ge; 0.004mmol of chromium nitrate and 8.97mmol of zinc nitrate were dissolved in 10mL of water, and 0.894mmol of GeO was dissolved in as little as possible ammonia water, and the solution was transferred to the above gallium nitrate solution and vigorously stirred, and the resulting solution was washed with 30% NH 3 ·H 2 O to adjust the pH to 7.5 and stir at room temperature for 3 h; after stirring, transfer the solution to a 25 mL stainless steel high-temperature steam sterilizer with an insulated edge and heat at 120 °C for 24 h; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com