Wastewater lifting device for producing dioctyl phthalate

A technology of dioctyl phthalate and waste water, which is applied in the direction of grease/oily substance/suspton removal device, water/sewage multi-stage treatment, heating water/sewage treatment, etc., and can solve problems such as environmental pollution and waste of raw materials , to achieve the effects of reducing pollution, increasing stratification time, and reducing water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

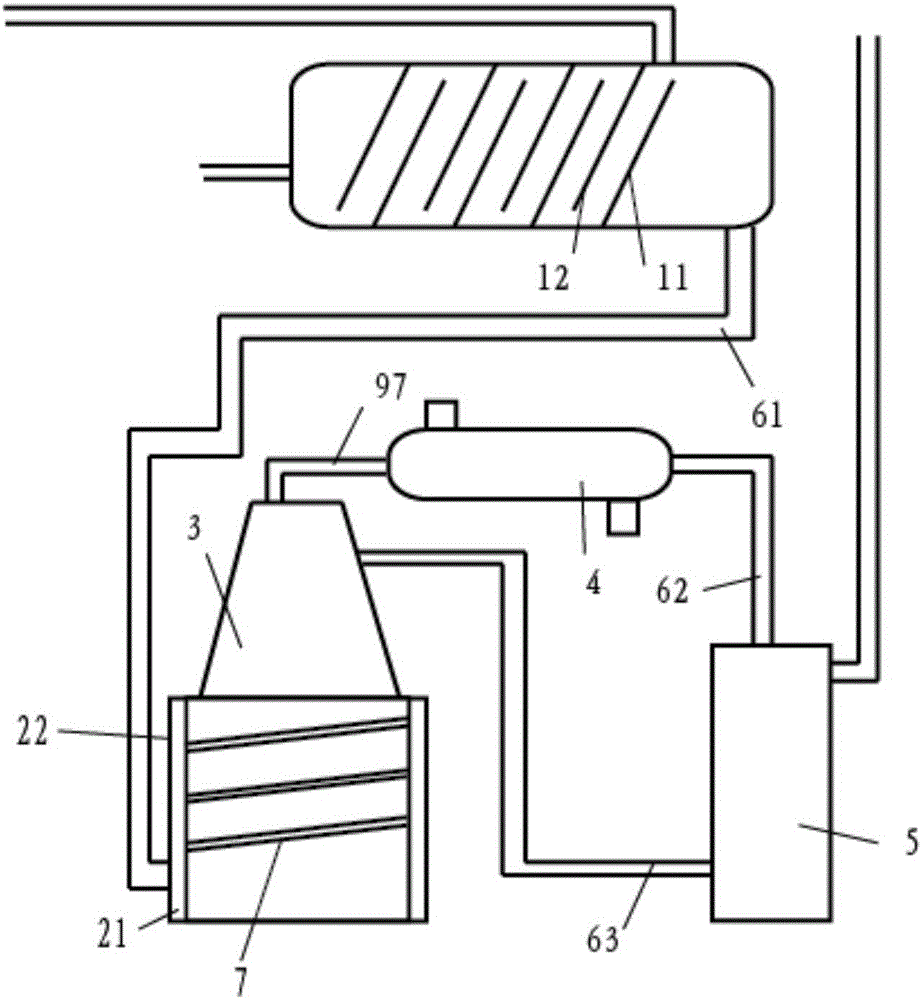

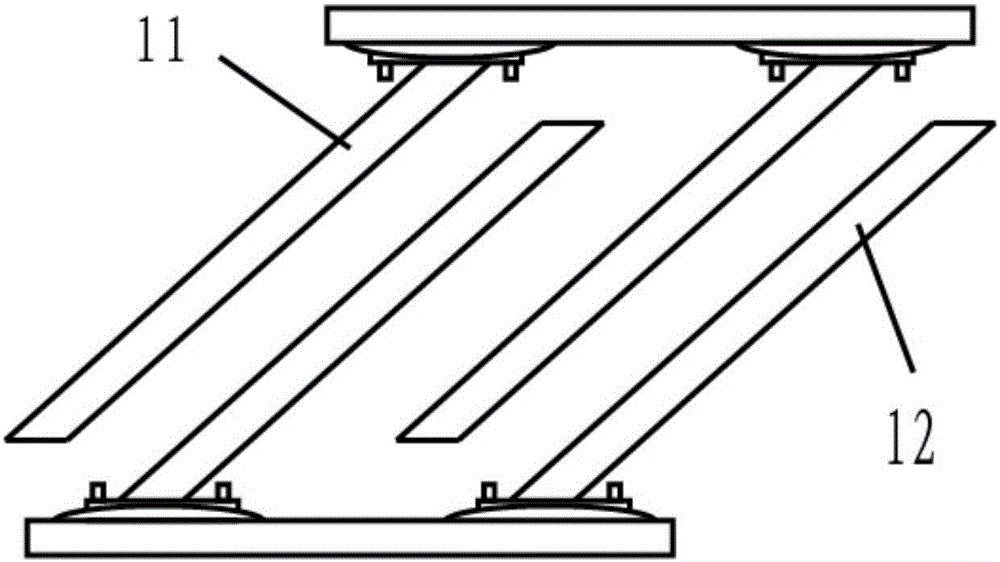

[0023] Such as Figure 1-2 As shown, the present invention discloses a waste water extraction device for producing dioctyl phthalate, including a horizontal separation tank, a heating tank, a waste water tower 3, a condenser 4, and a liquid separation tank 5. The front end of the horizontal separation tank is provided with a feed inlet, the top of the rear end of the horizontal separation tank is provided with an ester return port, and the bottom of the rear end of the horizontal separation tank is provided with a waste water outlet.

[0024] The waste water outlet is communicated with the heating tank through the first pipeline 61, and the top of the heating tank is provided with a waste water tower 3, and the top of the waste water tower 3 is communicated with the air inlet of the condenser 4, and the liquid outlet of the condenser 4 is through the second pipeline 62 It communicates with the upper end of the liquid separation tank 5.

[0025] A water outlet and an alcohol o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com