A fully automatic plastic mobile phone case grinding equipment

A mobile phone case, fully automatic technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding head, etc., can solve the problems of low grinding efficiency, unsuitable for large-scale grinding operations, low degree of automation, etc., to achieve work efficiency and The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

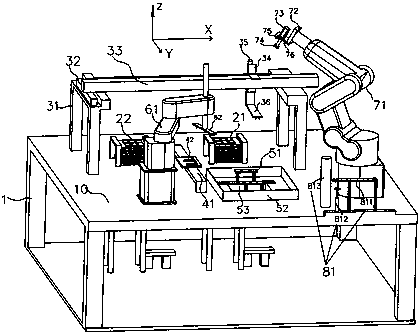

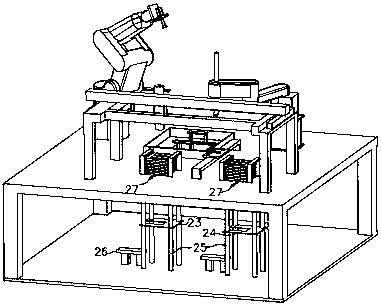

[0019] Such as Figure 1 to Figure 2 , an embodiment of a full-automatic plastic mobile phone shell grinding equipment, comprising a machine 1, the machine 1 has a horizontal platform 10, and the machine 1 is provided with a feeding mechanism 21 and a recycling machine for supplying the mobile phone shell to be processed. The receiving mechanism 22 of the processed mobile phone case, the horizontal platform 10 is provided with a gantry 31 bridged over the feeding mechanism 21 and the receiving mechanism 22, and the gantry 31 is provided with a first Y-axis mold Group 32, the first Y-axis type module 32 drives an X-axis type module 33 slidably arranged on the gantry to move along the Y-axis, and the X-axis type module 33 drives a reclaiming slide block slidably arranged on it 34 moves al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com