Preparation method and application of magnetic CuxO-Fe2O3 nano ozone catalyst

A cuxo-fe2o3, magnetic nano technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of low mineralization rate efficiency and small pH application range , high cost of nanoparticle preparation and other issues, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

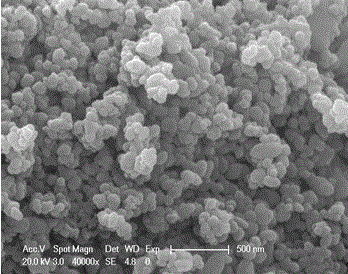

[0032] (1) Cu x O-Fe 2 o 3 Preparation: Cu(NO 3 ) 2 ·3H 2 Dissolve O in water, stirring and dissolving to form 0.1mol / L Cu(NO 3 ) 2 solution, then add 5.6g of iron powder and 0.1‰ volume of ammonium citrate dispersant to 100mL of the solution, mechanically stir at 120°C for 1h, dry the solid particles and the solution at 110°C for 3h, and finally place the solid in Calcined at 500°C for 1 h to obtain Cu x O-Fe 2 o 3 Magnetic Nanomaterials. Its SEM photo see figure 1 , the catalyst is a uniform ellipsoid particle with a size of about 60nm.

[0033] (2) Preparation of CuO: Cu(NO 3 ) 2 ·3H 2 Dissolve O in water, stirring and dissolving to form 0.1mol / L Cu(NO 3 ) 2 solution, then add 0.1‰ volume of ammonium citrate dispersant to 100mL of the solution, mechanically stir at 120°C for 1h, dry the solid particles and the solution at 110°C for 3h, and finally calcinate the solid at 500°C for 1.5h , to get CuO.

[0034] (3) Fe 2 o 3 Preparation: Add 5.6g of iron powd...

Embodiment 2

[0036] Cu(NO 3 ) 2 ·3H 2 Dissolve O in water, stirring and dissolving to form 0.2mol / L Cu(NO 3 ) 2 solution, then add 5.6g of iron powder and 0.5‰ volume of sodium citrate dispersant to 100mL of the solution, mechanically stir at 120°C for 1.5h, dry the solid particles and the solution at 100°C for 4h, and finally dissolve the solid Calcined at 450°C for 2h to obtain Cu x O-Fe 2 o 3 Magnetic Nanomaterials.

Embodiment 3

[0038] Cu x O-Fe 2 o 3 Preparation: Cu(NO 3 ) 2 ·3H 2 Dissolve O in water, stirring and dissolving to form 0.1mol / L Cu(NO 3 ) 2 solution, then add 11.2g of iron powder and 1‰ volume of potassium citrate dispersant to 100mL of the solution, mechanically stir at 120°C for 2h, dry the solid particles and the solution at 120°C for 2h, and finally place the solid in Calcined at 550°C for 2h to obtain Cu x O-Fe 2 o 3 Magnetic Nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com