Analytical method of iodine-containing hydriodic acid concentration

An analysis method, the technology of hydroiodic acid, applied in the field of electrochemical and chemical analysis, can solve the problems of poor repeatability, cumbersome operation, time-consuming process, etc., achieve accurate analysis results, overcome cumbersome operation, and convenient and fast data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

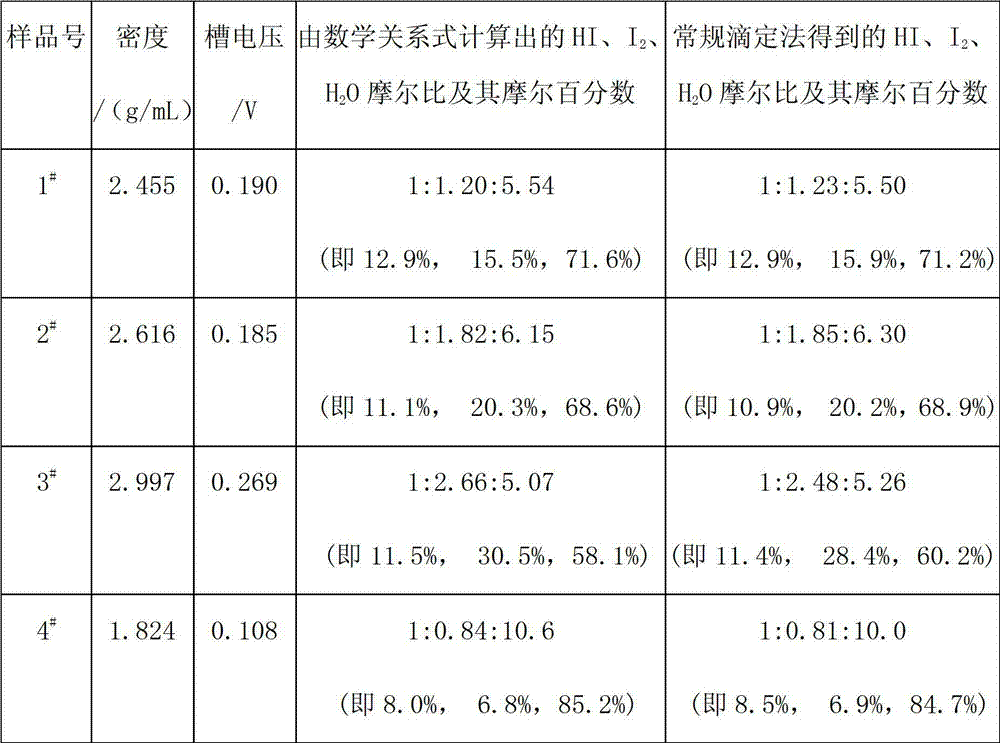

[0043] Density measurements were carried out with an Anton Paar DMA 4100M U-tube oscillating density meter. The electrolysis-electrodialysis cell adopts DuPont's Nafion 117 proton exchange membrane, which separates the cathode and anode. The distance between the cathode and anode electrodes is 2mm, and the effective exchange area of the electrolysis-electrodialysis cell is 25cm 2 . The electrolysis-electrodialysis cell is equipped with a temperature controller, a constant current DC power supply and a voltmeter for measuring cell voltage. Prepare HI:I 2 :H 2 The molar ratio of O is 1:0.2~4.0:4.0~13. A series of iodine-containing hydroiodic acid standard samples with different concentrations in the range of 1:0.2~4.0:4.0~13 are measured by the aforementioned U-tube oscillating density meter at normal pressure and 80°C. Density value; Under normal pressure and constant current conditions, measure the cell voltage value of the above-mentioned standard samples when they flow ...

Embodiment 2

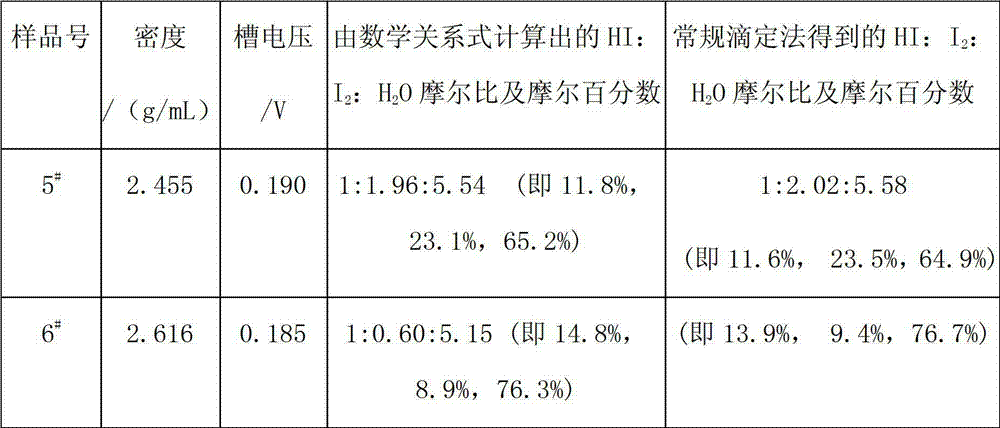

[0051] As listed in the table below, for 5 # and 6 # Contain iodohydriodic acid sample to be measured and carry out concentration analysis, under normal pressure, adopt measuring cylinder to take the sample of certain quality, and read out the volume of sample taken by weighing, thereby calculate density, and with the constant current described in embodiment one Electrolysis-electrodialysis cell and its conditions, carried out 5 # and 6 #样 Determination of the cell voltage value when the product flows through the constant current electrolysis-electrodialysis cell. According to the obtained density value and the cell voltage value when the sample flows through the constant current electrolysis-electrodialysis cell, according to the mathematical relationship obtained in Example 1, calculate 5 # and 6 # concentration of the sample. As a comparison, the table also lists the 5 # and 6 # The concentration of the No. sample.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com