Load type duplex metal/multi-metal catalyst for hydrogenation synthesis of metanilic acid from m-Nitrobenzenesulfonic acid and preparation method and application

A multi-metal catalyst, nitrobenzene sulfonic acid technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, sulfonic acid preparation, physical/chemical process catalyst, etc., can solve the problem of high catalyst, achieve high activity and Effects of stability, cost reduction, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

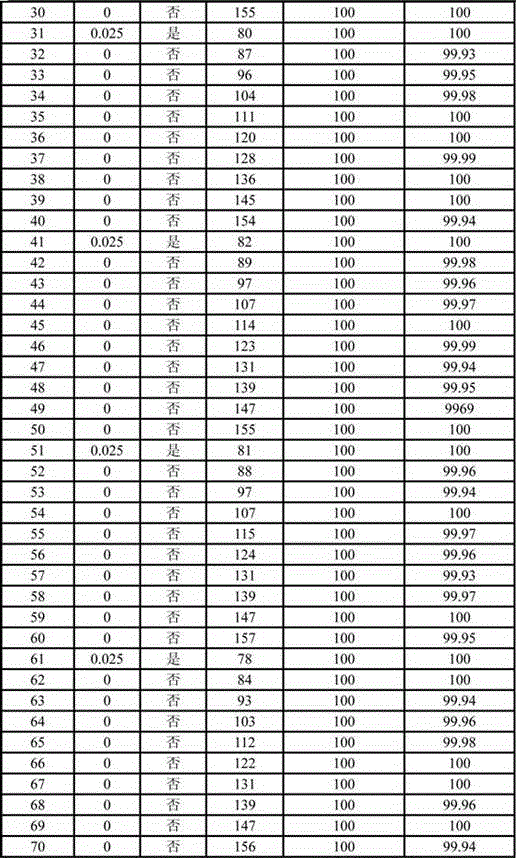

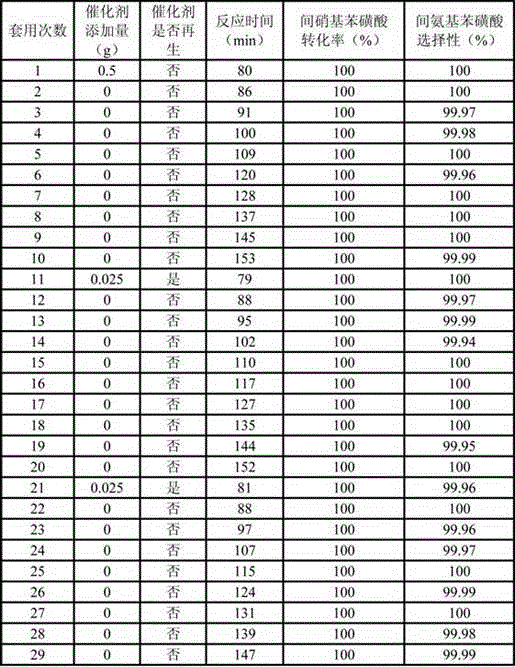

Examples

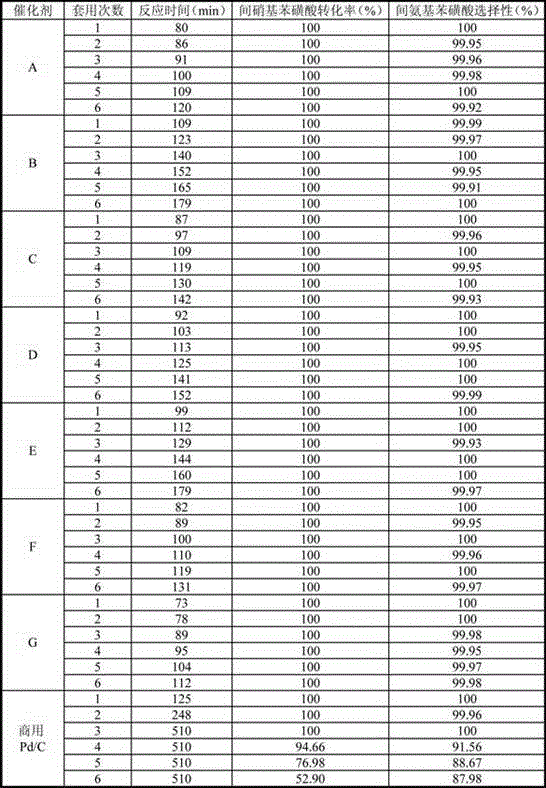

Embodiment 1

[0031] Weigh 3.5gAl 2 o 3 The carrier was poured into the flask, and then 100ml of a mixed solution of deionized water and glycerol at a ratio of 50:1 was added, and kept at a constant temperature of 90° C. in a water bath for 60 minutes under stirring. Then, 2 ml of 0.05 g / ml palladium nitrate solution and 1 ml of 0.05 g / ml platinum nitrate solution prepared in advance were added dropwise to the carrier, and kept at constant temperature for 2 hours. After the impregnation is completed, use lmol / mlNa 2 CO 3 The solution adjusts the pH value of the impregnating solution to 12, and maintains it for 100 minutes. Then the precipitate was transferred to a suction filter bottle for suction filtration, washed, dried at 80°C for 4h, calcined at 500°C for 4h, and finally reduced with H2 at 500°C for 1h to obtain Pd-Pt / Al 2 o 3 Catalyst, record catalyst A.

Embodiment 2

[0033] Weigh 3.5gAl 2 o 3 The carrier was poured into the flask, and then 100ml of a mixed solution of deionized water and glycerol at a ratio of 50:1 was added, and kept at a constant temperature of 90° C. in a water bath for 60 minutes under stirring. Then, 2 ml of 0.05 g / ml chloropalladium acid solution and 1 ml of 0.05 g / ml chloroplatinic acid prepared in advance were added dropwise to the carrier, and kept at constant temperature for 2 hours. After the impregnation is completed, use lmol / mlNa 2 CO 3 The solution adjusts the pH value of the impregnating solution to 12, and maintains it for 100 minutes. Then the precipitate was transferred to a suction filter bottle for suction filtration, washed, dried at 80°C for 4h, roasted at 500°C for 4h, and finally washed with H at 500°C. 2 After reduction for 1h, Pd-Pt / Al is obtained 2 o 3 Catalyst, record catalyst B.

Embodiment 3

[0035]Weigh 3.5g of the SiO2 carrier and pour it into a flask, then add 100ml of a mixed solution of deionized water and glycerol at a ratio of 50:1, and keep it in a water bath at 90°C for 60min under stirring. Then, 2ml of 0.05g / ml chloroplatinic acid solution and 1ml of 0.05g / ml cerium nitrate prepared in advance were added dropwise to the carrier, and kept at constant temperature for 2h. After the impregnation is completed, adjust the pH value of the impregnation solution to 12 with 1mol / ml Na2CO3 solution, and keep it for 100min. Then the precipitate was transferred to a suction filter bottle for suction filtration, washed, dried at 80°C for 4h, roasted at 500°C for 4h, and finally washed with H at 500°C. 2 After reduction for 1h, the corresponding Pt-Ce / SiO can be obtained 2 Catalyst, record catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com