Display substrate, preparation method thereof and display device

A technology for display substrates and display areas, applied in identification devices, lighting devices, air-proof/water-proof devices, etc., can solve the problems of easy-to-touch display areas 1 and corner light leakage of display panels, and achieve good stability and uniformity. The effect of preventing light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

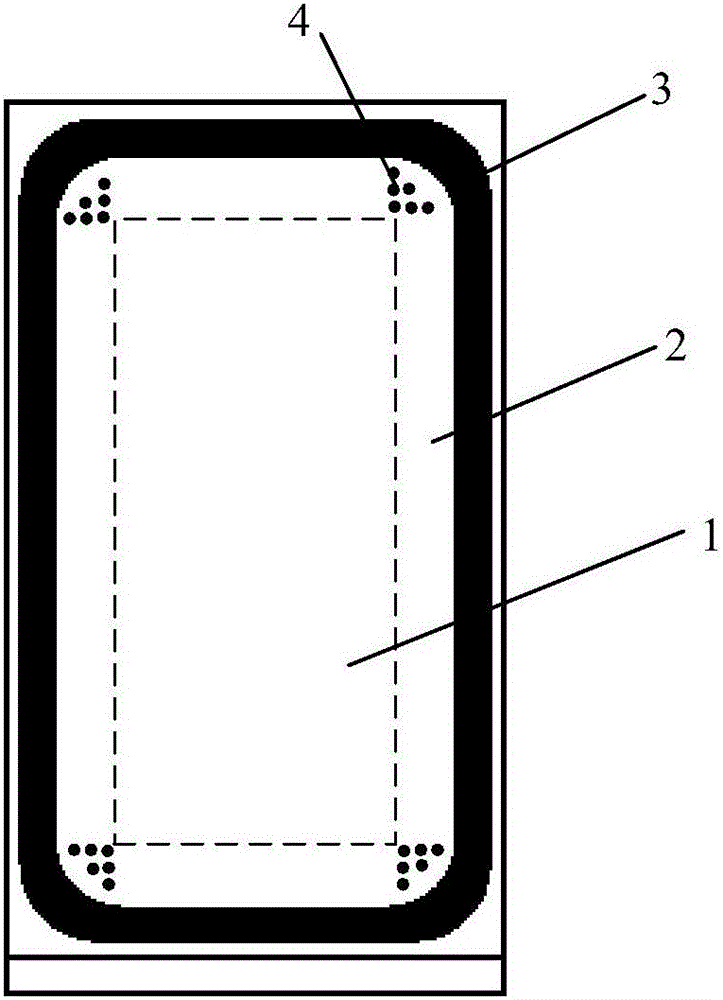

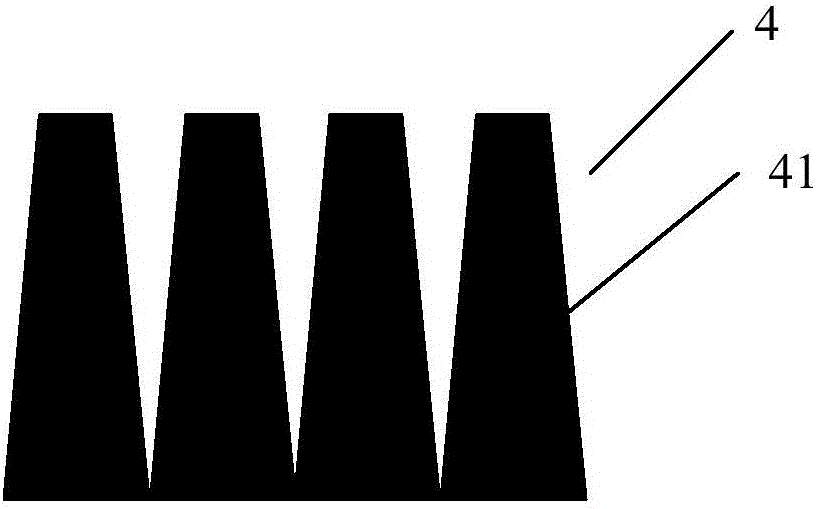

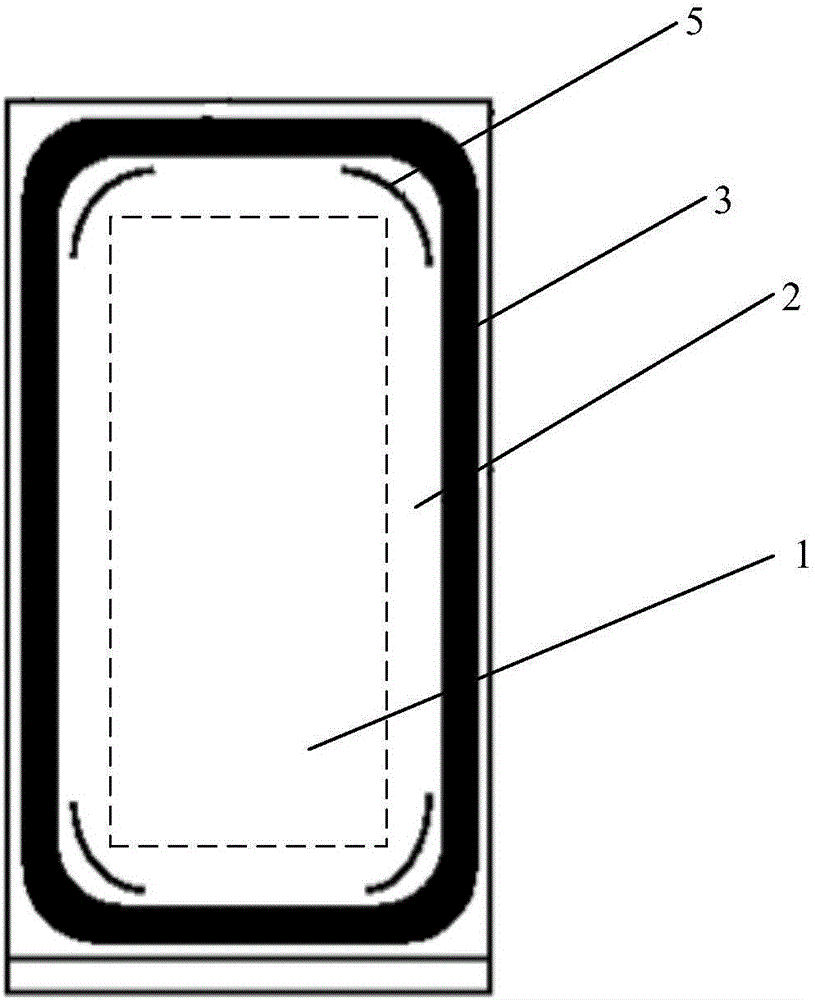

[0025] combine image 3 and 4 As shown, this embodiment provides a display substrate, which includes: a display area 1 and a peripheral area 2 surrounding the display area 1, a sealant 3 is provided in the peripheral area 2, and the display substrate further includes: The retaining wall 5 at the corner of the sealant 3 and close to the display area 1 is an integral structure.

[0026] It should be noted here that the retaining wall 5 refers to a complete structure without gaps. The one-piece structure can be formed by splicing several graphics, but it must be ensured that there is no gap at the splicing position.

[0027] In the display substrate of this embodiment, the retaining wall 5 with an integral structure is used as the retaining wall 5 at the corner of the sealant 3, so it can well prevent the suction material at the corner of the sealant 3 from polluting the display area 1 of the display substrate, and at the same time seal the The glue 3 will not overflow from th...

Embodiment 2

[0035] This embodiment provides a method for preparing a display substrate, wherein the display substrate may be the display substrate described in Embodiment 1. The method for preparing the display substrate includes: forming a retaining wall 5 at the corners of the sealant 3 , preferably each corner, and at a position close to the display area 1 , wherein the retaining wall 5 is an integral structure.

[0036] Specifically, the display substrate may be a color filter substrate or a COA substrate. Hereinafter, taking the display substrate as a color filter substrate as an example, the method for preparing the display substrate of this embodiment will be described. The preparation method of the color filter substrate specifically includes:

[0037] A black matrix (BM; BLACKMATRIX) is formed on the base through processes such as coating, exposure, development, and baking, and a color filter is formed on the display area 1 of the base through processes such as coating, exposure...

Embodiment 3

[0044] This embodiment provides a display device, wherein the display device includes the display substrate of Embodiment 1.

[0045] Of course, the display device in this embodiment can be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0046] Certainly, the display device in this embodiment also has structures such as an outer frame of a conventional display device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com