Method for eliminating bismuth interference in determination of lead content of mineral by EDTA (ethylenediaminetetraacetic acid) volumetric method

A lead content and volumetric method is applied in the field of eliminating bismuth interference, which can solve the problems of bismuth interference, high analysis results, and undiscovered problems, and achieves the effects of eliminating interference, simple method, and meeting the needs of production and analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

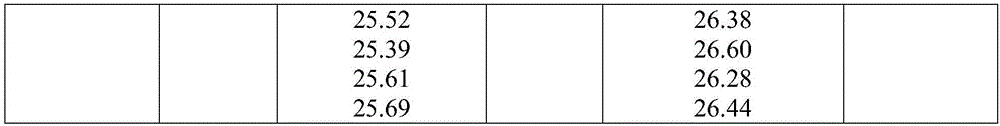

[0058] Embodiment 1: standard sample analysis

[0059] Select national standard sample GBW07172, add 6mg bismuth standard respectively in each part of sample before precipitation lead, adopt method of the present invention (specifically as follows) and analyze sample by method described in GB / T8152.1-2006 respectively:

[0060] The method of the present invention: Weigh 0.20g (accurate to 0.0001g) sample and 0.006g bismuth standard in a 250mL beaker, moisten with a small amount of water, add 15mL hydrochloric acid, cover with a watch glass, heat and dissolve at 120-150°C for 5min Finally, add 5mL of nitric acid, continue to heat until the sample is completely decomposed, then add 6mL of bismuth standard solution, then add 20mL (1+1) sulfuric acid, heat until thick white smoke of sulfur trioxide is emitted, remove and cool, and rinse the surface with a small amount of water Continue to heat the dish and cup wall until smoking, then remove and cool. Then add 50mL of water to it...

Embodiment 2

[0067] Embodiment 2: standard sample analysis

[0068] Select national standard sample GBW07167, add 10mg bismuth standard respectively in each part of sample before precipitation lead, adopt respectively method described in the present invention (specifically as follows) and analyze sample by method described in GB / T8152.1-2006:

[0069] The method of the present invention: Weigh 0.10g (accurate to 0.0001g) sample and 0.010g bismuth standard in a 250mL beaker, moisten with a small amount of water, add 15mL hydrochloric acid, cover with a watch glass, heat and dissolve at 120-150°C for 5min Finally, add 5mL nitric acid, continue to heat until the sample is completely decomposed, then add 20mL (1+1) sulfuric acid, heat until thick white smoke of sulfur trioxide is emitted, remove and cool, rinse the watch glass and cup wall with a small amount of water, and continue heating until smoking, remove and cool. Then add 50mL of water to it, heat and boil to dissolve the soluble salt...

Embodiment 3

[0074] Select the sample A sent by Guilin Jinzeli Mining Co., Ltd., measure the content of bismuth in this sample through the national standard analysis method GB / T15926-2010 to be 4.68%, adopt the method of the present invention (as follows) and press GB / T8152. The method described in 1-2006 analyzes the content of lead in the sample:

[0075] The method of the present invention: Weigh 0.10g (accurate to 0.0001g) sample and 0.010g bismuth standard in a 250mL beaker, moisten with a small amount of water, add 15mL hydrochloric acid, cover with a watch glass, heat and dissolve at 120-150°C for 5min Finally, add 5mL nitric acid, continue to heat until the sample is completely decomposed, then add 20mL (1+1) sulfuric acid, heat until thick white smoke of sulfur trioxide is emitted, remove and cool, rinse the watch glass and cup wall with a small amount of water, and continue heating until smoking, remove and cool. Then add 50mL of water to it, heat and boil to dissolve the solubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com