Vertical copper sealing rod and horizontal rubber waterstop connecting method

A technology of rubber waterstop and connection method, which is applied in water conservancy projects, sea area projects, construction, etc., to achieve the effects of convenient production, stable connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

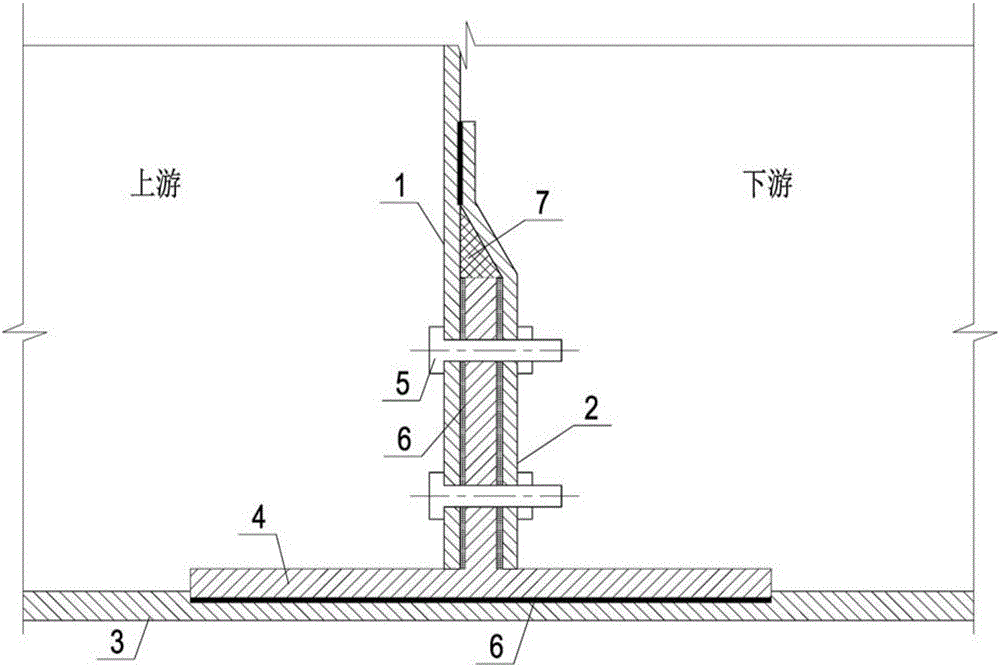

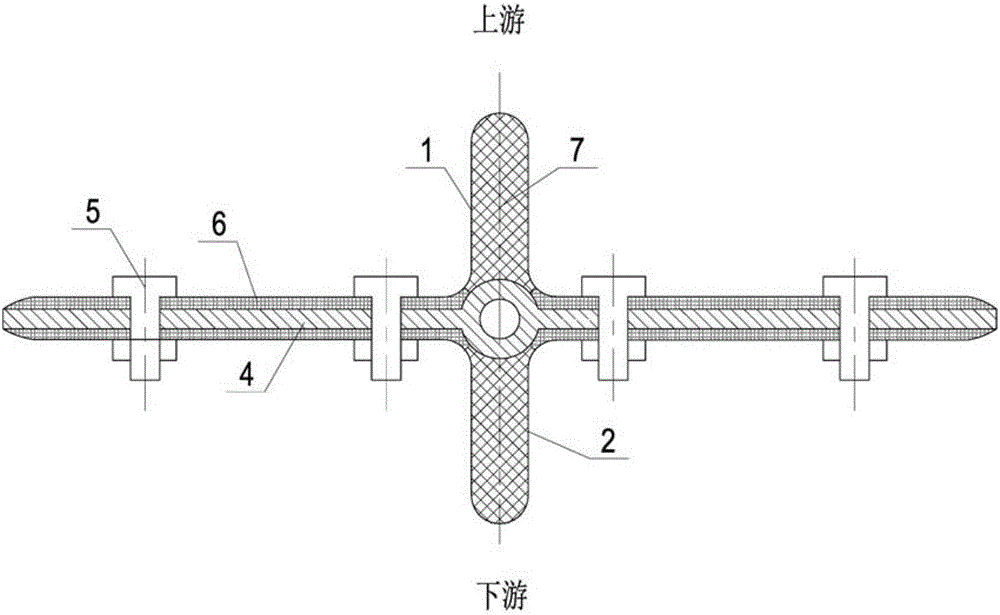

[0015] Such as figure 1 , 2 As shown, the connection method of the vertical copper waterstop of the present invention and the horizontal rubber waterstop comprises the following steps:

[0016] 1) Weld a section of external copper waterstop 2 at a certain distance from the bottom of the vertical copper waterstop 1, so that an installation groove is formed between the external copper waterstop 2 and the vertical copper waterstop 1, and the external copper waterstop The bottom end of the strip 2 is level with the bottom end of the vertical copper waterstop strip 1;

[0017] 2) Polish the bottom surface of the horizontal rubber waterstop 3 and the rubber waterstop T-joint 4 smoothly to expose fresh rubber, clean the surface, and use neoprene 6 to seal the rubber waterstop 3 and the rubber waterstop T Paste the bottom of joint 4 together;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com