Method for manufacturing box counterweight of crane without surface bulges

A technology of cranes and counterweights, which is applied in the direction of cranes, etc., can solve the problems of bulging on the counterweight surface, high cost, and affecting the balance of the crane, and achieve the effects of preventing surface bulging, reducing costs, and facilitating on-site production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

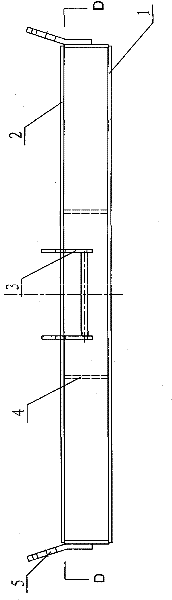

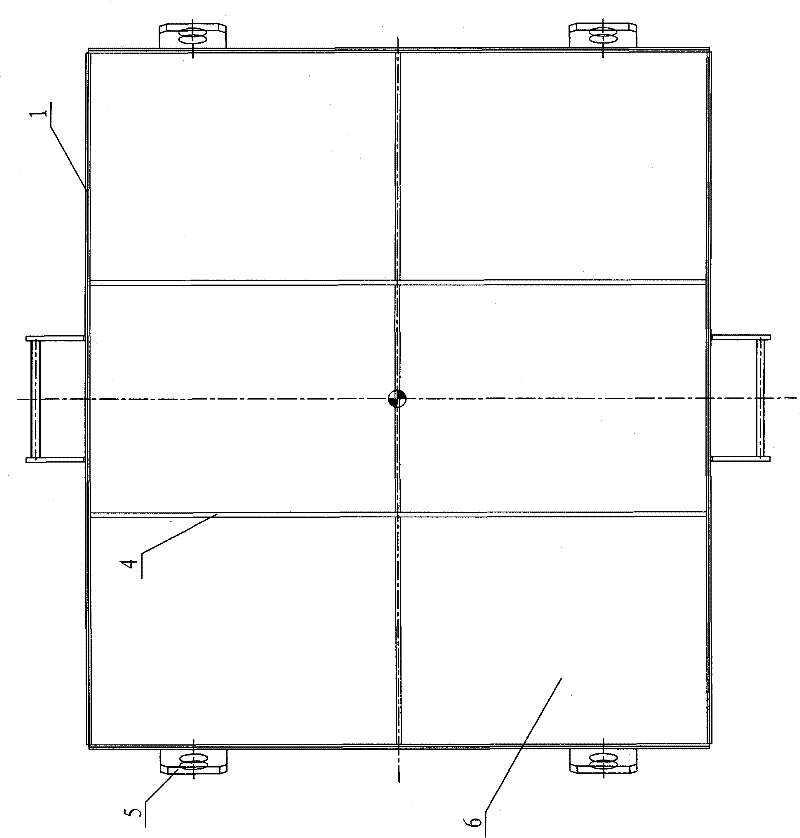

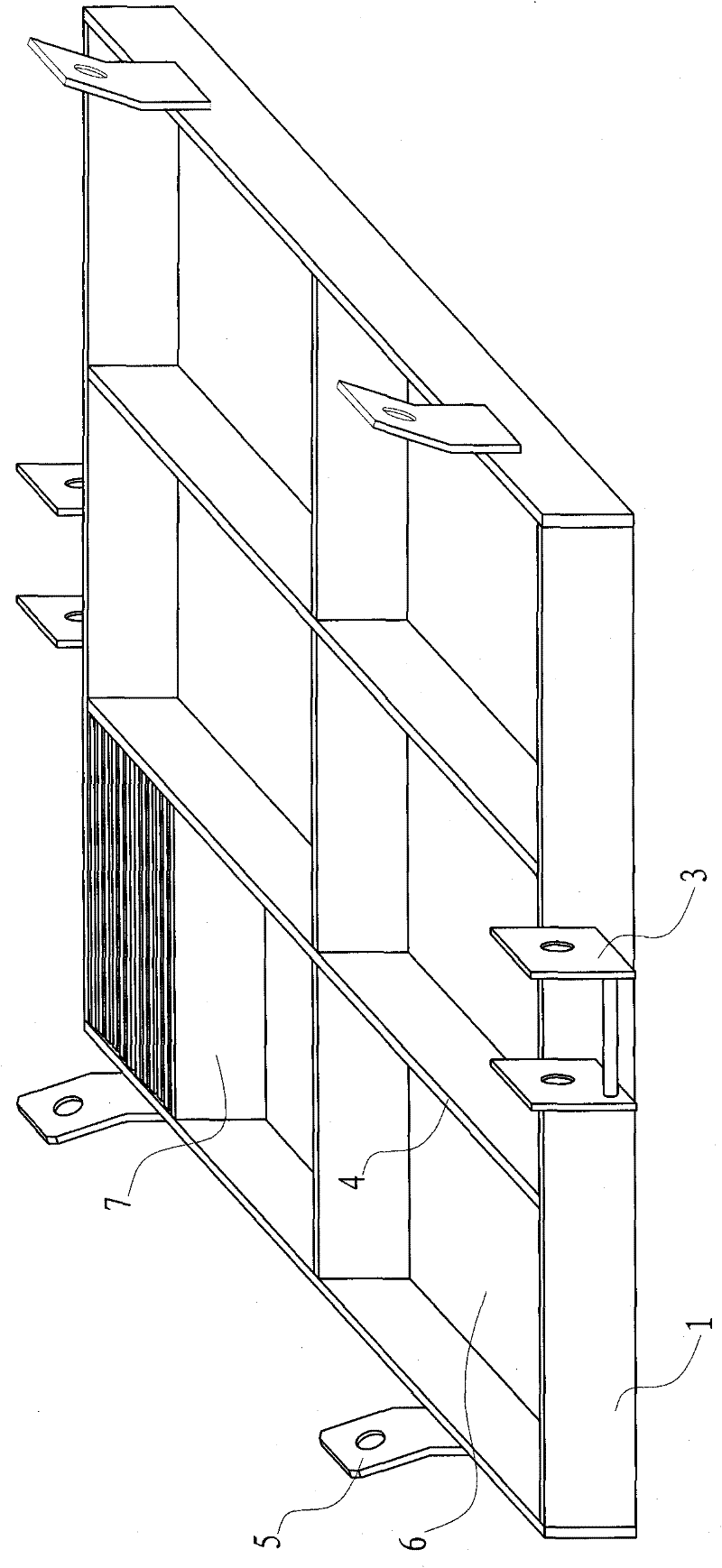

[0014] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, see Figure 1 to Figure 3 :

[0015] A kind of preparation method of the crane box-type counterweight that prevents surface bulging according to the present invention comprises the following steps:

[0016] (a) According to the size specified for the counterweight box, it is welded and assembled to form a box body 1 structure with a hollow interior and an opening on the end face. After welding, a kerosene penetration test must be performed on the welds around the outer frame to ensure that the welds are free. Leakage phenomenon; welding lug 3 and side lug 5 on the outside of box body 1 for easy movement.

[0017] (b) Weld the reinforcing rib plate 4 inside the counterweight box body 1 that has passed the step (a) test without leakage. The purpose of welding the reinforcing rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com