Preparation method of quantum dot film

A technology of thin film preparation and quantum dots, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of high technical requirements, quantum dot damage, failure to protect quantum dots, etc., and achieve the preparation process Simple and convenient, reduce production cost, reduce the effect of technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

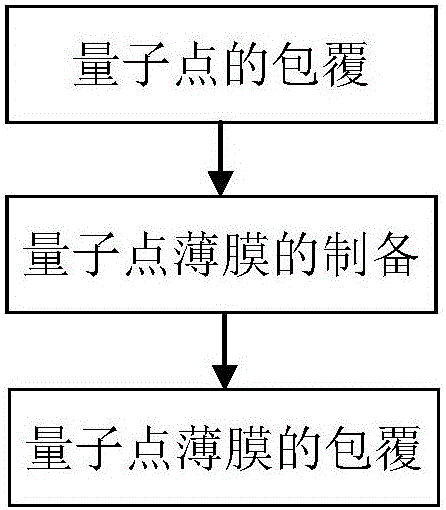

[0038] Such as figure 1 As shown, a method for preparing a quantum dot film provided by the embodiment of the present invention mainly includes three steps: coating of quantum dots, preparation of quantum dot film and coating of quantum dot film. One-time coating, through the coating of quantum dots to ensure that the quantum dots are not oxidized, then coat the coated quantum dots into the film, and finally coat the film coated with quantum dots again, through the graded coating way, to overcome the water / oxygen transmission rate directly coated with a layer of protective film on the quantum dot powder cannot reach 10 -5 A matter of magnitude.

[0039] Each step will be described in detail below.

[0040] 1) Coating of quantum dots: use atomic layer deposition technology to deposit nanometer or submicron thickness metal oxide films on the surface of quantum dots, such as zinc oxide, aluminum oxide, titanium oxide, and coat quantum dots to ensure that quantum dots do not Ox...

Embodiment 1

[0078] This embodiment takes the preparation of aluminum oxide film as an example to further illustrate the preparation method of the present invention, which includes the following steps:

[0079] 1) Quantum dot coating

[0080] 1.1) Spread 3g of quantum dots on the filter screen of the powder holder, then put the powder holder into the cavity of the atomic layer deposition reactor, cover the cavity, ensure that the cavity is clean, and evacuate to 1-10PaPa;

[0081] 1.2) Heating the cavity so that the temperature of the fluidization area used for pre-dispersing the quantum dot powder in the cavity reaches 80°C, and during the heating process, the fluidization gas is continuously introduced at a flow rate of 100 standard milliliters per minute to pre-disperse the quantum dots;

[0082] 1.3) When the temperature in the chamber reaches 120°C, an atomic layer deposition reaction is completed, including:

[0083] Pass deionized water into the cavity as the first precursor to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com