Blast furnace flush slag water waste heat utilization system and method

A blast furnace slag flushing water and slag flushing water technology, which is applied in the field of blast furnaces, can solve problems such as equipment damage and corrosion, and achieve the effects of saving manufacturing costs, high heat exchange efficiency, and strong resistance to erosion and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

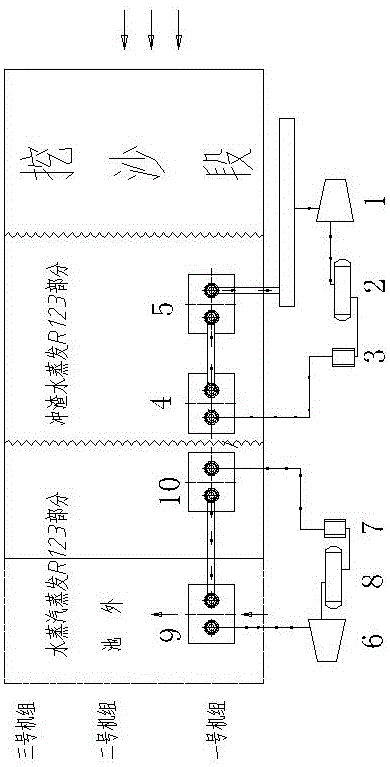

[0020] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the waste heat utilization system of blast furnace slag flushing water described in this embodiment includes a sand dredging section, a slag flushing pool, and an outer part connected in sequence. Steam evaporation mechanism, the slag flushing water evaporation mechanism includes a slag flushing water screw expansion power machine 1, a slag flushing water condenser 2, a slag flushing water liquid storage device 3, an immersion preheater 4, and a dry evaporator 5, Among them, the immersion preheater 4 and the dry evaporator 5 are installed in the slag washing pool, and the outlet of the immersion preheater 4 is connected to the inlet of the dry evaporator 5, and the outlet of the dry evaporator 5 is connected to the slag washing water screw The expansion power machine 1 is connected, the slag wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com