Concrete precast block, assembly interlocking apron and construction method of assembly interlocking apron

A technology of concrete and prefabricated blocks, which is applied in the construction of interlocking shields, concrete prefabricated blocks, and the field of assembling interlocking shields, can solve the problem of reducing the cross-sectional area of water, high water content of rock and soil, affecting flooding and flooding. Overcurrent and other problems, to achieve the effect of convenient construction, remarkable flexibility and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

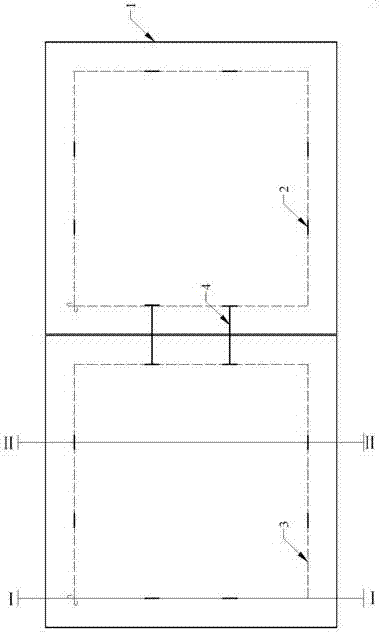

[0019] Embodiment 1; as figure 1 , image 3 and Figure 4 Shown: a kind of concrete prefabricated block body provided by the present invention; It is rectangular concrete prefabricated block body 1, and rectangular concrete prefabricated block body 1 is provided with reinforcing steel bar 3 around, and reinforcing steel bar 3 is provided with a plurality of protruding block bodies Reinforcement connection holes 2 on the surface.

[0020] The concrete prefabricated block 1 is made, and after the reinforced steel bar 3 provided with the steel bar connecting hole 2 is set in the mold, it is formed by one-time pouring of concrete.

[0021] Further, the reinforcement connection holes 2 are evenly arranged around the upper surface of the prefabricated concrete block 1, usually four to eight locations, and eight in this embodiment; the reinforcement connection holes 2 are parallel to the edge of the concrete prefabricated block, and the reinforcement connection holes The distance ...

Embodiment 2

[0024] Embodiment 2; as figure 2 , image 3 and Figure 4 Shown: an assembled chain-type apron; it is composed of a large number of concrete prefabricated blocks 1 laid on the bottom of the river ditch or the bottom of the agricultural canal 1 and fixedly connected to each other ( figure 2 Shown are two concrete prefabricated blocks 1) fixedly connected to each other on the left and right. The connecting steel bars 4 pass through the steel bar connecting holes 2 of the two adjacent prefabricated concrete blocks 1 to fix and connect the two adjacent prefabricated concrete blocks 1 . The upper surface of the prefabricated concrete block 1 is substantially flush with the original bottom 6 of the river ditch bed or agricultural canal.

Embodiment 3

[0025] Example 3; see image 3 and Figure 4 , a construction method for assembling chain-type aprons, which is carried out according to the following steps: firstly excavate and level the original bottom of the river ditch bed or agricultural canal to be protected 6, the excavation depth is the thickness H of the concrete prefabricated block, and the longitudinal ratio is maintained The drop is basically unchanged; then, from the upstream, the concrete prefabricated block 1 is laid on the river bed or the bottom 6 of the agricultural canal, the steel bar connection hole 2 is located on the top surface, the joints of adjacent blocks are tight, and the tops are flush; see figure 2 , and finally use the connecting steel bar 4 to connect the adjacent steel bar connecting holes 2 one by one to form an assembly chain type apron. The upper surface of the prefabricated concrete block 1 is substantially flush with the original bottom 6 of the river ditch bed or agricultural canal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com