Baijiu fermenting tank and building method

A construction method and a fermentation tank technology, which are applied in building structure, biochemical equipment and methods, construction, etc., can solve the problems of large influence on distillation, easy aging of pit mud, etc., so as to improve the wine yield and highlight the wine body. style, the effect of resolving fermentation failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

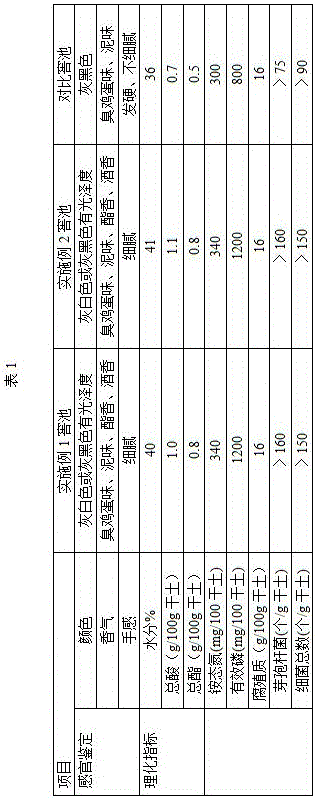

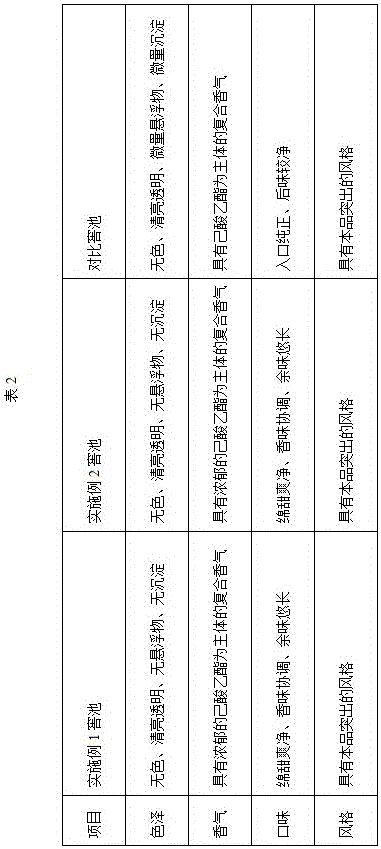

[0050] The preparation method of the functional bacteria culture solution in the embodiment is an existing method, specifically: half of the caproic acid bacteria separated from the old pit mud are gradually expanded and cultivated in a plastic bucket of 10 kg in the improved simplified pasteurized synthetic medium , and the other half use the old pit mud of our factory as the provenance, in the culture medium containing 10% of yellow water, 10% of grain grains from retorts, 5% of Daqu, and the pH value is adjusted to 5.0-6.0 with lime water, and also step by step. Expand to a plastic bucket of 10kg. These two seed plastic barrels were inoculated into a 250-kg pottery jar, and the culture medium was changed to contain 18% yellow water, 10% rice grains, 5% Daqu, and 5% fermented mud, and the pH value was adjusted with ammonium carbonate. 5.0—5.5.

[0051] The pit mud culture method is an existing method, specifically: the pit mud adopts viscous yellow mud, pit mud, and high-qu...

Embodiment 1

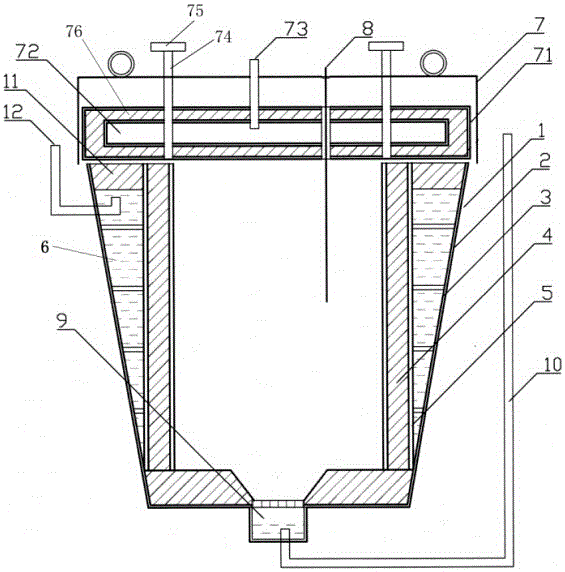

[0053] (1) New cellar

[0054] a. Digging cellar pool: According to the characteristics of the terrain, select a place with good terrain and environment to dig and build an inverted trapezoidal conical cellar pool. The upper port of the cellar pool is 3.5m long and 1.7m wide. The lower port is 3.2m long, 1.4m wide, and the cellar is 1.8m deep. The angle between the inner surface of the cellar wall and the bottom of the cellar is 5 degrees; the thickness of the mud layer at the bottom of the cellar is 20-30cm; The size is 0.8m in length, 0.4m in width and 0.4m in depth, and the yellow water pool is located in the lower center of the cellar. The inner surface of the yellow pool is made of concrete with a thickness of 3cm.

[0055] c. Pre-embedded U-shaped pipe: pre-embedded stainless steel unequal arm ∪-shaped pipe, using a 304 stainless steel elbow with a diameter of 60 mm, one end is pre-embedded at the bottom of the yellow pool, the height of the nozzle from the bottom of th...

Embodiment 2

[0066] (1) New cellar

[0067] a. Digging cellar pool: According to the characteristics of the terrain, select a place with better terrain and environment to dig and build an inverted trapezoidal conical cellar pool. The upper port of the cellar pool is 3.8m long and 1.9m wide. The lower plane is 3.5m long, 1.6m wide, and the depth of the pit is 2.0m. The angle between the inner surface of the pit wall and the bottom of the pit is 10 degrees; the thickness of the mud layer at the bottom of the pit is 20-30cm;

[0068] b. Excavate and build a yellow water pool: the size is 1m long, 0.6m wide, and 0.6m deep. The yellow water pool is located in the lower center of the cellar. The inner surface of the yellow pool is made of concrete with a thickness of 5cm.

[0069] c. Pre-embedded stainless steel unequal arm ∪-shaped pipe, using a 304 stainless steel elbow with a diameter of 60 mm, one end is pre-buried at the bottom of the yellow pool, the height of the pipe mouth from the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com