Wear-resistant electrician bag for power systems

A technology for power systems and electrical bags, applied in applications, clothing, accessories, etc., can solve problems such as affecting safe electricity consumption, electrical bags are susceptible to moisture, and the service life is not long, so as to extend the scorch time, improve processing safety, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

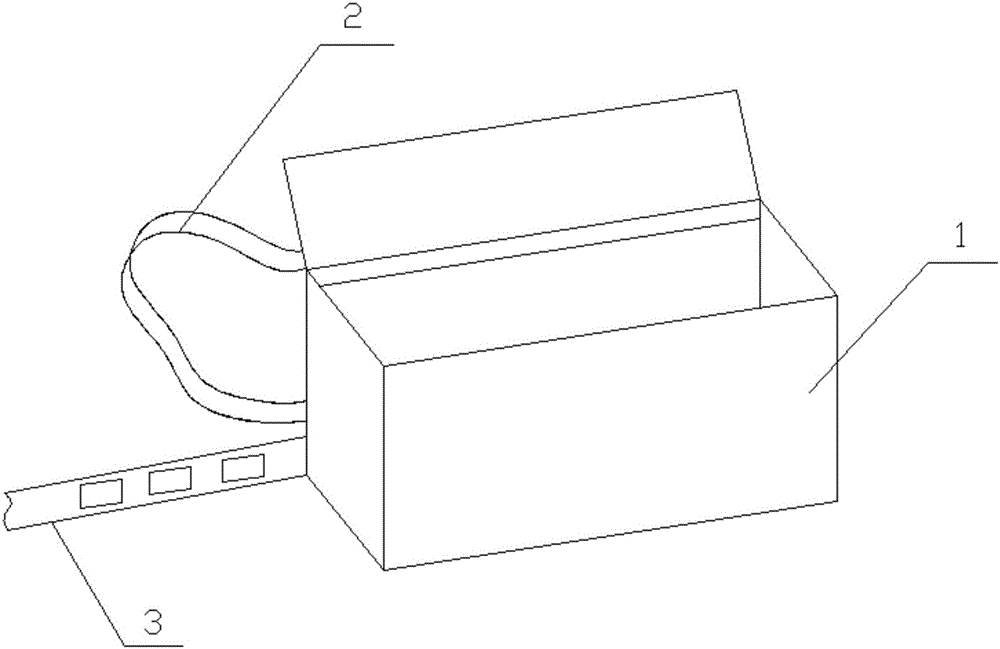

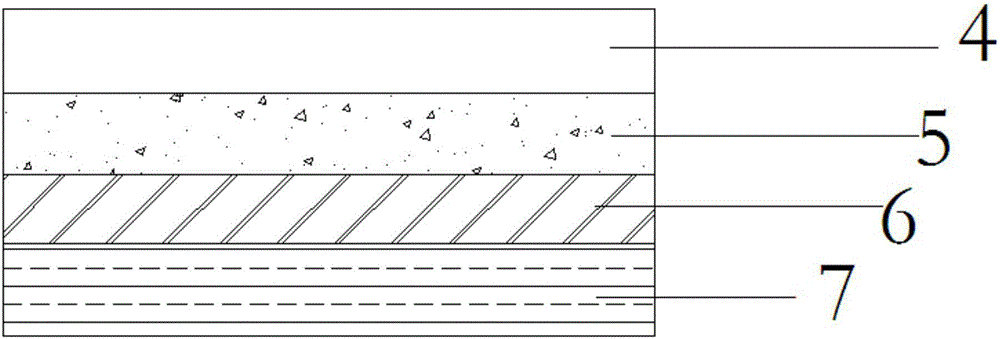

[0031] A wear-resistant electrician's bag for a power system, the structure of which is as follows figure 1 , figure 2 As shown, it includes a bag body 1, a shoulder strap 2 and a waist belt 3. A circle of insulating frames is arranged along the opening of the bag body. The shoulder straps 2 are connected to both sides of the bag body 1. side, the waist belt is connected to the other side of the bag body through Velcro, and the bag body 1 includes an inner wear-resistant layer 4, a non-woven fabric layer 5, a waterproof layer 6 and an outer wear-resistant layer 7 from the inside to the outside , the inner wear-resistant layer 4 is made of beef tendon thin layer, the waterproof layer 6 is a polyvinyl chloride waterproof layer, and the thickness of the outer wear-resistant layer 7 is 2mm, and the raw material components of the outer wear-resistant layer are as follows, all in parts by weight:

[0032] 52 parts of styrene-butadiene rubber, 28 parts of neoprene rubber, 25 parts ...

Embodiment 2

[0040] With the electrical bag described in embodiment 1, the difference is that,

[0041] The raw material components of the outer wear-resistant layer are as follows, all in parts by weight:

[0042] 58 parts of styrene-butadiene rubber, 32 parts of neoprene rubber, 23 parts of fluoroether rubber, 5 parts of graphene, 5 parts of phenolic resin, 698 parts of silane coupling agent Si, 15 parts of semi-reinforced furnace black, 12 parts of calcined clay, magnesium powder 4 parts, nanomolybdenum disulfide (MoS 2 ) 7 parts, 8 parts of phenylenediamine derivative anti-aging agent, 5 parts of zinc oxide, 4 parts of dithiotetrabutylthiuram.

[0043] The above-mentioned material for the outer wear-resistant layer is prepared according to the following method, and the steps are as follows:

[0044] (1) Molybdenum disulfide is added to N-methylpyrrolidone, and molybdenum disulfide suspension is obtained after ultrasonic stripping for 2 hours; the mass volume ratio of molybdenum disul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com