A preparation method of low molecular weight barley β-glucan with auxiliary hypoglycemic effect

A low-molecular-weight, glucan technology, which is applied in the direction of food ingredients, food ingredient functions, fermentation, etc., can solve the problems of high molecular weight products, research and confirmation of the hypoglycemic effect of barley β-glucan, and achieve convenient application , good effect of auxiliary hypoglycemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

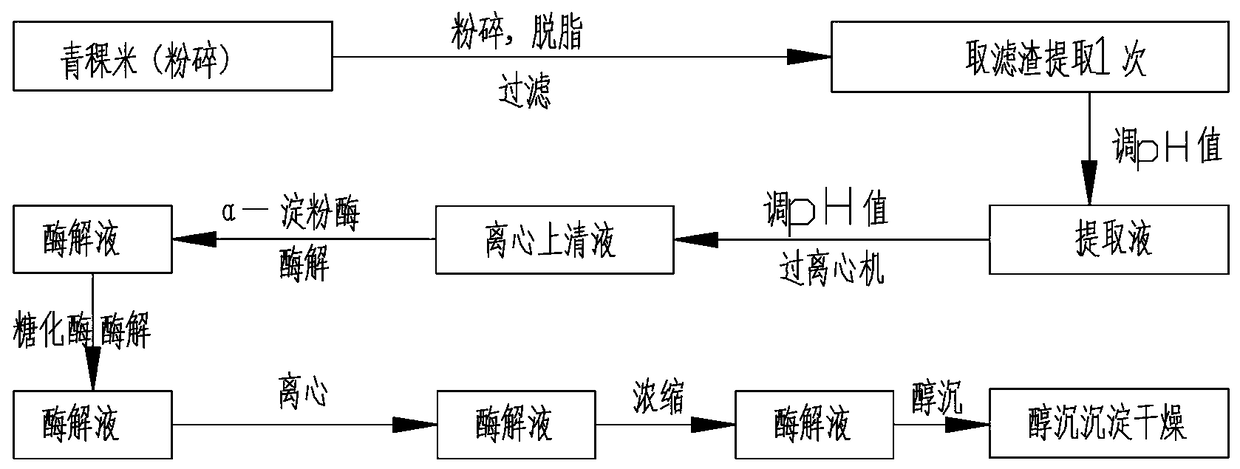

[0026] see figure 1 , (1) raw material processing: get dry highland barley rice 60kg, be ground into 50 purpose coarse powders after weighing, drop in the extraction tank;

[0027] (2) Extraction: Stir 180L of pure water, put it into the extraction tank, replenish the water to 540L, adjust the pH to 10.0 with saturated sodium carbonate solution, stir and extract at 75°C for 1.5 hours; after the extraction is completed, pour the extract into the holding cylinder , adjusting the pH of the extract to 4.5 with a hydrochloric acid solution with a mass fraction of 10%, stirring evenly, and standing overnight to cool;

[0028] (3) Centrifugation: Centrifuge with a three-legged desktop centrifuge at a speed of 3000r / min, and merge the centrifuged supernatant;

[0029] (4) Enzymatic hydrolysis: ① Amylase enzymatic hydrolysis: add 240g α-amylase to the supernatant, activate at 60°C for 30 minutes, adjust the pH to 5 with saturated sodium carbonate solution, and stir at 50°C for 60 minu...

Embodiment 2

[0036] (1) raw material processing: get dry highland barley rice 30kg, weigh and pulverize into 20 mesh coarse powder, drop into extraction tank;

[0037] (2) Extraction: Stir 90L of pure water, put it into the extraction tank, replenish the water to 270L, adjust the pH to 9.0 with saturated sodium carbonate solution, stir and extract at 75°C for 1.5 hours; after the extraction is completed, pour the extract into the holding cylinder , adjusting the pH of the extract to 4.5 with a hydrochloric acid solution with a mass fraction of 10%, stirring evenly, and standing overnight to cool;

[0038] (3) Centrifugation: centrifuge with a three-legged desktop centrifuge at a speed of 1500r / min, and merge the centrifuged supernatant;

[0039](4) Enzymatic hydrolysis: ① Amylase enzymatic hydrolysis: add 60g α-amylase to the supernatant, activate at 50°C for 30 minutes, adjust the pH to 5.0 with saturated sodium carbonate solution, and stir at 50°C for 40 minutes; ② Glucoamylase enzymatic...

Embodiment 3

[0045] (1) raw material processing: get dry highland barley rice 50kg, weigh and pulverize into 30 purpose coarse powder, drop into extraction tank;

[0046] (2) Extraction: Stir 150L of pure water, put it into the extraction tank, add water to 450L, adjust the pH to 10.0 with saturated sodium carbonate solution, stir and extract at 85°C for 2 hours; after the extraction is completed, pour the extract into the holding cylinder , adjusting the pH of the extract to 6.5 with a hydrochloric acid solution with a mass fraction of 10%, stirring evenly, and standing overnight to cool;

[0047] (3) Centrifugation: Centrifuge with a three-legged desktop centrifuge at a speed of 3000r / min, and merge the centrifuged supernatant;

[0048] (4) Enzymatic hydrolysis: ① Amylase enzymatic hydrolysis: add 150g α-amylase to the supernatant, activate at 60°C for 30 minutes, adjust the pH to 6.5 with saturated sodium carbonate solution, and stir at 60°C for 50 minutes; ② Glucoamylase enzymatic hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com