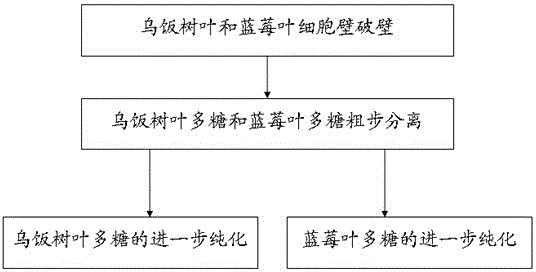

Separation and purification method for Vaccinium bracteatum Thunb. leaf polysaccharide and blueberry leaf polysaccharide

A technology of separation and purification of leaves of black rice, applied in the directions of digestive system, metabolic diseases, antiviral agents, etc., to achieve the effect of promoting development, no drug residues, and enhancing immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 (Isolation and Purification of Polysaccharides from Black Rice Leaf)

[0021] 1) The cell wall of the leaves of Wufan tree is broken. With black rice leaves as raw material. First, take 10Kg of fresh black rice leaves and clean them; secondly, use the ultrasonic crushing method to break the cell wall of the leaves. Purified water with a weight ratio of 1:1 enters the colloid mill for grinding, selects the grinding fineness of 10 μm, and grinds 5 times; finally, freezes the ground product at -15°C for 1 hour, and then puts it in 80°C water to heat up suddenly It melts and heats up for 15 minutes, and after the ground product is cooled to room temperature, it is frozen at -15°C for 1 hour, and this is repeated 3 times to obtain the broken cell wall liquid of the leaves of the black rice plant.

[0022] 2) Coarse separation of polysaccharides from leaves of black rice leaves. First, using a KOH solution with a weight concentration of 1%, according to the sta...

Embodiment 2

[0024] Embodiment 2 (isolation and purification of blueberry leaf polysaccharide)

[0025] 1) The cell wall of the blueberry leaf is broken. Made with blueberry leaves. First, take 10Kg of fresh blueberry leaves and clean them; secondly, use the ultrasonic crushing method to break the cell wall of the leaves. Purified water with a ratio of 1:1 enters the colloid mill for grinding, selects the grinding fineness of 10 μm, and grinds 5 times; finally, freezes the ground product at -15°C for 1 hour, then puts it in 80°C water and suddenly heats it up to make it Melt, heat up for 15 minutes, after the ground product is cooled to room temperature, put it into -15°C environment and freeze it for 1 hour, and repeat this process 3 times to obtain the blueberry leaf broken cell wall liquid.

[0026] 2) Coarse separation of blueberry leaf polysaccharides. First, using a KOH solution with a weight concentration of 1%, according to the standard that the mass ratio of the KOH solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com