Method for preparing 4-chlorine-2-(trifluoroacetyl) aniline hydrochloride hydrate

A technology of trifluoroacetylphenyl and trifluoroacetyl, which is applied in the field of compound preparation and can solve the problem of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

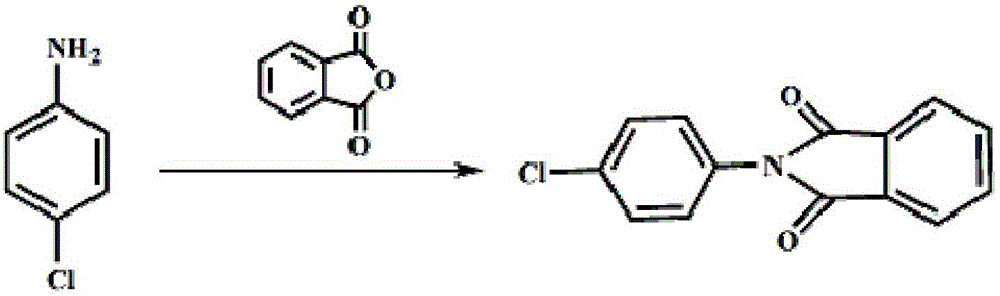

[0019] A method for preparing 4-chloro-2-(trifluoroacetyl)aniline hydrochloride hydrate, specifically comprising the steps:

[0020] ①Synthesis of 4-chloro-N-phthalic anilide: Add 12.8g of p-chloroaniline, 102mL of toluene and 16.3g of phthalic anhydride to the reactor connected to the water separator, heat up to 110-120°C, Reflux for 1.5 hours, TLC monitoring, the reaction is complete, lower the temperature to 30-35°C, add 50mL of water, separate layers, wash the toluene layer with 100mL of water twice, cool down to -5-0°C, stir for 2 hours, suction filter, filter The cake was rinsed with an appropriate amount of water, drained, and the solid was vacuum-dried at 70°C to obtain 23.2 g of 4-chloro-N-phthalanilide, with a yield of 95.1% and a content of 99.2%.

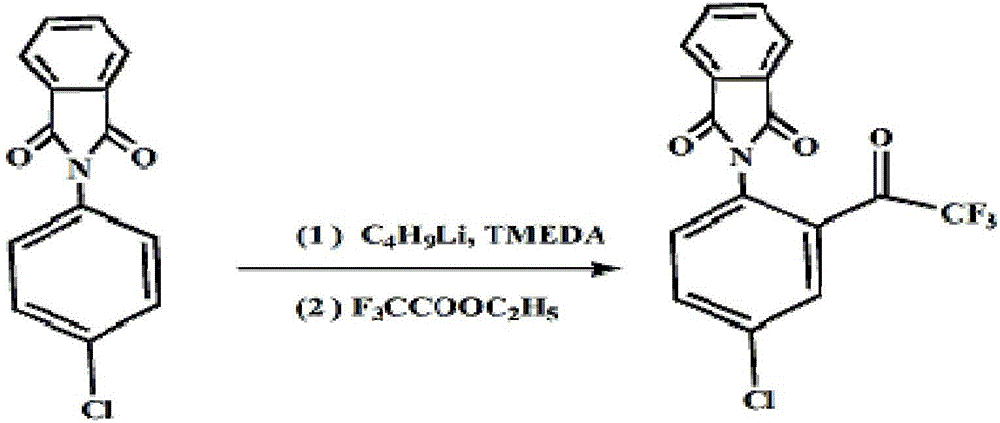

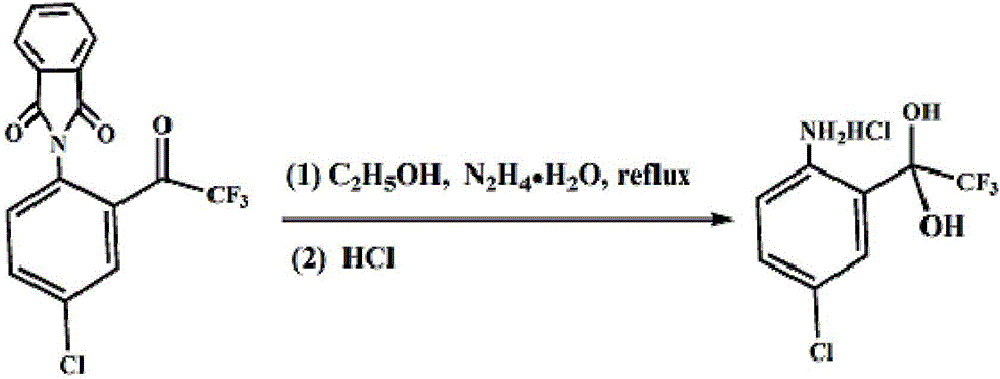

[0021] ② Synthesis of N-(4-chloro-2-trifluoroacetylphenyl)-phthalamide: In the reactor, under the protection of nitrogen, add 25.8g of 4-chloro-N-phthalamide , 258mL of methyl tert-butyl ether, 11.6g of tetramethylethyl...

Embodiment 2

[0024] A method for preparing 4-chloro-2-(trifluoroacetyl)aniline hydrochloride hydrate, specifically comprising the steps:

[0025] ①Synthesis of 4-chloro-N-phthalic anilide: Add 12.8g of p-chloroaniline, 102mL of toluene and 14.8g of phthalic anhydride to the reactor connected to the water separator, heat up to 110-120°C, Reflux for 1.5 hours, TLC monitoring, the reaction is complete, lower the temperature to 30-35°C, add 50mL of water, separate layers, wash the toluene layer with 100mL of water twice, cool down to -5-0°C, stir for 2 hours, suction filter, filter The cake was rinsed with an appropriate amount of water, drained, and the solid was vacuum-dried at 70°C to obtain 21.9 g of 4-chloro-N-phthalanilide, with a yield of 90% and a content of 99.0%.

[0026] ② Synthesis of N-(4-chloro-2-trifluoroacetylphenyl)-phthalamide: In the reactor, under the protection of nitrogen, add 25.8g of 4-chloro-N-phthalamide , 258mL of methyl tert-butyl ether, 11.6g of tetramethylethylen...

Embodiment 3

[0029] A method for preparing 4-chloro-2-(trifluoroacetyl)aniline hydrochloride hydrate, specifically comprising the following steps, 1. the synthesis of 4-chloro-N-phthalanilide: in a water separator connected Add 12.8g of p-chloroaniline, 51mL of toluene, and 16.3g of phthalic anhydride into the reactor, raise the temperature to 110-120°C, reflux for 1.5 hours, monitor by TLC, after the reaction is complete, cool down to 30-35°C, add 50mL of water, and divide layer, the toluene layer was washed twice with 100 mL of water, cooled to -5 ~ 0 ° C, stirred for 2 hours, filtered with suction, the filter cake was rinsed with an appropriate amount of water, and dried, and the solid was vacuum-dried at 70 ° C to obtain 4- Chloro-N-phthalanilide 19.5g, yield 80%, content 98.5%.

[0030] ② Synthesis of N-(4-chloro-2-trifluoroacetylphenyl)-phthalamide: In the reactor, under the protection of nitrogen, add 25.8g of 4-chloro-N-phthalamide , 258mL of methyl tert-butyl ether, 11.6g of tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com