Fluorine-gypsum-based machine-spraying thermal insulation mortar and preparation method thereof

A technology of thermal insulation mortar and fluorine gypsum, applied in the field of composite thermal insulation materials, can solve the problems of poor mortar cohesion, slow hydration process, poor water retention, etc., and achieve the effects of fast construction speed, low shrinkage deformation, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

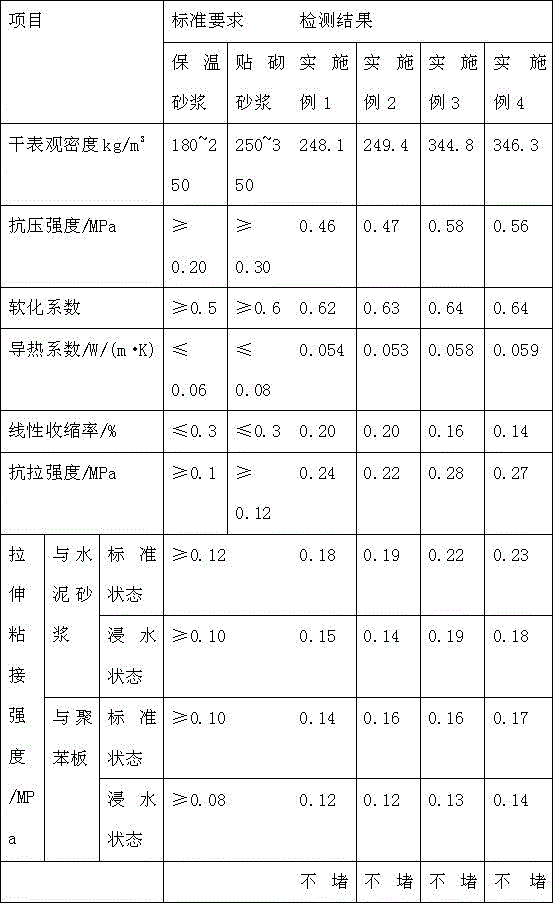

Embodiment 1

[0017] By weight, the specific surface area is 350m 2 / kg of fluorine gypsum powder 79 parts, quicklime 4 parts, cement 6 parts, the specific surface area is 360m 2 10 parts / kg of slag powder, 1 part of thixotropic lubricant, 0.8 parts of ferrous sulfate, 0.1 parts of water retaining agent, viscosity of 100,000 mpa.s, 0.2 parts of α-starch, 0.2 parts of polyvinyl alcohol, vinyl acetate- Put 0.8 parts of ethylene copolymer latex powder into a multifunctional dry powder mixer, mix and stir for 10 minutes to obtain a uniformly mixed thermal insulation mortar masterbatch, then put the masterbatch into a mortar mixer, add 70 parts of water and mix for 3 minutes, the mixer speed 60 rpm, then 1.9 parts of EPS granules were added, the mixer was rotated at 60-80 rpm, and stirred for 5 minutes to obtain fluorogypsum-based machine-sprayed thermal insulation mortar.

Embodiment 2

[0019] By weight, the specific surface area is 350m 2 / kg of fluorine gypsum powder 73 parts, quicklime 5 parts, cement 6 parts, the specific surface area is 360m 2 / kg of slag fine powder 15 parts, thixotropic lubricant 1 part, ferrous sulfate 1 part, water retaining agent 0.2 part, viscosity is 100,000 mpa.s, α-starch 0.3 part, polyvinyl alcohol 0.3 part, vinyl acetate- Put 0.6 parts of ethylene copolymer latex powder into a multifunctional dry powder mixer, mix and stir for 10 minutes to obtain a uniformly mixed thermal insulation mortar masterbatch, then put the masterbatch into a mortar mixer, add 70 parts of water and mix for 3 minutes, the mixer speed 60 rpm, then 1.9 parts of EPS granules were added, the mixer was rotated at 60-80 rpm, and stirred for 5 minutes to obtain fluorogypsum-based machine-sprayed thermal insulation mortar.

Embodiment 3

[0021] By weight, the specific surface area is 350m 2 / kg of fluorine gypsum powder 70 parts, quicklime 6 parts, cement 8 parts, the specific surface area is 360m 2 15 parts / kg of slag powder, 1 part of thixotropic lubricant, 1.2 parts of ferrous sulfate, 0.2 parts of water retaining agent, viscosity of 100,000 mpa.s, 0.2 parts of α-starch, 0.4 parts of polyvinyl alcohol, vinyl acetate- Put 0.6 parts of ethylene copolymer latex powder into a multifunctional dry powder mixer, mix and stir for 10 minutes to obtain a uniformly mixed thermal insulation mortar masterbatch, then put the masterbatch into a mortar mixer, add 70 parts of water and mix for 3 minutes, the mixer speed 60 rpm, and then add 1.0 parts of EPS granules, the mixer speed is 60-80 rpm, and stir for 5 minutes to obtain fluorogypsum-based machine-sprayed thermal insulation mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com