Gum for vetrified bricks, preparation method for gum and construction method

A construction method and vitrified brick technology, which is applied in the field of vitrified brick adhesive and its preparation, can solve the problems of unsatisfactory application effect, poor pasting effect, low interface agent strength, etc., and achieve high cost performance and cross-linked network structure The effect of compactness and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

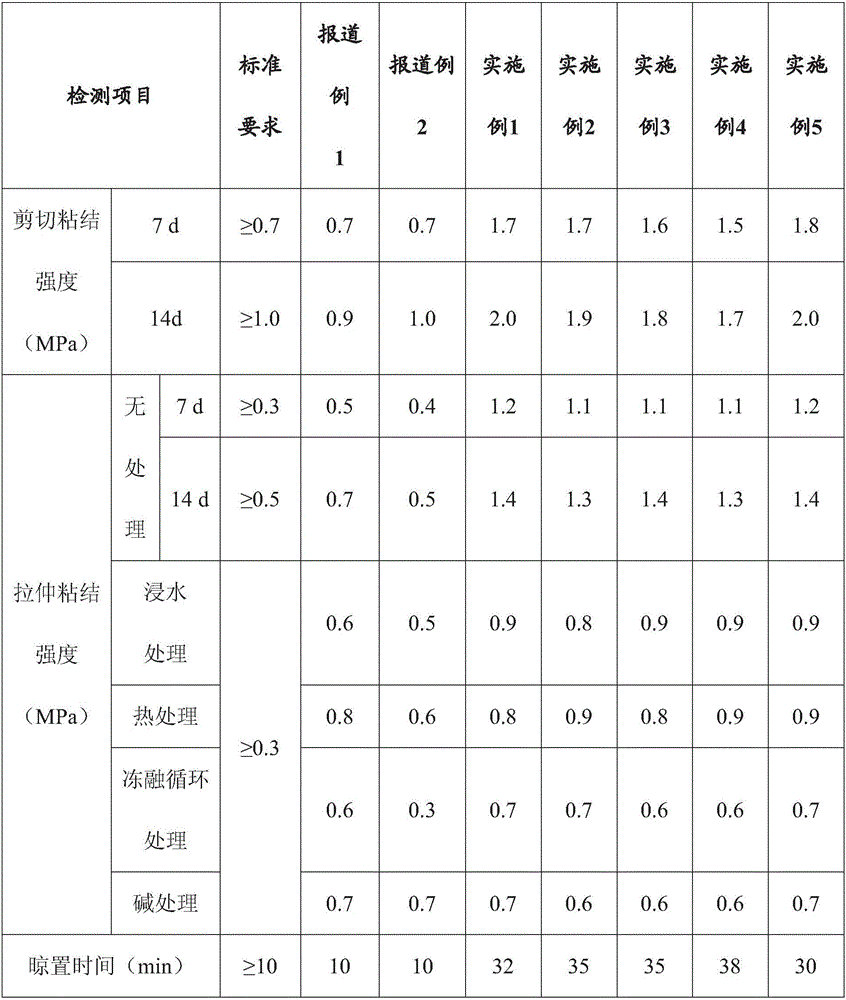

Examples

Embodiment 1

[0029] 1) Weigh each component according to the following percentage by weight: styrene-butadiene emulsion 42%, styrene-acrylic emulsion 34%, water 20%, reinforcing agent 2.0%, anti-mold agent 0.5%, defoamer 1.0% and water repellent 0.5% %, and then mix and stir the weighed components to make liquid material components.

[0030] 2) each component is weighed by the following percentage by weight: Portland cement 48%, river sand 48%, cellulose ether 0.5%, water reducer 0.5%, organosilicon powder 1.5% and nano silicon oxide 1.5%, then Mix and stir the weighed components to make powder components.

[0031] 3) The prepared liquid component and the powder component are mixed and stirred at a weight ratio of 1:2.5 to form vitrified tile adhesive.

[0032] 4) The construction of vitrified tile back glue: put the vitrified tile flat on the ground, first use a hard brush, wire brush, semi-dry towel and other tools to clean off the attachments on the vitrified tile adhesive surface; the...

Embodiment 2

[0034] 1) Each component is weighed according to the following percentage by weight: 40% styrene-butadiene emulsion, 36% styrene-acrylic emulsion, 20% water, 1.5% reinforcing agent, 1.0% antifungal agent, 1.0% defoamer and 0.5% water-repellent %, and then mix and stir the weighed components to make liquid material components.

[0035] 2) each component is weighed by the following percentage by weight: Portland cement 46%, river sand 50%, cellulose ether 0.5%, water reducer 0.8%, organosilicon powder 1.2% and nano silicon oxide 1.5%, then Mix and stir the weighed components to make powder components.

[0036] 3) The prepared liquid material component and the powder material component are mixed and stirred at a weight ratio of 1:2 to form vitrified tile adhesive.

[0037] 4) Construction of vitrified tile adhesive: place the vitrified tile flat on the ground, first use hard scrubber, wire brush, semi-dry towel and other tools to clean off the attachments on the vitrified tile a...

Embodiment 3

[0039] 1) Each component is weighed according to the following percentage by weight: styrene-butadiene emulsion 37%, styrene-acrylic emulsion 34%, water 25%, reinforcing agent 1.5%, antifungal agent 0.5%, defoamer 1.0% and water repellent 1.0% %, and then mix and stir the weighed components to make liquid material components.

[0040] 2) each component is weighed by the following percentage by weight: Portland cement 44%, river sand 52%, cellulose ether 0.8%, water reducer 0.5%, organosilicon powder 1.2% and nano silicon oxide 1.5%, then Mix and stir the weighed components to make powder components.

[0041] 3) The prepared liquid material component and the powder material component are mixed and stirred at a weight ratio of 1:2 to form vitrified tile adhesive.

[0042]4) The construction of vitrified tile back glue: put the vitrified tile flat on the ground, first use a hard brush, wire brush, semi-dry towel and other tools to clean off the attachments on the vitrified tile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com