Method for removing heavy metal Cu in sludge of urban sewage treatment plant in bioleaching mode

A technology of biological leaching and urban sewage, applied in biological sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of high treatment cost, complicated operation, high concentration of energy substances, and achieve the removal effect Good, reasonable design, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

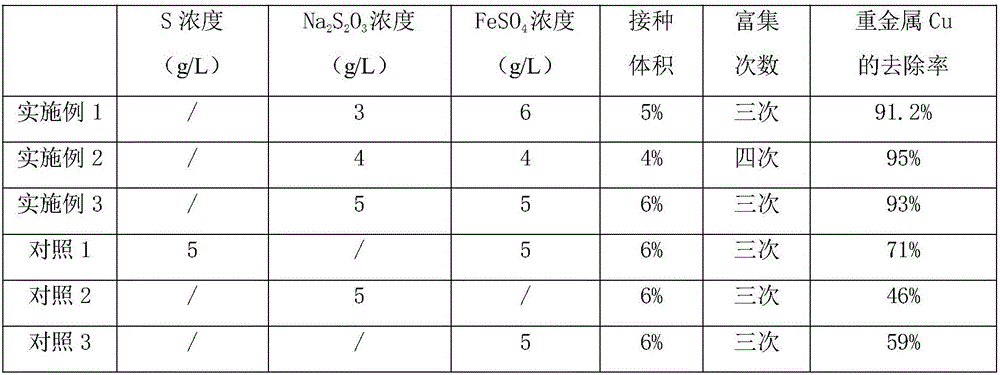

Embodiment 1

[0036] A method for biological leaching to remove heavy metal Cu in urban sewage treatment plant sludge, comprising the steps of:

[0037] (1) The first enrichment culture: take the raw sludge of the sewage treatment plant, add 3g / L Na to the raw sludge 2 S 2 o 3 and 6g / L FeSO 4 As a substrate, enrich and cultivate Thiobacillus thiooxidans and Thiobacillus ferrooxidans inherent in the raw sludge, enrich and cultivate until the pH of the sludge drops below 2.5, and obtain domesticated sludge after the first enrichment and cultivation;

[0038] (2) The second enrichment culture: take the domesticated sludge after the first enrichment culture, inoculate it into the raw sludge by volume ratio 5%, add 3g / L Na 2 S 2 o 3 and 6g / L FeSO 4 As a substrate, it is enriched and cultured under the same conditions until the pH value drops below 2.5 to obtain the domesticated sludge after the second enrichment culture;

[0039] The second enrichment culture is repeated at least once, an...

Embodiment 2

[0048] A method for biological leaching to remove heavy metal Cu in urban sewage treatment plant sludge, comprising the steps of:

[0049] (1) The first enrichment culture: take the raw sludge of the sewage treatment plant, add 4g / L Na to the raw sludge 2 S 2 o 3 and 4g / L FeSO 4 As a substrate, enrich and cultivate Thiobacillus thiooxidans and Thiobacillus ferrooxidans inherent in the raw sludge, enrich and cultivate until the pH of the sludge drops below 2.5, and obtain domesticated sludge after the first enrichment and cultivation;

[0050] (2) The second enrichment culture: take the domesticated sludge after the first enrichment culture, inoculate it into the raw sludge at 4% by volume, add 4g / L Na 2 S 2 o 3 and 4g / L FeSO 4 As a substrate, it is enriched and cultured under the same conditions until the pH value drops below 2.5 to obtain the domesticated sludge after the second enrichment culture;

[0051] The second enrichment culture is repeated at least once, and t...

Embodiment 3

[0060] A method for biological leaching to remove heavy metal Cu in urban sewage treatment plant sludge, comprising the steps of:

[0061] (1) The first enrichment culture: take the raw sludge of the sewage treatment plant, add 5g / L Na to the raw sludge 2 S 2 o 3 and 5g / L FeSO 4 As a substrate, enrich and cultivate Thiobacillus thiooxidans and Thiobacillus ferrooxidans inherent in the raw sludge, enrich and cultivate until the pH of the sludge drops below 2.5, and obtain domesticated sludge after the first enrichment and cultivation;

[0062] (2) Enrichment culture for the second time: take the domesticated sludge after the first enrichment culture, inoculate it into the raw sludge by volume ratio 6%, add 5g / L Na 2 S 2 o 3 and 5g / L FeSO 4 As a substrate, it is enriched and cultured under the same conditions until the pH value drops below 2.5 to obtain the domesticated sludge after the second enrichment culture;

[0063] The second enrichment culture is repeated at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com